Generally, the drilling bottom hole assembly (BHA) is one of the components of the Drilling String, which is below the Drill Pipes. The most common components of the BHA are drill collars, stabilizers, shock Absorbers, jars, reamers, heavy-weight drill pipes, and the drilling bit.

The Bottom Hole Assembly BHA aims to drill a usable hole economically. This objective is achieved with the proper drill bit selection and drill collar selection, which are required to provide high WOB bit weights to improve ROP (The penetration rate).

Stabilizers are one of the bottom hole assembly BHA components needed to minimize the rate of hole angle change and prevent the formation of doglegs and key seats.

In addition, shock absorbers play an important part in prolonging the service life of the bit and drill pipe. Downhole drilling jars may be needed to unstick the BHA.

The Bottom Hole Assembly BHA design is based upon the requirements of having enough weight transfer to the bit (WOB) to be able to drill and achieve a sufficient Penetration Rate (ROP), giving the Driller or Directional Driller directional control to drill as per the planned well trajectory and also to include whatever.

Logging While Drilling (LWD) / Measurement While Drilling (MWD) tools for formation evaluation. As such, bottom-hole assembly BHA design can vary greatly from simple vertical wells with little or no LWD requirements to complex directional wells that must run multi-combo LWD suites.

Before running a BHA, most oilfield service providers have software to model the BHA behavior, such as the maximum WOB achievable, the directional tendencies & capabilities, and even the natural harmonics of the assembly to avoid vibration by exciting natural frequencies.

Main Categories Of Bottom Hole Assembly BHA Used In Oilfield

Rotary Bottom Hole Assembly BHA Drilling

Rotary assemblies are commonly used where formations are predictable and rig economics are an issue. In such an assembly, the weight of the drill collars gives the BHA the tendency to sag or flex to the low side of the hole; collar stiffness length and stabilizer diameter and placement are engineered to control the flex of the BHA. This will bring about the desired hold, build, or drop tendency.

The ability to vary the directional tendency of the assembly comes from varying the weight on the bit. A fixed assembly has only one directional tendency. The weight on the bit allows you to tune that tendency

Directional Bottom Hole Assembly BHA Drilling:

You may need to use a mud motor with a bent sub or use rotary steerable systems

Bottom Hole Assembly BHA Drilling Components:

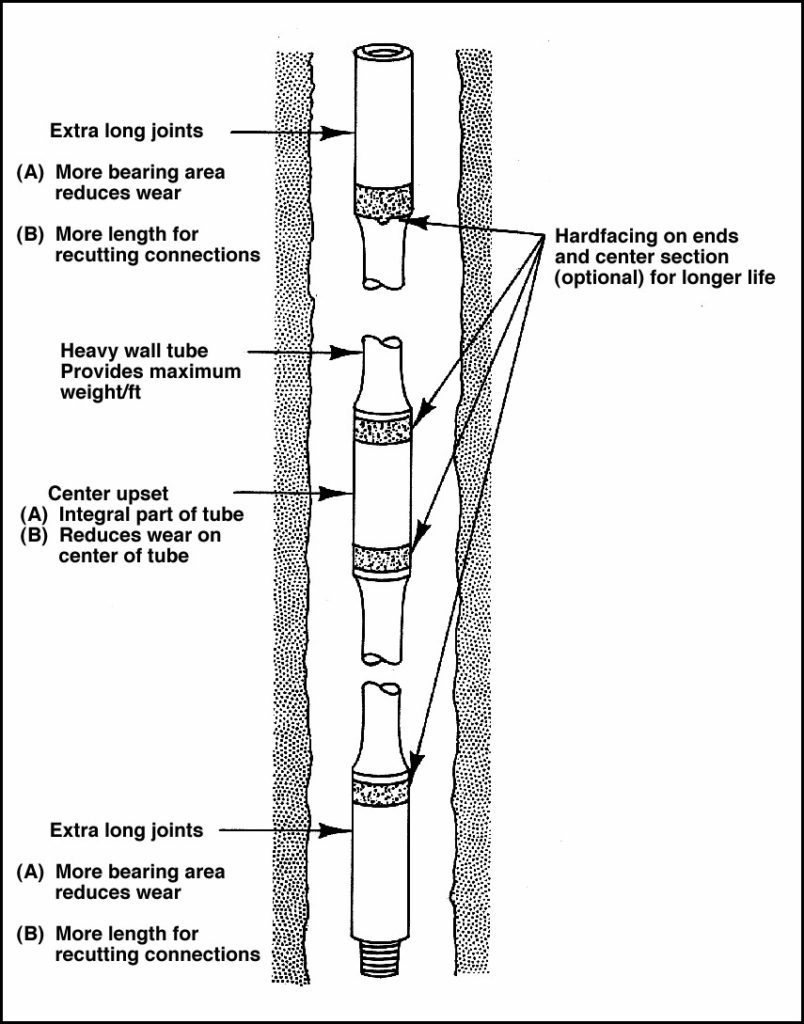

Heavy Weight Drill Pipe (The uppermost BHA Component)

Typically, heavy Weight Drill Pipe Specs are important to understand as it is the entrance of the heavyweight drill pipe design. This article will discuss its specs and how to select the drill string design. In addition to that, we will talk about its main functions. You can also download the spec sheets from any size of heavy-weight drill pipes.

