The performance of a bit may be judged on the following criteria:

- How much footage it drill (ft).

- How fast it drilled (ROP).

- How much does it cost to run (the capital cost of the bit plus the operating costs of running it in the hole) per foot of the hole drilled?

Cost Per Feet

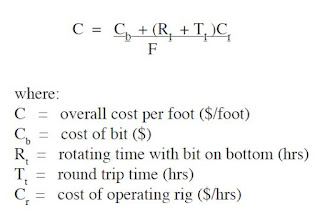

Since the aim of bit selection is to achieve the lowest cost per foot of hole drilled the best method of assessing the bits’ performance is the last of the above. This method is applied by calculating the cost per foot ratio using the following equation:

This equation relates the cost per foot of the bit run to the cost of the bit, the rate of penetration and the length of the bit run. It can be used for:

- Post-drilling analysis to compare one bit run with another in a similar well.

- Real-time analysis to decide when to pull the bit. The bit should be pulled theoretically when the cost per foot is minimal.

Factors Affect PDC Bit Performance

WOB/RPM

- PDC drill bits tend to drill faster with low WOB and high RPM.

- They are also found to require higher torque than roller cone bits.

- The general recommendation is that the highest RPM that can be achieved should be used.

- Although the torque is reasonably constant in shale sections, the bit will tend to dig in and torque up in sandy sections. When drilling in these sandy sections, or when the bit drills into challenging sections and the penetration rate drops, the WOB should be reduced but maintained to produce a rotary torque equal to that of a roller cone bit.

- Too low a WOB will cause premature cutter wear, possible diamond chipping, and a slow rate of penetration.

Mud Properties

The best ROP results have been achieved with oil based muds but a good deal of success has been achieved with Water Based Mud.

Reasons for the improved performance in oil-based muds have been attributed to increased lubricity, decreased cutter wear temperature, and preferential oil wetting of the bit body. The performance

of PDC bits in respect to other mud properties is consistent with that found with Roller Cone Bits i.e. increase in mud solids content or mud weight decreases ROP.

Hydraulic Efficiency

The effects of increased hydraulic horsepower at the bit are similar to their effect on Roller Cone Bits. However, manufacturers will often recommend a minimum flow rate in an attempt to ensure that the bit face is kept clean and cutter temperature is kept to a minimum. This requirement for the flow rate may adversely affect the optimization of HHP.