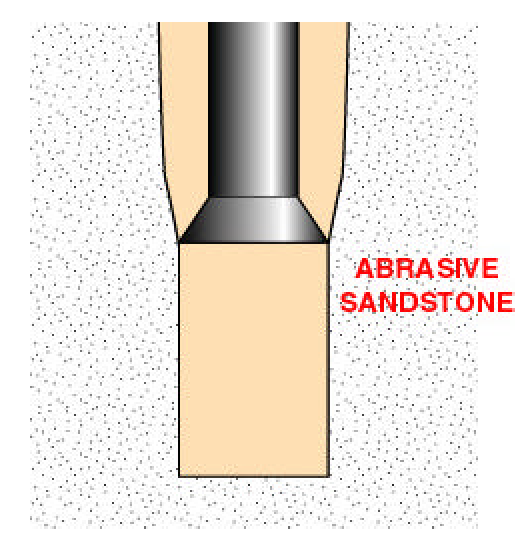

Undergauge Hole in drilling is a phenomenon that means that the drilled hole diameter is less than the used Drilling Bit diameter. It always happens after the Drilling Bit, and the stabilizer gauges get worn while drilling abrasive rock, so the following section using the same Drilling Bit will produce a less diameter hole or under gauge hole. And if it was decided to run new in gauge Drilling Bit after that, it will have difficulty to run in the last under gauge section, and reaming will be required to pass this undergauge section. If it was decided to run quickly without reaming, the Drilling Bit can jam in the undergauge hole, and the pipe becomes Stuck.

A plastic formation may also cause undergauge holes. After being penetrated by the Drilling Bit with a fluid giving a hydrostatic pressure less than the overburden, which is the usual pressure of the plastic formation, this formation deforms, causing the hole to close. One of the formations which most often causes such a situation is moving salt.

The only preventive measure is to use a drilling fluid dense enough to give overburden pressure at a depth of the salt. This will usually be impossible due to the risk of creating fractures elsewhere in the hole. In that case, the drilling fluid density should be kept as high as feasible, as the flow rate of the salt is proportional to the pressure difference. If the Drill String becomes Stuck, the solution (!) is simple – a pill of fresh water. If this is done, the effect of introducing a light fluid on well control aspects must be considered. But here we will talk about the undergauge hole caused mechanically.

When Undergauge Hole Happens While Drilling

So we can summarize when the undergauge hole happens into simple points.

- After using a new Drilling Bit.

- Coring is one method of collecting rock and sediment samples for geological research. Some coring heads are often slightly smaller than bit sizes and will produce undergauge holes so reaming is preferred for the cored sections.

- When changing bits from Roller Cone Bit To PDC Bit in the same section.

- When drilling hard abrasive rocks. The wearing speed of the drilling bit will increase and will lead to drill with a worn, less-diameter drilling bit. So It is a good practice to check your Bit Dull Grading after POOH.

- By plastic formations (we will not talk about this for now)

Preventative Action To Avoid Undergauge Hole

- Choose the suitably gauge-protected Drilling Bits and Stabilizer according to the formation that will be drilled.

- Think about Roller Reamers. You can check The effect of using an under reamer to have in gauge hole case study.

- Always gauge all Bottom Hole Assembly BHA components before RIH and after POOH.

- Ream suspected undergauge sections.

- Tripping Pipe in slowly before the Bottom Hole Assembly BHA enters an undergauge section.

What Are The Indications For Undergauge Hole?

- Its reason is the undergauge of Drilling Bits and Drilling Stabilizers, so the first thing will be the pulled Drilling Bit or Stabilizers are undergauge.

- And as it will happen after RIH with new in gauge Drilling Bit, the second indicator will be when RIH.

- Sudden set-down weight.

- Circulation is unrestricted or slightly restricted.

- As the under gauge hole may happen after coring operations, Drilling Bit may get Stuck at the top of a cored section.

Freeing Procedure For Stuck Caused By Under Gauge Hole

You can consider the following tips while freeing such type of Stuck Pipe

- Jarring up with the maximum trip load.

- Do not Jar down.

- Consider the use of an acid pill.

- Consider applying torque as a last resort. But consider that Drill Pipe, Heavy Weight Drill Pipe HWDP yield strength will be affected by such torque and will be decreased.

References:

- Drilling Handbook For Stuck Pipe – 2001