All types of drilling bits used in oil and gas have seen perhaps more technological advancements over the past years than any other type of drilling equipment. These advancements include such items as:

- Development of the roller cone bit.

- Multiple cone and jet arrangements in roller bits.

- Cone lubrication methods.

- Diamond bit drilling and coring procedures.

- Polycrystalline (PDC) drilling bits.

Each of these advancements represents a significant improvement over previous designs, and they tend to increase the effectiveness of the drilling process.

Oil & Gas Field Drilling Bits Types

Rotary bits drill the formation using primarily two principles:

- Rock removal by exceeding its shear strength and

- Removal by exceeding the compressive strength.

The broken rock is removed by rotary scraping or hydraulic cleaning. Either process can also contribute to the initial breakage. Most drilling operations can be divided accordingly into shear failure or compressive failure.

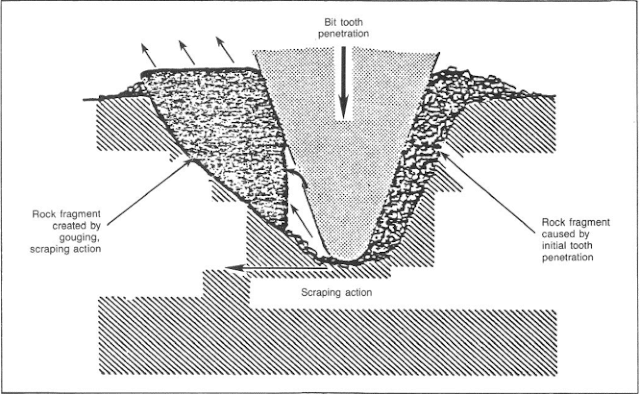

Shear failure involves using a bit tooth to shear or cut the rock into small pieces so it can be removed from the area below the bit. The simple action of forcing a tooth into the formation creates some shearing and results in cuttings development. In addition, if the tooth is dragged across the rock after its insertion, the effectiveness of the shearing action will increase (see Fig.1). The Shear failure mechanism requires, however, that the formation exhibits a low compressive strength that will allow the insertion of the tooth.

To illustrate the type of shear failure used to drill softer formations, imagine that a knife blade is inserted into a piece of firm clay. As the blade is inserted, it creates small clay fragments near the cutting surface. More fragments can be developed if the knife blade is twisted after penetrating the clay. This penetrating-twisting mechanism describes the principles involved in most soft-formation bits.

As the compressive strength or abrasiveness of the formation increases, the shearing-twisting action is reduced. Rocks with high compressive strengths generally prevent the insertion of a tooth that would have initiated the shearing action. In addition, rocks with a high abrasiveness quickly wear a bit tooth if twisted or dragged across the formation face. These types of rocks generally require that a compressive failure mechanism be used.

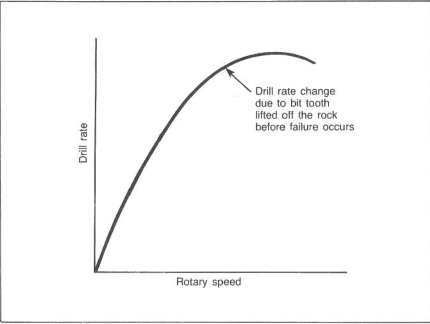

Compressive failure of a rock segment requires that a load be placed on the rock that will exceed the compressive strength of that given rock type. The load must remain on the rock surface long enough for rock failure to occur (see Fig.2). Rock failure by compressive loading will not occur if the compressive strength of the rock exceeds the load or if the load is removed before it is transmitted from the bit tooth to the formation. This is the basis for the hard-rock drilling characteristics of high bit weights and low rotary speeds.

