When the mud is in a static condition, the rheological properties should prevent solids (weighting material and drilled formation solids) from settling. The relevant property in this respect is the mud’s gel strength. The drilling mud gel strength is caused by the interactive forces between colloids (e.g., clay particles), polymer radicals, or emulsion droplets in mud, which form a more or less rigid structure (gel). The gel strength, being the force required to initiate movement in a gelled fluid, is measured with a FANN rotational viscometer (Check viscometer test procedure).

How Does Gel Strength Occur In Drilling Mud?

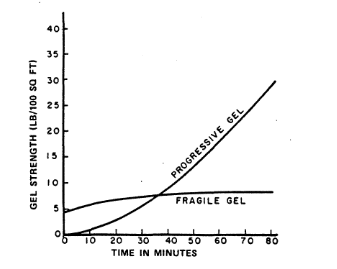

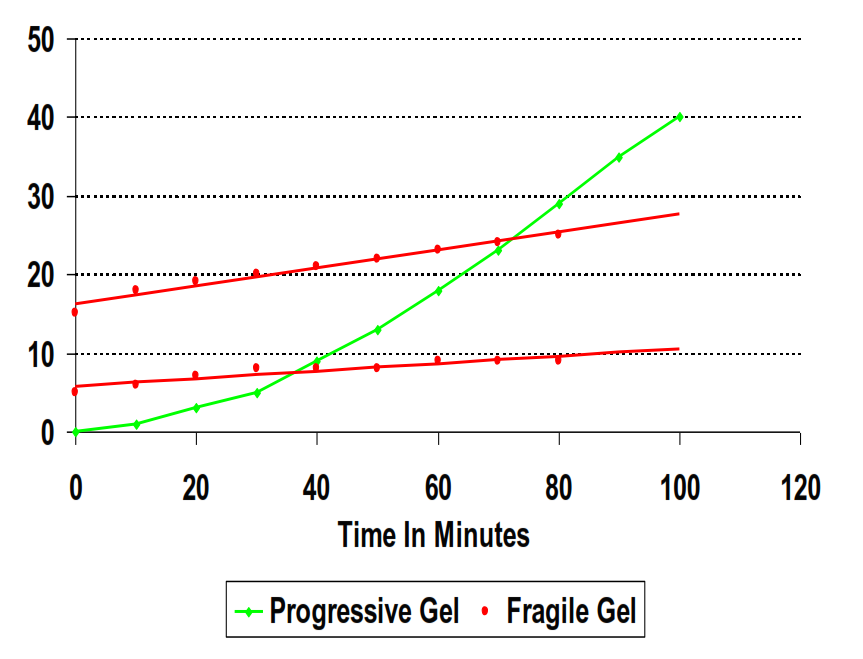

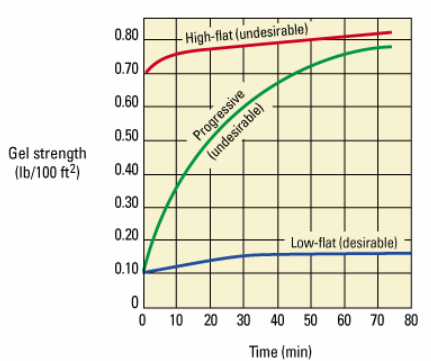

It arises mainly from the attraction between particles and friction between solids in suspension. Gels may be progressive or fragile. Progressive gels increase continuously for an extended period of time. This increase may create problems during tripping (surge/swab pressures) and when resuming circulation. Fragile or “flat” gels reach a near-maximum in a brief time interval. You might also be interested in the yield stress of drilling mud.

Progressive Gel Strength

Usually, it increases with time in a stagnant drilling mud (“progressive” gels), which is reflected in the difference between the “zero” and “ten minutes” gel values (measuring gels subsequently after ten seconds and ten minutes is a standard procedure). Some progressiveness in gel values is required to prevent solids from settling during long stagnant periods.

The level and progressiveness of the gel strength values depend on the concentration and type of interacting particles. The concentration of the particles mainly determines the initial gel strength. In contrast, the ten-minute gel is primarily governed by the rigidity of the interparticle structure formed. In clay-based muds, the interparticle structures can be strong, reflected in progressive gel development in those muds. On the other hand, the bonds between polymers are relatively weak, which results in “flat” gels in polymer muds (flat gel).

In IOEM, the gels are primarily provided by the emulsion droplets. The concentration of these droplets is high, which explains the characteristic high initial gel strength of IOEM. In addition to that, the presence of clays that have undergone treatment with a surfactant to make them oil-dispersible is mainly responsible for the increased 10-minute gel in these muds.

In conclusion, Progressive gel may be an indication of the following:

- Solids Crowding

- The concentration of Reactive Solids is too high.

- Carbonate Contamination

Note: Decreasing Gel strength is one of the measures to avoid Lost Circulation Problems.

