API Drill Pipe Specifications (specs) are generally described as six items. For example, a 5″ drill pipe is 5″, #19.5, E, XH, NC50, Premium. Now let’s understand what are the main items that describe any DP :

- Tube OD

- Nominal weight

- Pipe grade

- Type of tool joint.

- API drill pipe thread connection types.

- Drill pipe classification.

| 5” | 19.5 | Grade ”E” | XH | NC50 | Premium |

| tube OD | Nominal Weight | Minimum Yield strength | Upset Tool Joint | Connection thread | Drill Pipe Classification (wear) |

Each description item is explained in more detail below.

Lengths

In general, joints are available in three drill pipe length ranges. These ranges differ from the length ranges of the Casing Pipes we previously discussed.

| Range | Length, ft |

| 1 | 18-22 |

| 2 ( is the most common) | 27-30 |

| 3 | 38-45 |

Drill Pipe Size or OD Specifications (SPECs)

The OD is simply the plain end (tube) outside diameter. These drill pipes are available in various sizes. Common sizes include 2 3/8 inch, 5 inch, 5 1/2, and 6 5/8 inch.

Drill Pipe Nominal Weight Specifications (SPECs)

Generally, When referring to Drill Pipe Weights, there are four important ones:

- Plain end Weight– Refers to the weight per foot of the pipe body.

- Nominal Weight- Refers to an obsolete standard. ( Weight of Range I pipe with connections ). It is used today to refer to a pipe class.

- Adjusted Weight– Refers to the weight per foot of pipe, including the upset but excluding the tool joint, based on a length of 29.4 ft.

- Approximate Weight– The average weight per foot of pipe and Range II pipe tool joints. This approximate weight is the number to use in Design calculations.

The D/P nominal weight is the weight per foot, including the weight of an API regular connection. The number serves no real purpose other than identification because the drill pipe does not have a regular API connection.

So, the actual weight depends on the type of connection thread and pipe grade. As the grade (minimum yield strength) increases, the actual weight increases because the upset has more metal.

The actual weight of the 5” D/P in the above example is 20.89 lb/ft. The actual weight for grade G pipe is 21.92 lb/ft.

The Drill Pipe Grade Specifications

The pipe Grade states the minimum yield strength of the metal, which is the tensile stress that will result in 0.5% strain. Grade E D/P has a yield strength of 75,000 psi.

The minimum strength can be converted to a more usable strength in pounds by multiplying the minimum yield in psi by the cross-sectional area of the metal.

| API Drill Pipe Grade | Minimum Yield Strength (psi) | Minimum Tensile Strength (psi) |

| E-75 | 75,000 | 100,000 |

| X-95 | 95,000 | 105,000 |

| G-105 | 105,000 | 115,000 |

| S-135 | 135,000 | 145,000 |

The Tool Joint

A drill pipe tool joint is a heavy coupling element with tapered threads and seating shoulders designed to suspend the weight of the whole string, withstand frequent makeup and breakout, and provide a leakproof seal. It consists of a pin and a box, welded during manufacture.

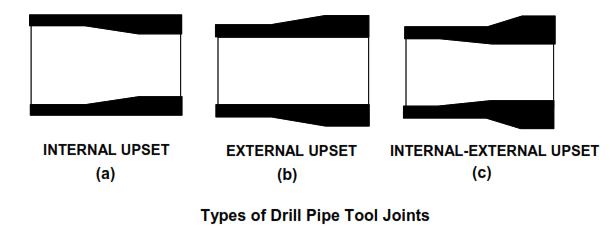

Type Of Tool Joint Upset

Tool joint upset type is a part of the API drill pipe specifications (specs). Tool joints are mainly screw-type connectors that join the individual joints of D/P. Also, each pipe joint is fitted with a pin (male thread) and box (female thread) tool joints or connectors.

API Upset Types

- IEU (Internal-External Upset) – The tool joint OD is larger than the OD of the drill pipe, and the tool joint ID is less than the pipe body ID. Generally, IEU tool joints are the strongest available. So, the tool joint’s large OD and small ID cause relatively high external and internal pressure losses.