Roller Cone Bits

Introduction

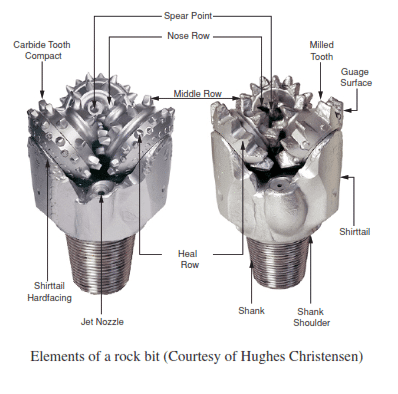

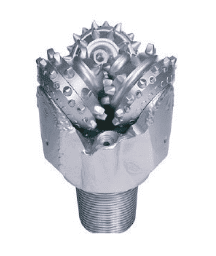

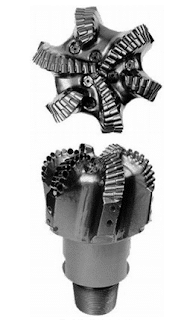

Roller cone drilling bits type (or rock bits) are still the most common type of bit used worldwide in oil and gas fields. The cutting action is provided by cones that have either steel teeth or tungsten carbide inserts. These cones rotate on the bottom of the hole and drill the hole predominantly with grinding and chipping action. Rock bits are classified as milled tooth bits or insert bits depending on the cutting surface on the cones (Figures 2 and 3).

The first successful roller cone bit in the oil field was designed by Hughes in 1909. This was a major innovation since it allowed rotary drilling to be extended to hard formations. The first Roller Cone Bit Design was a two cone bit, which frequently balled up since the teeth on the cones did not mesh. This led to the introduction of a superior design in the 1930s with three cones with meshing teeth. The same basic design is still in use today, although there have been many improvements over the years.

The cones of the 3-cone bit are mounted on bearing pins or arm journals, which extend from the bit body. The bearings allow each cone to turn about its axis as the bit is rotated. The use of 3 cones allows an even distribution of weight, a balanced cutting structure, and drills a better gauge hole than the two-cone design.

The major advances in rock bit design since the introduction of the Hughes rock bit include:

- Improved cleaning action by using jet nozzles

- Using tungsten carbide for hard facing and gauge protection.

- Introduction of sealed bearings to prevent the mud from causing premature failure due to bearings abrasion and corrosion.

Mill tooth bits type:

These types of drilling bits used in oil and gas wells have steel teeth that are milled on the cones. The size and shape of teeth vary according to the formation to be drilled. In soft formation, the teeth are long and slender, whereas in hard formation, the teeth are short and broad.

Insert drilling bits type:

In these drilling bit types, the teeth are not milled into the cones. Instead of that, tungsten carbide inserts are pressed into the cones. These techniques make the bits much harder and can last longer when drilling through hard formations. The size and shape of teeth also depend on the formation to be drilled. The teeth can be long and chisel shapes in soft formation. For hard formations, it can be short and round shapes.

Tungsten carbide is one of the hardest materials known. Its hardness makes it extremely useful as a cutting and abrasion-resistant material for roller-cone bits. The compressive strength of tungsten carbide is much greater than its tensile strength. It is thus a material whose usefulness is fully gained only when a design maximizes compressive loading while minimizing shear and tension. Tungsten carbide is the most popular material for drilling bit-cutting elements. Hard-facing materials containing tungsten carbide grains are the standard for protection against abrasive wear on bit surfaces.

The shape and grade of TCIs are influenced by their respective location on a cone. Inner rows of inserts function differently from outer rows. Inner rows have relatively lower rotational velocities about the cone and bit axes. As a result, they have a natural tendency to gouge and scrape rather than roll. Inner insert rows thus generally use softer, tougher insert grades that best withstand crushing, gouging, and scraping actions. Gauge inserts are commonly constructed of harder, more wear-resistant tungsten carbide grades that best withstand severe abrasive wear. It is thus seen that requirements at different bit locations dictate different insert solutions. A large variety of insert geometries, sizes, and grades through which bit performance can be optimized are available to the designer.

Diamond Drilling Bits Type In Oil & Gas

Diamonds embedded in a matrix have been used since the early Chinese dynasties; however, modern usage for mineral exploration came into common use in the early 1900s. The diamond’s natural wear resistance makes it competitive in today’s drilling practices, even at higher prices. Diamond drilling bits type are used in conventional rotary, turbine, and coring operations in oil and gas wells.

Like any other product, diamond bit designs and applications must be understood to obtain optimum results at economical rates. The combination of fluid hydraulics blended with the selection and arrangement of diamonds enables this goal to be met in most formation types.

