What Is The Definition Of Drill Bit Journal Pin?

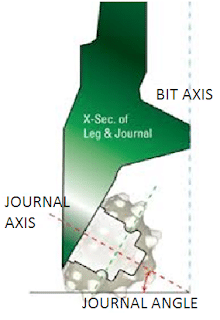

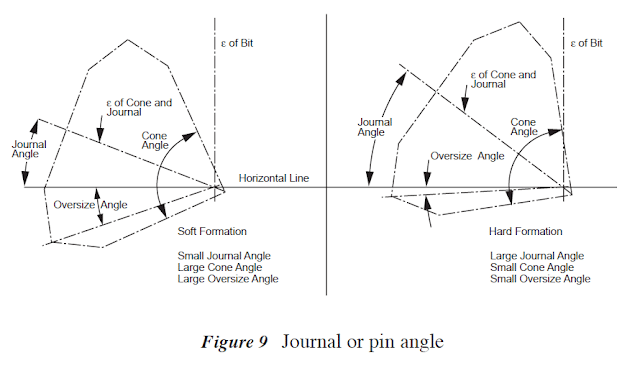

The Drill Bit journal pin is an integral part of the bit leg that provides the connecting point between the bit cone and the body. The pin is machined in a manner to accept the bearings and, in the case of the journal-bearing bit, is precision machined so it can serve as a metal-to-metal bearing. In other words, The journal angle in the drilling bit can be defined as it is the angle that formed between the axis of the journal and the horizontal. Since all three cones fit together, the journal angle specifies the outside contour of the bit.

How Drilling Bit Journal Angel Affect Drill Bit Design

- Well Control On Rigs: 15 – Checks & Tests

- Snubbing Units In Oil & Gas Field

- Casing Running Procedures Good Practice

- Drill String Design Calculation Steps

- BHA Design For Oil & Gas Wells

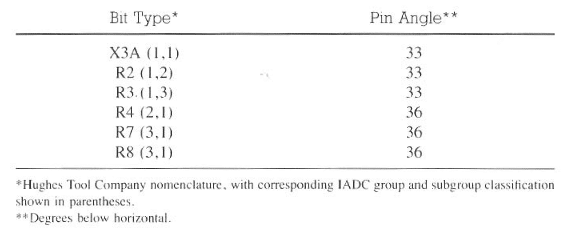

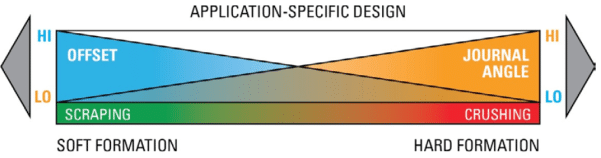

The angle of the journal pin from the horizontal varies, depending on the type of the rock the bit is designed to drill. Hard-formation bits that are generally subjected to high bit weights have the pin oriented so it can accept the greater vertical component of the bit load. This concept is shown in Fig. 2 and Table 1.

The use of an Oversize Journal Angle in drill bit increases the diameter of the cone and is most suitable for soft formation bits. Although this increases cone size, the gauge tip must be brought inwards to ensure the bit drills a gauge hole.

| FORMATION TYPE | JOURNAL ANGLE | REMARKS |

| SOFT | 33° | Low journal angle allows a prominent cutter action and permits greater tooth depth. |

| MEDIUM | 34° to 36° | Decreases cutter action |

| HARD | 39° | Minimizes cutter action |

Degree Of Meshing Or Interfit

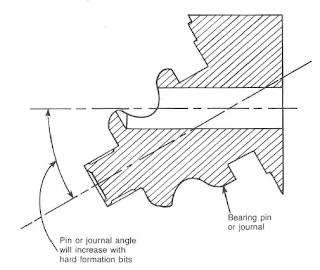

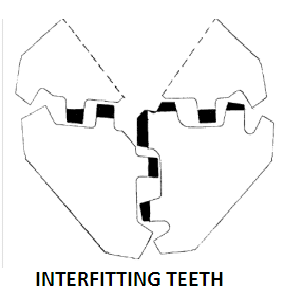

One important factor which affects drill bit journal angle is the degree of meshing or interfit (i.e. the distance that the crests of the teeth of one cone extend into the grooves of the other).

The effect of the amount of interfit due to journal angle on bit design:

- It allows increased space for tooth depth, more space for bearings and greater cone thickness

- It allows mechanical cleaning of the grooves, thus helping to prevent bit balling

- It provides space for one cone to extend across the centre of the hole to prevent coring effects

- It helps the cutting action of the cones by increasing cone slippage.

