In the drilling industry, the rate of penetration (ROP), also known as penetration rate or drill rate, is the speed at which a drilling bit breaks the rock under it to deepen the borehole. It is generally measured in feet per minute or meters per hour.

Generally, ROP increases in fast-drilling formations such as sandstone (positive drilling break) and decreases in slow-drilling formations such as shale (reverse break). ROP decreases in shale due to diagenesis and overburden stresses. Over-pressured zones can give twice of ROP as expected,, which indicates a well kick. Drillers need to stop and do the bottoms up.

The penetration rate that can be achieved by a bit has an inverse effect on the drilling cost per foot. The main factors that affect the penetration rate are

- bit type

- formation properties

- drilling fluid properties

- bit weight and rotary speed

- bit hydraulics

Bit Types & Drilling Penetration Rate

The bit type selection has a significant effect on the rate of penetration. For rolling cutter bits, the initial penetration rates for shallow depths are often highest when using bits with long teeth and a large cone offset angle. However, these bits are practical only in soft formations because of rapid tooth wear and sudden decline in penetration rate in harder formations. The lowest cost per foot drilled is usually obtained when using the longest tooth bit that will give a tooth life consistent with the bearing life at optimum bit operating conditions.

The diamond and PDC bits are designed for a given penetration per revolution by selecting the size and number of diamonds or PDC blanks. The width and number of cutters can be used to compute the effective number of blades. The length of the cutters projecting from the face of the bit (less the bottom clearance) can limit the depth of the cut. The PDC bits perform best in soft, firm, and medium-hard, nonabrasive formations that are not gummy. Therefore, the bit type selection must be considered, i.e., whether a drag bit, diamond bit, or roller cutter bit must be used, and the various tooth structures affect the drilling rate obtainable in a given formation to some extent.

RPM & Drilling Penetration Rate

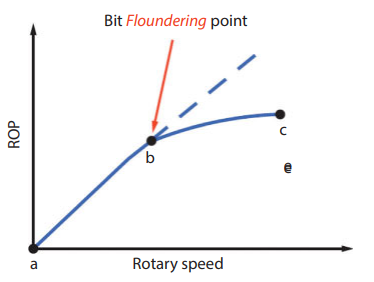

Figure 2.19 shows a typical response curve for ROP (rate of penetration) plotted against rotary speed, where all other drilling variables are kept constant. The penetration rate usually increases linearly at low rotary speeds (segment ab). However, at higher rotary speeds (after point b, segment b to c), the rate of increase in ROP slows down.

This poor response of penetration rate at high rotary speeds is often attributed to less efficient bottom-hole cleaning. This, in turn, leads to bit floundering due to poor cleaning of the drill cuttings.

2015)

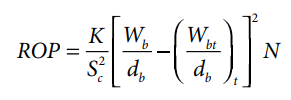

In 1962, Maurer came up with a theoretical equation that connects the rate of penetration (ROP) of rolling cutter bits to the rock strength, bit weight, bit size, and rotary speed. The equation was based on observations made in single-insert impact experiments, where it was found that the volume of the crater is proportional to the square of the depth of cutter penetration, and the depth of cutter penetration is inversely proportional to the rock strength. Under these conditions, Maurer’s equation can be expressed as follows:

Where:

- ROP = rate of penetration, ft. /min

- Sc= compressive strength of the rock

- Wbt = threshold bit weight

- Wb= bit weight

- db= bit diameter

- N = rotary speed (Wbt/db)

- K = constant of proportionality

- t= threshold bit weight per inch of bit diameter

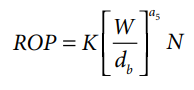

This theoretical relation assumes perfect borehole cleaning and incomplete bit tooth penetration. Bingham (1965) suggested the following drilling equation on the basis of considerable laboratory and field data. The equation can be written as:

Where:

- a5 = bit weight exponent.

In this equation, the threshold bit weight was assumed to be negligible, and the bit weight exponent must be determined experimentally for the prevailing conditions.

Formation Characteristics

- The ultimate compressive strength of the rock is the most essential rock property that affects penetration rate. The higher the compressive strength, the lower the penetration rate.

- The mineral composition of the rock has some effect on the penetration rate. Rocks that contain abrasive minerals can cause rapid dulling of the bit teeth. Rocks that contain gummy clays can cause the bit to ball up and drill inefficiently.

- The permeability of rock also affects the penetration rate. In permeable rocks, the drilling fluid filtrate can move into the rock ahead of the bit, equalize the pressure differential acting on the chips formed beneath each tooth, and increase the penetration rate.

