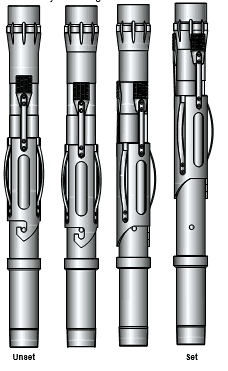

In a mechanical set liner hanger assembly, the setting mechanism is incorporated into the design of the liner hanger system, and its activation can be by reciprocation and rotation of the drill string at the surface. In most cases, the entire length of the casing liner below the hanger must be free to move to properly initiate the setting sequence. There are two basic types right-hand set and left-hand set.

Mechanical Set Liner Hanger Setting Procedures:

Generally, the setting sequence procedures of a mechanically set liner assembly is:

1. Position the liner at the desired setting depth ( Check also Casing setting depth article).

2. Raise the drill string (check our drill string design) sufficiently at the surface to align the jay pin in the upper trap in the jay slot of the slip cage.

3. Rotate the drill string sufficiently at the surface (1/4 turn at the hanger) to move the mechanical set liner hanger jay pin to setting position of the jay slot.

4. Lower the drill string until the cone contacts the slips, forcing them outward to engage the wall of the supporting casing ( Chech our casing design guide).

5. Continue to lower the drill string until the full liner weight is supported by the liner hanger

Liner Assemblies With Mechanical Setting Mechanisms

The primary advantage of a mechanical liner hanger is increased pressure integrity. Because these assemblies can be manufactured with an integral, one-piece body design, potential leakage is minimized by eliminating threaded cone connections. Unlike an internal hydraulic setting mechanism, mechanical liner assemblies do not rely on sustained integrity of the elastomer seal in potential high-pressure installations.

Mechanical liner assemblies can be manufactured with a single cone or with tandem cones, depending on the required Liner Hanger Hanging Capacity and the bypass area of the liner assembly when the slips are in the set position.

Main Applications Of Mechanical Set Liner Hanger

- Vertical or high angle holes. The liner assembly can incorporate a right-hand set option utilizing a spline or other means such as a jay slot in its design or it may be configured with a standard left-hand set option with a liner swivel that eliminates rotation of the liner below the liner hanger.

- Installations where the liner is hung prior to performing the cement job and maximum fluid bypass when the slips are in the set position is required.

- Deep well installations where maximum pressure integrity is required.

- Installations where the properties of a weighted mud system are not compatible for use with hydraulic setting mechanisms, or where heavy concentrations of loss circulation material are present.

- Mechanical set liner hanger Installations where liner reciprocation is required during mud conditioning and cementing operations. The premature setting of the liner due to the sudden occurrence of differential pressure is eliminated. The slips can be set and the liner hung after cementing operations are complete.

Additionally, mechanical set liner assemblies use varying jay slot designs in the setting mechanism. Although fairly simple in design and concept, specific jay slot designs provide unique operational features for the liner assembly.

Open Jay Slot Design

- Used on single cone liner hangers.

- Left or right-hand release options.

- Premature setting of the liner hanger during installation requires manipulation of the liner to reposition. An automatic re-jay option is available

- Debris and solids collected at the jay slot can be removed by circulating

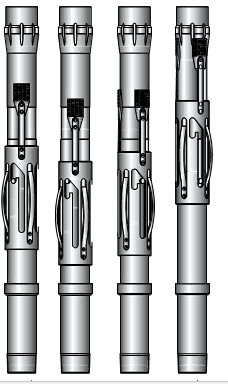

Enclosed Jay Slot Design

- Used on single or tandem cone liner hangers.

- Left or right-hand release options.

- The jay lug is enclosed and protected from deformation due to impact loading during installation.

- Slip travel is limited by the effective length of the jay slot. Overextension of the slips past the cone is eliminated.

Mechanical Set Liner Hanger In The Oilfield Market

Below we mention few examples of mechanical liner hanger in the oilfield market to deliver you the new technologies in mechanical liner hanger.

Frontier PermaFlex Mechanical Liner Hanger Technical Data Sheet

Frontier offers a Mechanical Set Liner Hanger called the Perma Flex Liner Hanger. They mentioned that it has Multiple Slip sets that will increase the liner hanging capacity. It also has a constrained Slips which will allow for drill string rotation while running the liner downhole without any damage to the cone.

NOV Mechanical Set Liner Hanger

NOV mentions in her website that its mechanical liner hanger can set in clockwise or counterclockwise. Also, it is set purely mechanically, with no need for hydraulic pressure. They also provide a paper that encourages drilling engineers to pick their liner hanger “Overcoming Challenges, Improving Understanding, and Optimizing Liner Deployment in Long Laterals”

Backer Hughes Mechanical Set liner

Back Hughes has a mechanical set liner hanger called CMC & Flex-Lock. Below the most important features of each of them

Flex-Lock Liner Hanger Applications:

- Highest load capacity

- Can anchor in both directions

- Wash/ream to bottom

- Locked up components available

- ISO rating V0

CMC mechanical set liner hanger Applications:

- High hanging capacities

- Economical mid-tier solution

- ISO Rating V3

- Medium Length Liner

Weatherford IntegraLine R high-Performance Rotational Hanger

Weatherford mentioned in their website that it is the first liner hanger tested and qualified to 15,000 psi (103 MPa) at 400°F (204°C). The design og the IntegraLine R hanger is applicable with deep and highly deviated wells, (high pressures and temperatures).