Gel Strength Values In Drilling Mud

Typical values that should be aimed for are:

| Item | 10’’ gel (lbs/100 ft2) | 10’ gel (lbs/100 ft2) |

| For weighted polymer muds, | 2- 5 | 5-10 |

| For weighted clay-based muds | 4- 8 | 8-20 |

| For unweighted polymer muds (KC1-polymer, salt-saturated mud) | 1- 2 | 3- 5 |

| For weighted polymer muds | 2- 5 | 6-10 |

| For unweighted IOEM (OWR 75/25) | 5-10 | 8-15 |

| For weighted IOEM (OWR 75/25) | 10-15 | 15-25 |

Gel values are typically expressed in field units. Conversion into 51 units (Pa) can be established by multiplying the above values with 0.479.

Gel values should not be too high or too progressive, as this could cause problems during the following operations:

- When restarting the mud pump and circulating after a prolonged stagnant period (e.g., a round trip). The force (pump pressure) required to break the gel structure might exceed the formation fracturing pressure and induce losses;

- During movement of pipe (up or down) in a stagnant fluid, while tripping pipe, pressure surges might induce losses or influxes from formation fluids (Surging & Swapping in Drilling);

- A high gel strength hampers the removal of solids and entrapped gases at the surface.

It is, therefore, essential to aim for the above gel values, particularly in areas with a known low formation strength or in case of a general small overbalance.

Generally, a 10-minute gel of 30-35 Ibs/100 ft2 should be considered a maximum for all muds at all conditions. Higher gels with excessive gel strength also should be avoided or be reduced by remedial mud treatment (thinning or dilution)

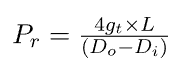

Application of Pressure To Gelled Mud

If the mud is left to stand, a gel will be formed due to its inherent thixotropy, and a definite pressure must then be applied to break up the gel and restore the fluidity of the mud. If the gel strength (long-time) as determined in the Fann viscometer is g, the pressure that must be applied to restore the circulation of the mud can be found by the equation.

Where:

- gt = long-time gel strength (gt more than or equal to g10)

- L = section length

- Do = hole diameter

- Di = external diameter of string

- Pr = pressure

However, the gel strength determined at the surface may be partially representative of the effective obe in the hole, especially if the gelation of the mud takes place under the influence of heat.

Moving the mud following a stagnant period (e.g., moving the drill string or starting the pump) should not produce a dangerous overpressure. If possible, the gel should be broken up by rotating the string before starting mud circulation.

Gel Strength Measurement & Calculations

In general, its measurements are made with the V-G meter and describe the time-dependent flow behavior of a drilling fluid. These values must be recorded at 10-second (initial gel) and 10-minute intervals. One additional value should be recorded at 30 minutes. The following instruments are used for such measurements:

- Firstly, Marsh funnel – a simple device for indication of viscosity and gel strength on a routine basis,

- Secondly, a Direct-indicating viscometer – a mechanical device for measurement of viscosity at varying shear rates.

- Shearometer: used to obtain information concerning shear strength.

The Values Of 10 Secs & 10 Mins Gels

Indications of rheological problems in a mud system are often reflected by the development of a mud’s gel strength over time.

- If there is a large discrepancy between the initial and 10-minute gel readings, this is known as “progressive gels,” which is an undesirable situation.

- Similarly, if both initial and 10-minute gels are high, with no significant difference, they are called “high-flat gels,” which is also undesirable.

The degree of gelation over time is a crucial factor in the performance of a drilling fluid. Gelation should not be allowed to become much higher than necessary to suspend cuttings and weight material effectively. As illustrated in the figure, “low-flat gels” are preferred for suspension.

The mud in the excessive gel may cause the following problems:

- Retaining entrapped air, gas, sand, and cuttings inside the drilling fluids.

- Performing logging with wireline tools will be more difficult.

- Swabbing and surging problems while tripping.

Conclusion

This one of the drilling fluid’s properties depends on various factors such as chemical treatment, solids concentration, time, and temperature. There is no established formula for predicting gel strength in any fluid system. It generally increases with time, temperature, and the amount of solids present. If the fluid system isn’t adequately treated for temperature stability, the gel strength developed after a drilling bit trip becomes a major factor in the pressure required to break circulation and in the magnitude of swab and surge pressures.

Additionally, in a weighted fluid system, the initial gel strength must be sufficient to prevent the settling of weight materials. Therefore, the mud engineer must ensure sufficient initial gel but not excessive long-term gel. Gel strengths are crucial for suspension properties under static conditions and when performing swab and surge analysis.

When running a Drill String or casing pipe into the hole, it is necessary to overcome the gel. Gel strengths also affect the ability of a fluid to release entrained gases. While running into the hole, it may be necessary to intermittently break circulation instead of initiating flow throughout the entire wellbore to reduce pressure spikes and facilitate circulation initiation.

References:

- Ryen Caenn, 2011. Composition and Properties of Drilling and Completion Fluids, Sixth Edition. 6 Edition. Gulf Professional Publishing.

- Chevron Drilling Mud Manual

How to calculate the Hi viscosity pills in the well and out of the well?

How many bbls are pumped insides in the well and out of the well?

Accuracy, we’ll need the calculations of the bbls pumped insides the well and out of the well.

2.Mud losses calculation.