The term bentonite in drilling mud fluids was derived from the location of the first commercial deposit in the United States. In 1897, Knight reported that since 1888 William Taylor of Rock Creek, Wyoming, had been selling a “peculiar clay” found in the Fort Benton shale of Cretaceous age. Knight proposed the name “taylorite.” On learning that the term “taylorite” was already in use, Knight suggested “bentonite” for the “soft, greasy to 554 Drilling and Completion Fluids touch” clay that had been sold to eastern oil and gas companies for uses unknown. Only $810 had been paid for 150 tons shipped in 1897, a reduction from the original price of $25 per ton. Uses (reported later) had been as a component in toilet soap and, after leaching, as an adulterant in candy.

Characteristics Of Bentonite In Drilling Mud Fluids

Geologists concluded that bentonite was formed by the devitrification and chemical alteration of volcanic ash, and the mode of origin of the clay was included as part of the definition for this rock. Such a definition is inadequate because it excludes deposits of bentonite in many countries that did not originate from volcanic action.3 ‘ Thus, Grim and Niiven’s definition is preferred: “Any clay which is composed dominantly of a smectite clay mineral, and whose physical properties are dictated by this clay mineral.” Grim and Niven have described the worldwide geologic and geographic occurrence of bentonites, and have examined the variations in the mineral and chemical composition of the smectrites. Bentonite in drilling mud has also been defined as consisting of fine-grained clays that contain not less than 85% montmorillonite.

In mud parlance, bentonite is classified as sodium bentonite or calcium bentonite, depending on the dominant exchangeable cation. Correspondingly, in terms of performance, bentonite is classed as “high yield” and “low yield,” and in terms of geographic origin as “Western” and “Southern” because of the superior mud-making qualities of bentonite supplied from the Wyoming, South Dakota, and Montana deposits. This does not imply that these terms refer to distinct compositions.

Although Western bentonite in drilling mud is recognized as the highest quality clay for use in mud, the colloidal properties vary, even in the same deposit. Variations in properties within a deposit near Colony, Wyoming, as related to the thickness of the overburden, are shown in Fig. 1. The specific conductivity and the excess salts are highest at the weathered outcrop, as is the viscosity (yield) and gel development of the muds. The effect of drying temperature on the yield (bbl per ton of 15 cp mud) is also noticeable.

The heterogeneous nature of bentonite was shown by X-ray diffraction patterns and cation-exchange data for several samples of Wyoming bentonite separated into three fractions by centrifuging the suspensions. A correlation was observed between the plastic viscosity and gel strength properties of the mud as affected by the surface area and the exchangeable cation in centrifuged fractions. The relatively coarse fractions (least surface area) contained mainly calcium as exchangeable cation and showed distinctly lower viscosity and gel strength than the finer fractions in which sodium was dominant. These laboratory studies have been cited to show the necessity for bentonite in drilling mud suppliers to conduct adequate sampling of deposits; maintain large stockpiles; assure thorough mixing of the stockpiles, and carefully control drying, in order to produce a consistent product.

Mining and Processing.

The economic importance of bentonite in drilling mud has prompted state and federal geological surveys to publish numerous reports on its occurrence, its processing and its use. Only a sampling of these publications is cited here. The references listed in these papers and the more extensive reviews will provide additional sources of information.

After a potentially commercial bentonite deposit has been located, auger or core drills are used to collect samples for evaluation. If results are favorable, pits are laid out, with particular consideration given to quality and tonnage of recoverable bentonite, the ratio of required over-burden removal to recoverable bentonite, drainage, and reclamation.

Minable bentonite beds in drilling mud vary in thickness from a minimum of two feet. The maximum stripping depth is about sixty feet. After the overburden has been removed, the bed may be resampled on closer spacing. Based on test results, the pit is marked for selective mining.

A common practice is to expose the clay to air for several months, during which time the bed may be plowed or ripped. This practice promotes drying and improves the quality of the clay.