- IF (External Upset) – The tool joint ID is the same as the ID of the D/P to minimize internal pressure losses. The upset is on the OD of the tool joint.

- IU (Internal Upset) – The tool joint ID is less than that of the D/P. So, the small ID causes relatively higher internal pressure losses. The tool joint OD is the same as the OD of the pipe body. This type is called a slim-hole drill pipe because of the small OD.

Classification (Wear)

As the new drill pipe is rotated in the hole, it wears and, therefore, it must be reclassified according to its wear. Exterior wear includes OD wear, dents and mashes, slip area crushing, cuts, pitting, and corrosion. The working strength is reduced because of loss in cross-sectional area.

The D/P is inspected periodically to detect cracks, pits, reduction in wall thickness, and other defects. Inspection methods include electromagnetic inspection of pipe body to locate cracks and pits, sonic inspection to measure wall thickness, visual inspection to detect mashes and caliper measurements.

The API has established guidelines for drill pipe classification classes in API RP7G. The classes are summarized as follows:

| New: | No wear and has never been used. |

| Premium: | Uniform wear and a minimum thickness of 80% of the original wall thickness. |

| Class 2: | Allows D/P with a minimum wall thickness of 65% with all wear on one side so long as the cross-sectional area is the same as premium class, that is to say, based on not more than 20% uniform wall reduction. |

| Class 3: | Allows drill pipe with a minimum wall thickness of 55% with all wear on one side. |

2 3/8″ Drill Pipe Specifications

| Pipe Data | Tool Joint Data | Assembly Data | ||||||||||||||||||||||||

| Size Outer D | Nominal Weight | Grade and UpsetType | Torsional Yield Strength | Tensile Yield Strength | Wall Thickness | Nominal ID | Pipe Body Section Area | Pipe Body Section Modulus | Pipe Body Polar Section Modulus | Internal Pressure | Collapse Pressure | Connection Type | Outside Diameter | Inside Diameter | Torsional Yield Strength2 | Tensile Yield Strength3 | Make-up Torque | Torsional Ratio Tool Joint to Pipe | * Pin Tong Space | * Box Tong Space | Adjusted Weight | Minimum Tool Joint O.D. for Prem. Class | Drift Diameter | Capacity | Displace- ment | Size Outer D. |

| 2 3/8 | 6.65 | E-75 EU | 6,300 | 138,200 | 0.280 | 1.815 | 1.843 | 0.867 | 1.733 | 15,474 | 15,599 | NC26 | 3 3/8 | 1 3/4 | 6,900 | 313,700 | 3,900 | 1.10 | 9 | 10 | 7.17 | 3 3/16 | 1 5/8 | 0.134 | 0.110 | 2 3/8 |

| HT26 | 3 3/8 | 1 3/4 | 8,700 | 313,700 | 5,200 | 1.38 | 9 | 12 | 7.25 | NA | 1 5/8 | 0.134 | 0.111 | 2 3/8 | ||||||||||||

| SLH90 | 3 1/4 | 1 13/16 | 6,900 | 270,200 | 3,700 | 1.10 | 9 | 10 | 7.00 | 3 1/32 | 1 11/16 | 0.134 | 0.107 | 2 3/8 | ||||||||||||

| 2 3/8 | 6.65 | X-95 EU | 7,900 | 175,100 | 0.280 | 1.815 | 1.843 | 0.867 | 1.733 | 19,600 | 19,759 | NC26 | 3 3/8 | 1 3/4 | 6,900 | 313,700 | 3,900 | 0.87 | 9 | 10 | 7.17 | 3 1/4 | 1 5/8 | 0.134 | 0.110 | 2 3/8 |

| HT26 | 3 3/8 | 1 3/4 | 8,700 | 313,700 | 5,200 | 1.10 | 9 | 12 | 7.25 | NA | 1 5/8 | 0.134 | 0.111 | 2 3/8 | ||||||||||||