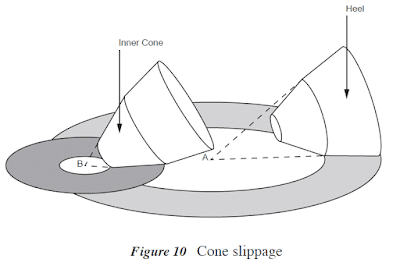

In some formations, it is advantageous to design the cones, their configuration and journal angle in drill bit so that they do not rotate evenly but that they slip during rotation. This Cone slippage, as it is called, allows a rock bit to drill using a scraping action, as well as the normal grinding or crushing action.

Drilling Bits Offset Angles

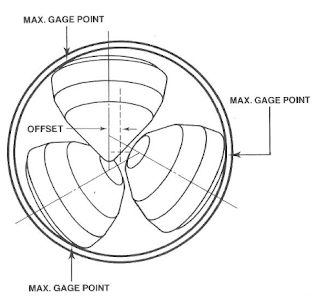

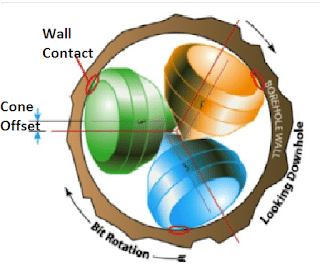

Another design feature of the bearing pin is the angle between the center line of the pin and the geometric center of the bit, as shown in Fig.4. The cone offset from the center of the bit causes the cone to drag across the formation and creates additional shearing actions, termed skew. As harder rocks are drilled, the degree of cone offset for the various types of bits decreases since compressive failure becomes the primary drilling mechanism instead of shearing. Too much skew will cause the bit to wear quickly in hard formations.

Again, The cones are mounted on bearings which run on pins that are an integral part of the bit body. The drilling action of a rolling cutter bit depends to some extent on the offset of the cones. As shown in Fig.5 , the cone offset of the bit is a measure of how much the cones are moved so that their axes do not intersect at a common point in the center of the hole.

How Drilling bit Offset Affect Drilling Soft And Hard Formation?

Offsetting causes the cones to slip as they rotate and scrape the hole bottom much like a drag bit. This action tends to increase penetration rate in soft formations. In hard formations where the rock must be fractured or broken, scraping contributes little to rock removal. In addition scraping against a hard formation is very abrasive and can wear the teeth down quickly. For these reasons hard formation bits are designed with little or no cone offset.

| FORMATION TYPE | CONE OFFSET | REMARKS |

| SOFT | Maximum offset (3° Skew Angle) | Increases gouging, scraping action |

| MEDIUM | Limited offset (2° Skew Angle) | Limited cutter action |

| HARD | No offset (0° Skew Angle) | Minimized gouging, scraping action |

In brief, Cone offset angle is expressed as the angle the cone axis would have to be rotated, to make it pass through the center line of the hole. Cone offset angles vary from 4 degrees for bits used in soft formations to zero for bits used for extremely hard formations.

The Effect Of Journal Angle And The Cone Offset Angle On Drill Bit Cone Geometry

Basic cone geometry is directly affected by increases or decreases in either drill bit journal or offset angles, and a change in one of the two requires a compensating change in the other. Skidding-gouging improves penetration in soft and medium formations at the expense of increased insert or tooth wear. In abrasive formations, offset can reduce cutting structure service life to an impractical level. Bit designers thus limit the use of offset so that results just meet requirements for formation penetration.

Cone Slippage How To Design It Using Journal Angle And Cone Offset

Cone Slippage can be designed into the bit in two ways. Since cones have two profiles: the inner and the outer cone profile, a cone removed from the bit and placed on a horizontal surface can take up two positions. It may either roll about the heel cone or the nose cone. When the cone is mounted on a drill bit journal it is forced to rotate around the center of the bit. This “unnatural” turning motion forces the inner cone to scrape and the outer cone to gouge. Gouging and scraping help to break up the rock in a soft formation but are not so effective in harder formations, where teeth wear is excessive.

Cone slippage can also be attained by offsetting the axes of the cones. This is often used in soft formation bits. To achieve an offset the journals must be angled slightly away from the center. Hard formation bits have little or no offset to minimise slippage and rely on grinding and crushing action alone.