The bentonite in drilling mud areas of differing quality are mined separately and hauled to stockpiles located at the processing plant. From the stockpiles, the selected bentonite is passed through a slicer or cutter for sizing, and then into a dryer where the moisture content is reduced from 15-35% to 8-10%. The dried bentonite is ground in roller mills. Based on the results of performance tests on samples of the clay, small amounts of polyacrylates (maximum of 2 Ib/ton) may be added to the mill feed. Cyclone collectors extract the minus200-mesh product, which is transferred to storage in silos pending bagging or loading into hopper cars.

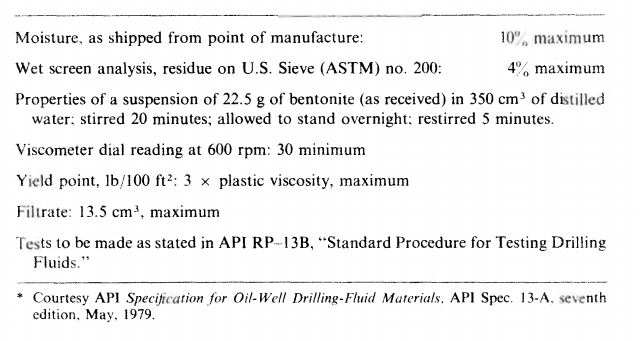

Bentonite furnished to API specifications must satisfy the requirements listed in Table 1.

Bentonite in Drilling Mud Applications

Bentonite is added to freshwater or to freshwater muds for one or more of the following purposes:

- Firstly, to increase hole cleaning capability;

- Secondly, to reduce water seepage or filtration into permeable formations;

- Thirdly, to form a thin filter cake of low permeability;

- Fourthly, to promote hole stability in poorly cemented formations, and

- Fifthly, to avoid or overcome the loss of circulation.

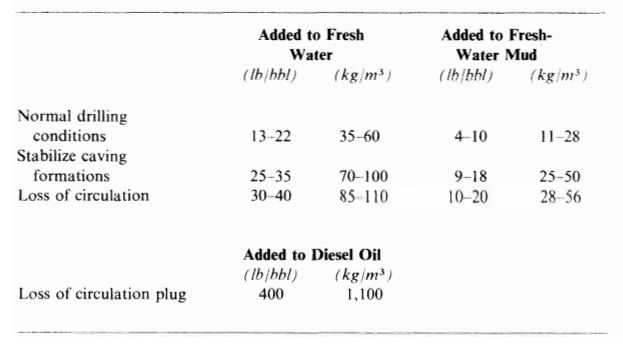

The amount to be added will, of course, vary with specific conditions but approximate quantities are suggested in Table 2.

Bentonite continues to rank second in quantity only to barite as a mud additive, as shown in Fig. 11-2.14 In spite of the partial replacement of bentonite by polymers in some muds, about 1,160,000 short tons (1,050,000 tonnes) of swelling-type bentonite, with a well-site cost of roughly $120,000,000 (check also oil well drilling well cost per foot), was used in 1978.

Southern Bentonite

Bentonite in which calcium predominates as the exchangeable cation is mined in Texas, Mississippi, Alabama, Oklahoma and Louisiana.30 As much as 30,000 to 40,000 tons per year of bentonite mined in Texas is treated with sodium carbonate and polyacrylates to meet API specifications. About an equal quantity of Southern bentonite treated with sodium carbonate is sold as “drilling clay” and is largely used only in drilling operations near the source of the clay.

Beneficiated, Super-Yield Bentonite

Terms such as peptized, beneficiated, and extra-high yield describe bentonites to which organic polymers (and sometimes also soda ash) have been added during processing. These products made with Western bentonite are useful as starting or spud muds, in low solids muds, and in applications where the cost of transportation is extremely high. Less than half as much of such a material is needed compared to the amount of API-specification bentonite.

Patents have been granted on numerous compositions, among which those cited here are representative, for increasing the thickening effect. Typically, the polymer is derived from acrylic acid and the like. The selected polymer is blended with the dried bentonite before milling. The quantity of polymer added varies with the type of polymer and with its effect on the specific bentonite but is usually between 0.1% and 2% of the weight of the bentonite. Somewhat higher concentrations of the polymer may have no beneficial effect or may even be objectionable because the polymer then behaves as a flocculant.