| SLH90 | 3 1/4 | 1 13/16 | 6,900 | 270,200 | 3,700 | 0.87 | 9 | 10 | 7.00 | 3 3/32 | 1 11/16 | 0.134 | 0.107 | 2 3/8 | ||||||||||||

| 2 3/8 | 6.65 | G-105 EU | 8,800 | 193,500 | 0.280 | 1.815 | 1.843 | 0.867 | 1.733 | 21,663 | 21,839 | NC26 | 3 3/8 | 1 3/4 | 6,900 | 313,700 | 3,900 | 0.78 | 9 | 10 | 7.17 | 3 9/32 | 1 5/8 | 0.134 | 0.110 | 2 3/8 |

| HT26 | 3 3/8 | 1 3/4 | 8,700 | 313,700 | 5,200 | 0.99 | 9 | 12 | 7.25 | NA | 1 5/8 | 0.134 | 0.111 | 2 3/8 | ||||||||||||

| SLH90 | 3 1/4 | 1 13/16 | 6,900 | 270,200 | 3,700 | 0.78 | 9 | 10 | 7.00 | 3 1/8 | 1 11/16 | 0.134 | 0.107 | 2 3/8 | ||||||||||||

| 2 3/8 | 6.65 | S-135 EU | 11,300 | 248,800 | 0.280 | 1.815 | 1.843 | 0.867 | 1.733 | 27,853 | 28,079 | NC26 | 3 5/8 | 1 1/2 | 9,000 | 390,300 | 4,900 | 0.80 | 9 | 10 | 7.62 | 3 13/32 | 1 3/8 | 0.132 | 0.117 | 2 3/8 |

| HT26 | 3 3/8 | 1 5/8 | 9,500 | 353,400 | 5,700 | 0.84 | 9 | 12 | 7.35 | NA | 1 1/2 | 0.133 | 0.112 | 2 3/8 | ||||||||||||

| SLH90 | 3 1/4 | 1 11/16 | 7,700 | 311,500 | 4,200 | 0.68 | 9 | 10 | 7.10 | 3 7/32 | 1 9/16 | 0.133 | 0.109 | 2 3/8 | ||||||||||||

| GPDS26 | 3 1/2 | 1 11/16 | 9,700 | 333,900 | 5,800 | 0.86 | 9 | 10 | 7.35 | 3 5/16 | 1 9/16 | 0.133 | 0.112 | 2 3/8 | ||||||||||||

| 2 3/8 | 6.65 | Z-140 EU | 11,700 | 258,000 | 0.280 | 1.815 | 1.843 | 0.867 | 1.733 | 28,884 | 29,119 | XT24 | 3 1/8 | 1 1/2 | 9,500 | 261,500 | 5,700 | 0.81 | 10 | 15 | 7.32 | 2 15/16 | 1 3/8 | 0.131 | 0.112 | 2 3/8 |

| XT26 | 3 3/8 | 1 5/8 | 12,600 | 330,600 | 7,600 | 1.08 | 10 | 15 | 7.52 | 3 1/32 | 1 1/2 | 0.132 | 0.115 | 2 3/8 | ||||||||||||

| HT26 | 3 3/8 | 1 5/8 | 9,500 | 353,400 | 5,700 | 0.81 | 9 | 12 | 7.35 | NA | 1 1/2 | 0.133 | 0.112 | 2 3/8 | ||||||||||||

| GPDS26 | 3 1/2 | 1 5/8 | 10,500 | 353,400 | 6,300 | 0.90 | 9 | 10 | 7.39 | 3 5/16 | 1 1/2 | 0.133 | 0.113 | 2 3/8 | ||||||||||||

| 2 3/8 | 6.65 | V-150 EU | 12,500 | 276,400 | 0.280 | 1.815 | 1.843 | 0.867 | 1.733 | 30,947 | 31,199 | XT24 | 3 1/8 | 1 3/8 | 10,400 | 295,400 | 6,200 | 0.83 | 10 | 15 | 7.41 | 2 15/16 | 1 1/4 | 0.130 | 0.113 | 2 3/8 |

