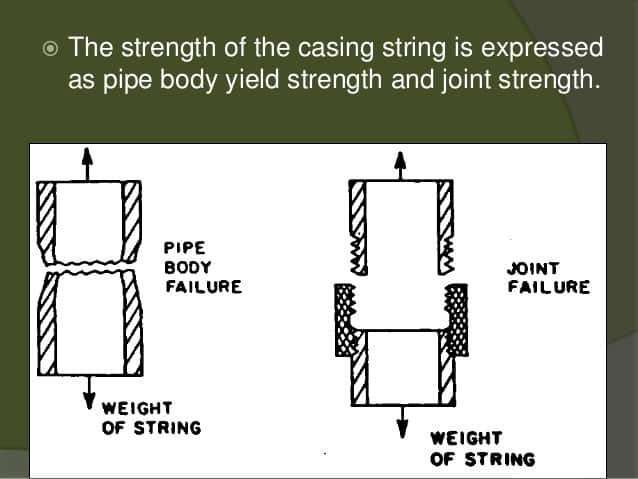

Casing Tensile Strength

The tensile load of the pipe is the weight of the casing which acts to pull the pipe apart. The tension is always the greatest at the surface and decreases with depth due to the casing weight below the point of interest.

In designing a casing string the upper most joint of the string is considered to have the maximum load on it since it has to carry the total weight of the casing string. Tensile loads are used to select pipe couplings.

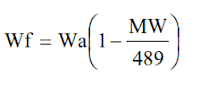

Tension loads are computed using the buoyant forces acting on the pipe and the pipe weight. The buoyancy force acts on the bottom joint of the casing and results in a reduction in the hanging weight of the casing. The buoyant forces are defined as the forces acting on submerged equipment due to hydrostatic pressure. The weight of the casing in fluid is given by:

where,

Wf = weight in fluid

MW = mud weight in pcf

Wa = weight in air

The pipe body yield strength is calculated by:

Ften(lb) = 0.7854 x Ym (De²- Di²)

where:

Di is the ID of the casing.

Example for casing tensile loads calculations:

Calculate the body yield strength of 7 in, 26-lb/ft J-55 casing with long threads & couplings (LT&C).

Solution:

The body yield strength is:

Ften (lb) = 0.7854 x 55,000 [(7)²- (6.276)²] = 415,200 lb.

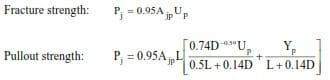

Casing Joint Strength Calculations

To calculate the joint strength of a given thread depends on grade, size and weight of the casing and on the effective size of the threads.

Below there are two formulas:

1- The first one is for minimum strength of a joint failing for fracture

2- The Second one is for minimum strength for a joint failing for thread pullout.

The lesser of the two values govern.

Where:

- Pj = minimum joint strength, lb.

- Ajp = cross sectional area of pipe under the last perfect thread at pin, sq. in. = 0.7854 [(D-0.1425)²- d²] for eight round threads

- D = nominal outside diameter of pipe, in.

- d = nominal inside diameter of pipe, in.

- L = engaged thread length, in.

- Yp = minimum yield strength of pipe, psi.

- Up = minimum ultimate strength of pipe, psi.

I’m no longer positive the place you are getting your info,

but great topic. I must spend some time finding out much more

or figuring out more. Thank you for excellent info

I was in search of this info for my mission.

I every time emailed this webpage post page to all my friends, since if like to read it then my contacts

will too.

Awesome post.

Wow! At last I got a web site from where I can truly obtain useful facts concerning my study and knowledge.