When encountering losses, the priority is to determine the type of mud losses which will help you choose the suitable size and material for bridging or plugging material for the loss zone. Below is how to differentiate between them:

- Losses into the formation structure are usually indicated by an increasing loss rate as drilling exposes more formation

- Losses into a fracture are usually sudden.

Bridging Material Mechanism In Formation Structure Losses

If losses are into the formation structure then our task will be as follows:

- Firstly, plug the pore throats with larger-sized particles first (Coarse LCM material),

- Secondly, plug the channels between the larger-sized particles with medium-sized particles (Medium LCM)

- Finally seal the channels between the medium-sized particles with a filter cake of small- sized particles (Fine LCM).

Barite and drilled solids (cuttings) also contribute to this bridging process.

There is a correlation between pore size (in microns) and formation permeability (in milli-Darcies), as follows:

Pore Size = √ (Formation Permeability)

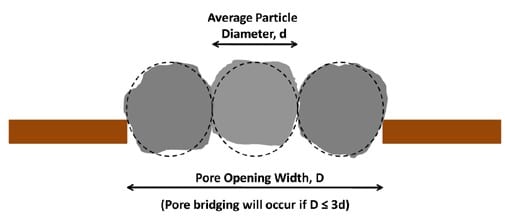

Research also confirms that particles with an average diameter one third the size of the pore throat diameter will form a bridge across the pore throat when subjected to differential pressure ( below diagram) which is provided by the over-balance between hydrostatic pressure and the pore pressure.

With this knowledge, effective LCM treatments can be formulated by measuring the permeability or pore throat size from core samples obtained from representative offset oil and gas wells.

Particle Size Distribution (PSD)

The bridging and LCM materials used in drilling oil & gas wells are generally categorized as follows:

- Fine

- Medium

- Large.

However, the particles in each category will range in size and this is called the Particle Size Distribution. Sophisticated electronic laboratory equipment is available for measuring the PSD of bridging materials in a fluid (e.g. laser diffraction technology), and the concentrations of these materials can then be adjusted to suit the formation being drilled in order to produce a low permeability filter cake.

Common particle size ranges for CARB Bridging Material grades are as follows:

- Fine: 5 to 400 microns

- Medium: 100 to 1000 microns

- Coarse: 60 to 2500 microns

- Ground Marble Grade E: 1 to 160 micron

Most Barite particles range from 2 to 44 microns and will therefore provide effective bridging for pore throat sizes ranging up to 132 microns, so pore sizes above this will require LCM bridging materials.

Based on the relationship between pore size and permeability, 2-micron Barite particles will theoretically bridge 6-micron pore throats, which equate to a 36 milli-Darcy permeability. Similarly, 44-micron Barite particles will theoretically bridge 132-micron pore throats, which equate to a 17,424 milli-Darcy (i.e. 17 Darcy) permeability.

The PSD for Barite includes particles that are larger than 44 microns, so Barite is therefore effective for bridging high permeability sands before whole mud starts to be lost to the formation. As a general guideline, whole mud losses do not occur in formations with permeabilities below 50 Darcies when Barite is used as a weighting agent.