| XT26 | 3 3/8 | 1 1/2 | 13,200 | 367,400 | 7,900 | 1.06 | 10 | 15 | 7.62 | 3 | 1 3/8 | 0.131 | 0.117 | 2 3/8 | ||||||||||||

| HT26 | 3 3/8 | 1 1/2 | 10,100 | 390,300 | 6,100 | 0.81 | 9 | 12 | 7.45 | NA | 1 3/8 | 0.131 | 0.114 | 2 3/8 | ||||||||||||

| GPDS26 | 3 1/2 | 1 1/2 | 11,200 | 390,300 | 6,700 | 0.90 | 9 | 10 | 7.48 | 3 9/32 | 1 3/8 | 0.132 | 0.114 | 2 3/8 | ||||||||||||

2 7/8″ API Drill Pipe Specs

| Pipe Data | Tool Joint Data | Assembly Data | ||||||||||||||||||||||||

| Size Outer D | Nominal Weight | Grade and Upset Type | Torsional Yield Strength | Tensile Yield Strength | Wall Thickness | Nominal ID | Pipe Body Section Area | Pipe Body Section Modulus | Pipe Body Polar Section Modulus | Internal Pressure | Collapse Pressure | Connection Type | Outside Diameter | Inside Diameter | Torsional Yield Strength | Tensile Yield Strength | Make-up Torque | Torsional Ratio Tool Joint to Pipe | * Pin Tong Space | * Box Tong Space | Adjusted Weight | Minimum Tool Joint O.D. for Prem. Class | Drift Diameter | Capacity | Displace- ment | Size Outer D |

| 2 7/8 | 6.65 | E-75 IU | 8,100 | 135,900 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 9,907 | 10,467 | XT26 | 3 3/8 | 1 3/4 | 11,500 | 290,900 | 6,900 | 1.42 | 10 | 15 | 7.43 | 2 29/32 | 1 5/8 | 0.234 | 0.114 | 2 7/8 |

| G-105 IU | 11,300 | 190,300 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 13,869 | 14,020 | XT26 | 3 3/8 | 1 3/4 | 11,500 | 290,900 | 6,900 | 1.02 | 10 | 15 | 7.43 | 3 1/16 | 1 5/8 | 0.234 | 0.114 | 2 7/8 | ||

| S-135 IU | 14,500 | 244,600 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 17,832 | 17,034 | XT26 | 3 3/8 | 1 3/4 | 11,500 | 290,900 | 6,900 | 0.79 | 10 | 15 | 7.43 | 3 7/32 | 1 5/8 | 0.234 | 0.114 | 2 7/8 | ||

| V-150 IU | 16,200 | 271,800 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 19,813 | 18,398 | XT26 | 3 3/8 | 1 3/4 | 11,500 | 290,900 | 6,900 | 0.71 | 10 | 15 | 7.43 | 3 9/32 | 1 5/8 | 0.234 | 0.114 | 2 7/8 | ||

| X-95 IU | 10,200 | 172,100 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 12,548 | 12,940 | XT26 | 3 3/8 | 1 3/4 | 11,500 | 290,900 | 6,900 | 1.13 | 10 | 15 | 7.43 | 3 1/32 | 1 5/8 | 0.234 | 0.114 | 2 7/8 | ||

| Z-140 IU | 15,100 | 253,700 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 18,492 | 17,500 | XT26 | 3 3/8 | 1 3/4 | 11,500 | 290,900 | 6,900 | 0.76 | 10 | 15 | 7.43 | 3 1/4 | 1 5/8 | 0.234 | 0.114 | 2 7/8 | ||