Bentonite-polymer compositions containing about 20% to 30% by weight of partial calcium salt of sodium polyacrylate, or a mixture of both, are reported to have a yield of more than 500 bbl of 15-cp mud per ton, with satisfactory filtration properties.

Because the available bentonite has been declining in quality in recent years, it has become necessary to add extenders to almost all bentonites in order to meet API specifications. Bol reports that such bentonites may give an unsatisfactory performance under certain field conditions, such as high temperature, presence of bivalent cations in seawater, and the adding of the bentonite to cement. In extensive tests, he found that the performance of the different brands of bentonite varied widely and that these differences were due to the extending polymer. He concluded that the API tests should be revised to take into account the effect of the polymer used.

Prehydrated Bentonite in Salt-Water Muds

Before Attapulgus clay (fuller’s earth) came into use as a thickener for saltwater, bentonite was mixed into fresh water and allowed to swell for a while. Then, the thick slurry was diluted with saltwater. This prehydrated bentonite provides only temporary suspension properties and very little filtration control.

Some improvement in performance was achieved by adding caustic soda and quebracho to the freshwater along with the bentonite. Much greater stability in the salty environment, and lower filtration, is obtained by adding ferrochrome lignosulfonate to the fresh-water bentonite, 3 Ib/bbl (9 kg/m3 ) of ferrochrome lignosulfonate, and 0.5 Ib/bbl (1.5 kg/m3 ) of caustic soda in freshwater.

The addition of a vinyl acetate-maleic acid polymer to an aged 5%-by weight suspension of bentonite in freshwater has been recommended as a slurry to be diluted with salt water. Flax meal added to the premix improves filtration control.

References

- Fourth edition. Lefond, S.J., ed. AIME, New York, 1975. pp. 519-585.

- Knight, W.C., “Mineral Soap,” Eng. Min. J., vol. 63 (1897). pp. 600, 601.

- Knight, W.C., “Bentonite,” Eng. Min. J., vol. 66 (1898). p. 491.

- Ibid., p. 638.

- Hewitt, D.F., “The Origin of Bentonite,” J. Wash, Acad. 5V/., vol. 7 (1917). pp. 196-198.

- Wherry, E.T., “Clay Derived from Volcanic Dust in the Pierre of South Dakota,” J. Wash. Acad. Sci., vol. 7 (1917). pp. 576-583.

- Ross, C.S., and Shannon, E.V., “The Minerals of Bentonite in drilling mud and Related Clays and Their Physical Properties,” J. Amer. Ceramic. Soc., vol. 9, no. 2 (1929), pp. 77-96.

- Grim, R.E. and Niiven, N., Bentonites: Geology, Mineralogy, Properties and Uses, vol. 24. From the series, Developments in Sedimentology. Elsevier Scientific Publishing Co., Amsterdam, 1978.

- Williams, F.J., Neznayko, M., and Weintritt, D.J., “The Effect of Exchangeable Bases on the Colloidal Properties of Bentonite.”J. Phys. Chem., vol. 57 (1953). pp. 6-10.

- Williams, F.J., Elsley, B.C., and Weintritt, D.J., “The Variations of Wyoming Bentonite Beds as a Function of the Overburden,” Clays, Clay Minerals, vol. 2 (1953). pp. 141-151.

- McAtee, J.L., Jr., “Heterogeneity in Montmorillonite,” Clays, Clay Minerals, vol. 5 (1956). pp. 279-288.

- Jessen, F.W., and Mungan, N., “The Effect of Particle Size Distribution and Exchange Cation on Gel Properties of Fractionated Bentonite Suspensions,” Trans. AIME, vol. 216 (1959). pp. 455-459.

- Davis, C.W., Vacher, H.C., and Conley, I.E., “Bentonite in drilling mud, Its Properties, Mining, Preparation and Utilization,” U.S. Bureau of Mines. Tech. Pub. 609 (1940).

- Knechtel, M.M., and Patterson, S.H., “Bentonite Deposits in Marine Cretaceous Formations, Hardin District, Montana and Wyoming,” U.S. Geol.