Drilling Fluid Properties

Drilling fluid properties that affect penetration rate are

- Density.

- Rheological properties.

- Filtration properties.

- The solids content and size distribution.

Density

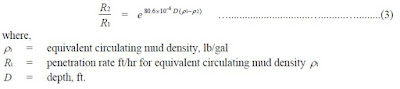

- An increase in the drilling fluid density would decrease the penetration rate. Increasing the drilling fluid density would cause an increase in the bottom hole hydrostatic pressure beneath the bit and thus increase the differential pressure (overbalance) between the borehole and the formation pore pressure.

- An increase in the differential pressure would increase the strength of the rock and, therefore, decrease the penetration. Also, a higher differential pressure prevents the ejection of the crushed fragments of rock formed beneath the teeth of the bit, resulting in a lower penetration rate.

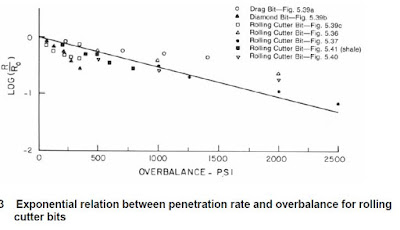

- The effect of differential pressure on the penetration rate in Berea sandstone is shown below. Note that the effect of overbalance on penetration rate is more pronounced at low values of overbalance than at high values of overbalance. If the overbalance is quite large, an additional increase in overbalance has little effect on the penetration rate.

Mud Rheology

- Penetration rate tends to decrease with increasing viscosity and solids content and increase with increasing filtration rate.

- Increasing the viscosity increases the frictional losses in the drillstring and thus decreases the hydraulic energy available at the bit for cleaning the bottom of the hole.

Solid Content

The solid content of the mud controls the pressure differential across the zone of crushed rock beneath the bit. Increasing the solid content decreases the filtration rate and increases the differential pressure. As mentioned earlier, an increase in the differential pressure results in a decrease in the penetration rate.

Effect Of Differential Pressure on Drilling Penetration Rate

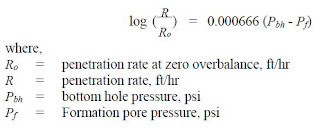

Many studies have been conducted on the effect of differential pressure (overbalance) on the penetration rate. Bourgoyne and Young observed that the relation between differential pressure and penetration rate could be represented by a straight line on a semi-log paper, as shown below. The equation for the straight line is given by

Rig Efficiency

Ensuring the drilling rig and its equipment are maintained with integrity is crucial in achieving an efficient Rate of Penetration (ROP) and minimizing drilling problems. It is important to have proper rig hydraulics, such as mud pump power, for efficient bottom and annular hole cleaning and hoisting power for efficient tripping pipe out. The derrick design loads and drilling line tension must be considered to allow safe overpull in case of a sticking problem.

Well-control systems, including ram preventers, annular preventers, and internal preventers that allow kick control under any kick situation, are necessary to reduce drilling problems and optimize ROP. Monitoring and recording systems that track trend changes in all drilling parameters are also crucial for rig efficiency. These systems can retrieve drilling data at a later date. Proper tubular hardware that can handle all anticipated drilling conditions and effective mud handling and maintenance equipment will ensure that the mud properties are designed for their intended functions.

Terminating a Bit Run

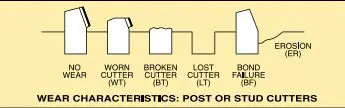

The decision to terminate a bit run is not always straightforward in drilling operations. A bit should be pulled out if the bearings are worn out, or the cutters have worn out, so it is no longer economical to continue drilling with the bit.

Badly worn bearings can be detected by monitoring the rotary table torque. When bearings are worn, one or more of the bit cones will lock and cause a sudden increase in the rotary torque needed to rotate the bit. When this happens, the bit should be pulled out. When the penetration rate decreases rapidly as bit wear progresses, it may be advisable to pull the bit before it is completely worn.

If the lithology is somewhat uniform, the total cost can be minimized by minimizing the cost of each bit run. In this case, the best time to terminate the bit run can be determined by keeping a current estimate of the cost-per-foot for the bit run, assuming that the bit would be pulled at the current depth. Even if significant bit life remains, the bit should be pulled when the computed cost-per-foot increases.

However, if the lithology is not uniform, this procedure will not always yield the minimum total healthy cost. In this case, an adequate criterion for determining optimum bit life can be established only after enough wells are drilled in the area to define the lithologic variations.

References

- [Hossain, M. Enamul] Drilling Engineering Problems Book

- [Mitchell R.F., Miska S.Z.] Fundamentals of Drilling

Tools quality most important