| 2 7/8 | 6.85 | E-75 EU | 8,100 | 135,900 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 9,907 | 10,467 | NC31 | 4 1/8 | 2 5/32 | 11,500 | 434,500 | 6,200 | 1.42 | 9 | 11 | 7.88 | 3 11/16 | 2 1/32 | 0.239 | 0.120 | 2 7/8 |

| 8,100 | 135,900 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 9,907 | 10,467 | HT31 | 4 | 2 5/32 | 14,900 | 434,500 | 8,900 | 1.84 | 9 | 13 | 7.83 | 3 1/2 | 2 1/32 | 0.239 | 0.120 | 2 7/8 | |||

| 8,100 | 135,900 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 9,907 | 10,467 | XT31 | 4 | 2 3/8 | 13,200 | 309,100 | 7,900 | 1.63 | 10 | 15 | 7.75 | 3 13/32 | 2 1/4 | 0.242 | 0.118 | 2 7/8 | |||

| E-75 IU | 8,100 | 135,900 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 9,907 | 10,467 | NC26 | 3 3/8 | 1 3/4 | 6,900 | 313,700 | 3,900 | 0.85 | 9 | 10 | 7.19 | 3 9/32 | 1 5/8 | 0.236 | 0.110 | 2 7/8 | ||

| 8,100 | 135,900 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 9,907 | 10,467 | HT26 | 3 3/8 | 1 3/4 | 8,700 | 313,700 | 5,200 | 1.07 | 9 | 12 | 7.27 | NA | 1 5/8 | 0.235 | 0.111 | 2 7/8 | |||

| G-105 EU | 11,300 | 190,300 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 13,869 | 14,020 | NC31 | 4 1/8 | 2 5/32 | 11,500 | 434,500 | 6,200 | 1.02 | 9 | 11 | 7.88 | 3 13/16 | 2 1/32 | 0.239 | 0.120 | 2 7/8 | ||

| 11,300 | 190,300 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 13,869 | 14,020 | HT31 | 4 | 2 5/32 | 14,900 | 434,500 | 8,900 | 1.32 | 9 | 13 | 7.83 | 3 5/8 | 2 1/32 | 0.239 | 0.120 | 2 7/8 | |||

| 11,300 | 190,300 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 13,869 | 14,020 | XT31 | 4 | 2 3/8 | 13,200 | 309,100 | 7,900 | 1.17 | 10 | 15 | 7.75 | 3 17/32 | 2 1/4 | 0.242 | 0.118 | 2 7/8 | |||

| G-105 IU | 11,300 | 190,300 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 13,869 | 14,020 | NC26 | 3 5/8 | 1 3/4 | 7,200 | 313,700 | 3,900 | 0.64 | 9 | 10 | 7.46 | 3 13/32 | 1 5/8 | 0.236 | 0.114 | 2 7/8 | ||

| 11,300 | 190,300 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 13,869 | 14,020 | HT26 | 3 3/8 | 1 3/4 | 8,700 | 313,700 | 5,200 | 0.77 | 9 | 12 | 7.27 | NA | 1 5/8 | 0.235 | 0.111 | 2 7/8 | |||

| S-135 EU | 14,500 | 244,600 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 17,832 | 17,034 | NC31 | 4 1/8 | 2 1/8 | 11,900 | 447,100 | 6,400 | 0.82 | 9 | 11 | 7.91 | 3 29/32 | 2 | 0.239 | 0.121 | 2 7/8 | ||

| 14,500 | 244,600 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 17,832 | 17,034 | HT31 | 4 | 2 5/32 | 14,900 | 434,500 | 8,900 | 1.03 | 9 | 13 | 7.83 | 3 23/32 | 2 1/32 | 0.239 | 0.120 | 2 7/8 | |||

| 14,500 | 244,600 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 17,832 | 17,034 | XT31 | 4 | 2 3/8 | 13,200 | 309,100 | 7,900 | 0.91 | 10 | 15 | 7.75 | 3 5/8 | 2 1/4 | 0.242 | 0.118 | 2 7/8 | |||