Survey Bull. 1023 (1956).

Drilling Fluids Components 605 - Knechtel, M.M., and Patterson, S.H., “Bentonite Deposits of the Northern Black Hills District, Wyoming, Montana, and South Dakota,” U.S. Geol. Survey Bull. 1082-M (1962). pp. 893-1030.

- Maple, W.J., and Pillmore, C.L., “Geology of the Inyan Kara Mountain Quadrangle, Crook and Western Counties, Wyoming,” U.S. Geol. Survey Bull 1121-M (1963).

- Maple, W.J., and Pillmore, C.L., “Geology of the Newcastle Area, Western County, Wyoming,” U.S. Geol. Survey Bull. 1141-N (1963).

- Berg, R.B., “Bentonite in Montana,” Montana Bureau Mines and Geol., Bull. 74 (1969).

- Wayland, T.E., “Geologic Occurrence and Evaluation of Bentonite Deposits,” Trans. AIME, vol. 250 (1971). pp. 120-133.

- Lindsey, B.J., “Conditioning of Drilling Fluids,” U.S. Patent No. 2,320,622 (June 1, 1943).

- Dawson, L.R., “Well Drilling Muds and Improved Compositions for Producing Same,” U.S. Patent No. 2,702,788 (Feb. 22, 1955).

- Morgan, R.L., “Drilling Muds Containing Acrylic and Acrylamide Copolymer Salts,” U.S. Patent No. 2,775,557 (Dec. 25, 1956).

- Scott, P.P.. “Low Solids Drilling Fluid,” U.S. Patent No. 3,070,543 (Dec. 25, 1962).

- Turner, F., and Dillon, E.T., “Beneficiated Clay Bentonite Compositions and Method of Beneficiating Clay,” for drilling mud U.S. Patent No. 2,948,678 (Aug. 9, 1960).

- Jackson, W.R., and Oakes, D.T., “Clay Beneficiation,” U.S. Patent No. 3,070,544 (Dec. 25, 1962).

- Reinhard, R.H., “Clay Beneficiation,” U.S. Patent No. 3,216,934 (Nov. 9, 1965).

- Turner, F., “Beneficiated Clay Composition for Use In Drilling Fluid,” U.S. Patent No. 3,220,946 (Nov. 30, 1965).

- Lummus, J., “Low Solids Drill. Fluid,” U.S. Patent 3,558,545 (Jan. 26, 1971).

- Lang, W.J., “Acrylic Acid—Methyl Cellulose Graft Copolymers for Treating Sub-Bentonitic Clay,” U.S. Patent No. 3,583,911 (June 8, 1971).

- Lang, W.J., and Krajewski, J.J., “Graft Copolymers of Acrylic Acid and Polyhydroxy Polymeric Compounds for Treating Clays,” U.S. Patent No. 3,640,826 (Feb. 8, 1972).

- Lang, W.J., “High Yield Bentonites in drilling mud,” U.S. Patent No. 3,687,846 (Aug. 29, 1.972).

- Le Blanc, J.R., “Beneficiating Agents,” U.S. Patent No. 3,816,308 (June 11, 1974).

- Le Blanc, J.R., “Process for Improving the Yield of Clay and Drilling Muds Prepared Therefrom,” U.S. Patent No. 3,838,047 (Sept. 24, 1974).

- Clem, A.G., “Super-Yield Bentonite Base Drilling Fluid mud,” U.S. Patent No.

4,087,365 (May 2, 1978). - Bol, G. M., “Bentonite Quality and Quality Evaluation Methods,” SPE/IADC paper #13454, Drilling Conference, New Orleans, March 5-8, 1985; and SPEDrill. Eng. (Aug. 1985). pp. 288-296.

- Cross, R., and Cross, M.F., “Aqueous Suspension Compositions,” U.S. Patent No. 2,044,758 (June 16, 1936).

- Mondshine, T.C., and Kercheville, J.D., “A New Salt Mud from Q-Broxin and Aquagel,” Baroid News Bull., vol. 15, no. 3 (1963). pp. 12-17.

- Anderson, D.B., and Lummus, J.L., “Low S