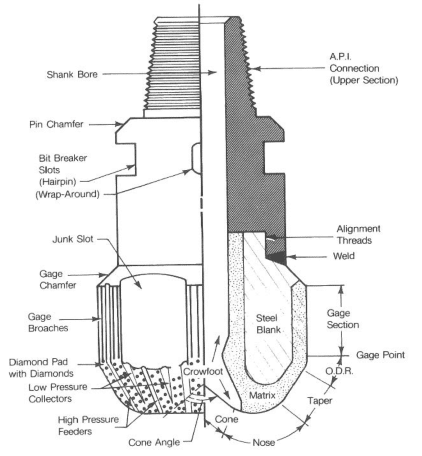

Diamond bits are structured differently than roller cone bits (see Fig.6). A matrix structure is embedded with diamonds and contains waterways from the bit throat to the exterior of the bit. The drilling fluid should flow across the face of the bit to clean the cuttings and cool the diamonds.

Rock failure mechanism with a diamond bit is slightly different than steel tooth or insert bits. The diamond is embedded in the formation and then dragged

Natural Diamond Bits:

The hardness and wear resistance of the diamond made it an obvious material to be used for a drilling bit. The diamond bit is a type of drag bit since it has no moving cones and operates as a single unit.

The cutting action of a diamond bit is achieved by scraping away the rock. The diamonds are set in a specially designed pattern and bonded into a matrix material set on a steel body.

Despite its high wear resistance, the diamond is sensitive to shock and drill string vibration, and therefore, great care must be taken when running a diamond bit.

Effective fluid circulation across the face of the bit is also very important to prevent overheating of the diamonds and matrix material and to prevent the face of the bit from becoming smeared with the rock cuttings (bit balling).

The major disadvantage of diamond bits is their cost (sometimes ten times more expensive than a similar-sized rock bit). There is also no guarantee that these bits will achieve a higher ROP than a correctly selected roller cone bit in the same formation.

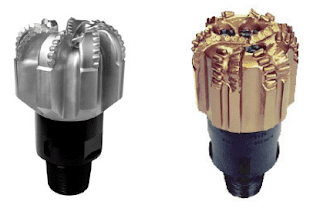

PDC Drilling Bits Type (Polycrystalline Diamond Compact)

A new generation of bit technology began in 1973 when General Electric Co. introduced the Stratapax drill blank. This technology has been licensed to virtually all drill bit manufacturers now producing proprietary PDC (polycrystalline diamond compact) bits. The names generally applied to these bits are PDC or Stratapax. Drill blanks consist of a layer of polycrystalline, manufactured diamond, and cemented tungsten carbide produced as an integral blank by a high-temperature, high-pressure technique (Fig. 7). The resulting blank has nearly the hardness and greater abrasion resistance of natural diamond. It is complemented by the strength and impact resistance of cemented tungsten carbide. Blanks are used as drag-cutting elements attached to bits for drilling and mining applications (Fig. 8).

These bits have the same advantages and disadvantages as natural diamond bits but use small discs of synthetic diamond to provide the scraping cutting surface. The small discs may be manufactured in any size and shape and are not sensitive to failure along cleavage planes as with natural diamonds.

PDC Drilling Bits Design Matrix & Steel: PDC bits are designed and manufactured in two structurally dissimilar styles:

- matrix-body bit and

- steel-body bits.

The two provide significantly different capabilities, and because both types have certain advantages, a choice between them would be decided by the application’s needs. “Matrix” is a very hard, rather brittle composite material comprising tungsten carbide grains metallurgically bonded with a softer, tougher, metallic binder. Matrix is desirable as a bit material because its hardness is resistant to abrasion and erosion. It can withstand relatively high compressive loads but, compared with steel, has low resistance to impact loading. Matrix is relatively heterogeneous because it is a composite material. Because the size and placement of the particles of tungsten carbide vary (by both design and circumstances), its physical properties are slightly less predictable than steel.

Steel is metallurgically opposite of matrix. It can withstand high-impact loads but is relatively soft and, without protective features, would quickly fail by abrasion and erosion. Quality steels are essentially homogeneous, with structural limits that rarely surprise users.

TSP Drilling Bits Type (Thermally Stable Polycrystalline)

Further development of the PDC drill bit concept was the introduction in the later 1980s of Thermally Stable Polycrystalline (TSP) diamond bits. These bits are manufactured similarly to PDC bits but are tolerant of much higher temperatures than PDC bits.