| S-135 IU | 14,500 | 244,600 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 17,832 | 17,034 | NC26 | 3 5/8 | 1 1/2 | 9,000 | 390,300 | 4,900 | 0.62 | 9 | 10 | 7.64 | 3 17/32 | 1 3/8 | 0.234 | 0.117 | 2 7/8 | ||

| 14,500 | 244,600 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 17,832 | 17,034 | HT26 | 3 1/2 | 1 1/2 | 12,100 | 390,300 | 7,300 | 0.83 | 9 | 12 | 7.60 | 3 5/16 | 1 3/8 | 0.233 | 0.116 | 2 7/8 | |||

| V-150 EU | 16,200 | 271,800 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 19,813 | 18,398 | HT31 | 4 | 2 5/32 | 14,900 | 434,500 | 8,900 | 0.92 | 9 | 13 | 7.83 | 3 25/32 | 2 1/32 | 0.239 | 0.120 | 2 7/8 | ||

| 16,200 | 271,800 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 19,813 | 18,398 | XT31 | 4 | 2 3/8 | 13,200 | 309,100 | 7,900 | 0.81 | 10 | 15 | 7.75 | 3 11/16 | 2 1/4 | 0.242 | 0.118 | 2 7/8 | |||

| V-150 IU | 16,200 | 271,800 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 19,813 | 18,398 | HT26 | 3 1/2 | 1 1/2 | 12,100 | 390,300 | 7,300 | 0.75 | 9 | 12 | 7.60 | 3 3/8 | 1 3/8 | 0.233 | 0.116 | 2 7/8 | ||

| X-95 EU | 10,200 | 172,100 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 12,548 | 12,940 | NC31 | 4 1/8 | 2 5/32 | 11,500 | 434,500 | 6,200 | 1.13 | 9 | 11 | 7.88 | 3 3/4 | 2 1/32 | 0.239 | 0.120 | 2 7/8 | ||

| 10,200 | 172,100 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 12,548 | 12,940 | HT31 | 4 | 2 5/32 | 14,900 | 434,500 | 8,900 | 1.46 | 9 | 13 | 7.83 | 3 19/32 | 2 1/32 | 0.239 | 0.120 | 2 7/8 | |||

| 10,200 | 172,100 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 12,548 | 12,940 | XT31 | 4 | 2 3/8 | 13,200 | 309,100 | 7,900 | 1.29 | 10 | 15 | 7.75 | 3 1/2 | 2 1/4 | 0.242 | 0.118 | 2 7/8 | |||

| X-95 IU | 10,200 | 172,100 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 12,548 | 12,940 | NC26 | 3 1/2 | 1 1/2 | 8,800 | 390,300 | 4,900 | 0.86 | 9 | 10 | 7.50 | 3 3/8 | 1 3/8 | 0.234 | 0.115 | 2 7/8 | ||

| 10,200 | 172,100 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 12,548 | 12,940 | HT26 | 3 3/8 | 1 3/4 | 8,700 | 313,700 | 5,200 | 0.85 | 9 | 12 | 7.27 | NA | 1 5/8 | 0.235 | 0.111 | 2 7/8 | |||

| Z-140 EU | 15,100 | 253,700 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 18,492 | 17,500 | HT31 | 4 | 2 5/32 | 14,900 | 434,500 | 8,900 | 0.99 | 9 | 13 | 7.83 | 3 3/4 | 2 1/32 | 0.239 | 0.120 | 2 7/8 | ||

| 15,100 | 253,700 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 18,492 | 17,500 | XT31 | 4 | 2 3/8 | 13,200 | 309,100 | 7,900 | 0.87 | 10 | 15 | 7.75 | 3 21/32 | 2 1/4 | 0.242 | 0.118 | 2 7/8 | |||

| Z-140 IU | 15,100 | 253,700 | 0.217 | 2.441 | 1.812 | 1.121 | 2.241 | 18,492 | 17,500 | HT26 | 3 1/2 | 1 1/2 | 12,100 | 390,300 | 7,300 | 0.80 | 9 | 12 | 7.60 | 3 11/32 | 1 3/8 | 0.233 | 0.116 | 2 7/8 | ||