Drill Collar (a predominant component of the BHA components)

Drill collars (D/C) are large diameter-small bore steel pipes with great weight and stiffness. While designing BHA, drilling engineers place D/Cs above the Drilling Bit as D/Cs are the predominant component of the BHA components. Therefore, to select the proper D/C, you must have all information about Drill collar Weights, Size, Specs, Definition, lengths & Types.

Stabilizers :

Drilling stabilizer types & design is the main subject of this article. First, we will define a stabilizer as one of the bottom-hole assembly BHA components. Then, we will move to the stabilizer application. And finally, we will talk about its types.

Reamers

In general, drilling reamer types are the subject of our article. We can say that reamers are under-reamers, roller reamers, RFID reamers, near-bit reamers, and expandable reamers.

Shock Absorbers

Main Headings :

- What Is The Meaning Of Shock Absorbers

- Shock Absorbers Application

- What Are The Drilling Bit Oscillations

- How To Use Shock Absorber To Eliminate The Drilling Bit Oscillations

- The Limitations Of Drilling Shock Absorbers

- Positioning Of Drilling Shock Absorbers In The Drilling String Bottom Hole Assembly BHA

- Drilling Shock Absorber Mechanism

Jarring Devices

Drilling jar placement design is important while drilling. In general, jars are one of the bottom hole assembly BHA components that generate upward or downward impact loads to free stuck pipes or release a fish (Fishing In Drilling Oil & Gas). Many factors affect when to use jars and where to position them for maximum benefit.

Drilling Bit

Drilling Bits article includes many articles covering what you must understand: Bits types, selection, and design.

Main Headings:

- Types Of Drilling Bits: Rolling Cutter Bits, Fixed Cutter Bits (PDC Drill Bits)

- Bit Dull Grading

- Drill Off Test

- Penetration Rates

Drill Pipes ( Not Bottom Hole Assembly BHA Components)

Drill pipes are not one of the bottom hole assembly BHA components, but we shall mention it as a drill string component. This article mainly explains the drill pipe specifications in simple points to help you understand how to select the drill string’s drill pipes.:

- Drill Pipe OD

- Drill Pipe Nominal Weight

- The Pipe Grade

- The tool joint and type of upset

- Drill Pipes Tool Joints Types / Upset Types

- The type of connection

- The classification of drill pipe is based on wear.

- API Drill Pipes Classifications

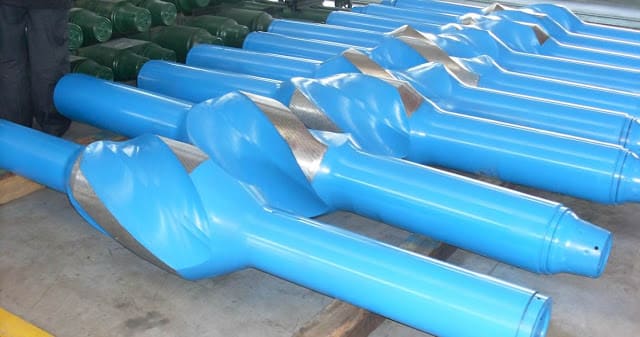

Hole Openers

In drilling, we usually use a hole opener when there is a requirement for a smaller diameter pilot hole at a particular depth, even though we can use regular drilling bits for the successive hole sections. It is an attachment designed to fit onto the drill string, especially for directional drilling. Hole openers are also crucial in horizontal drilling, where larger diameter holes improve wellbore stability and productivity. In addition, there are various designs of hole openers, each with specific features and advantages. Most hole openers come with regular pin-up connections that allow them to be screwed into bit subs or near-bit reamers. It is essential to have a crossover to the drilling rig, in case a bit sub is not available.

How Drilling BHA Act / BHA Behaviour

Generally, rotary BHA Types are designed to build, drop, or hold angles. In addition, the behavior of any rotary assembly is governed by the size and placement of stabilizers within the first 120 ft from the bit.

Additional stabilizers running higher on the drill string will have a limited effect on the assembly’s performance. Also, rotary assemblies are not “steerable”; a rotary assembly’s azimuth behavior (right/left turn) is nearly uncontrollable.

Second, each rotary assembly has a unique build/drop BHA tendency that cannot be adjusted from the surface. Thus, a tripping pipe for the assembly change is required to correct the wellbore course.

Rotary BHA Types

The Main Rotary BHA Types are Slick assembly, fulcrum, and Pendulum Assembly.

How much your company charges to make BHA of vertical and directional wells

How much is for well planning using landmark or compass softwares