| 2 7/8 | 10.40 | E-75 EU | 11,600 | 214,300 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 16,526 | 16,509 | NC31 | 4 1/8 | 2 1/8 | 11,900 | 447,100 | 6,400 | 1.03 | 9 | 11 | 11.14 | 3 13/16 | 2 | 0.188 | 0.170 | 2 7/8 |

| 11,600 | 214,300 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 16,526 | 16,509 | NC26 | 3 1/2 | 1 1/2 | 8,800 | 390,300 | 4,900 | 0.76 | 9 | 10 | 10.79 | 3 13/32 | 1 3/8 | 0.183 | 0.165 | 2 7/8 | |||

| 11,600 | 214,300 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 16,526 | 16,509 | SLH90 | 3 7/8 | 2 | 13,100 | 444,000 | 6,900 | 1.13 | 9 | 11 | 10.95 | 3 19/32 | 1 7/8 | 0.187 | 0.168 | 2 7/8 | |||

| 11,600 | 214,300 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 16,526 | 16,509 | HT31 | 4 1/8 | 2 1/8 | 16,600 | 447,100 | 10,000 | 1.43 | 9 | 13 | 11.26 | 3 19/32 | 2 | 0.188 | 0.172 | 2 7/8 | |||

| 11,600 | 214,300 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 16,526 | 16,509 | XT31 | 3 7/8 | 2 1/8 | 16,600 | 415,100 | 10,000 | 1.43 | 10 | 15 | 11.06 | 3 3/8 | 2 | 0.188 | 0.169 | 2 7/8 | |||

| E-75 IU | 11,600 | 214,300 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 16,526 | 16,509 | HT26 | 3 1/2 | 1 1/2 | 12,100 | 390,300 | 7,300 | 1.04 | 9 | 12 | 10.85 | 3 3/16 | 1 3/8 | 0.182 | 0.166 | 2 7/8 | ||

| 11,600 | 214,300 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 16,526 | 16,509 | XT26 | 3 1/2 | 1 1/2 | 14,800 | 367,400 | 8,900 | 1.28 | 10 | 15 | 11.02 | 2 31/32 | 1 3/8 | 0.181 | 0.168 | 2 7/8 | |||

| G-105 EU | 16,200 | 300,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 23,137 | 23,112 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.81 | 9 | 11 | 11.27 | 3 15/16 | 1 7/8 | 0.187 | 0.172 | 2 7/8 | ||

| 16,200 | 300,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 23,137 | 23,112 | SLH90 | 3 7/8 | 2 | 13,100 | 444,000 | 6,900 | 0.81 | 9 | 11 | 10.95 | 3 23/32 | 1 7/8 | 0.187 | 0.168 | 2 7/8 | |||

| 16,200 | 300,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 23,137 | 23,112 | HT31 | 4 1/8 | 2 1/8 | 16,600 | 447,100 | 10,000 | 1.02 | 9 | 13 | 11.26 | 3 3/4 | 2 | 0.188 | 0.172 | 2 7/8 | |||

| 16,200 | 300,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 23,137 | 23,112 | XT31 | 3 7/8 | 2 1/8 | 16,600 | 415,100 | 10,000 | 1.02 | 10 | 15 | 11.06 | 3 17/32 | 2 | 0.188 | 0.169 | 2 7/8 | |||

| G-105 IU | 16,200 | 300,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 23,137 | 23,112 | NC26 | 3 1/2 | 1 1/2 | 8,800 | 390,300 | 4,900 | 0.54 | 9 | 10 | 10.76 | NA | 1 3/8 | 0.183 | 0.165 | 2 7/8 | ||

| 16,200 | 300,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 23,137 | 23,112 | HT26 | 3 5/8 | 1 1/2 | 13,100 | 390,300 | 7,900 | 0.81 | 9 | 12 | 10.99 | 3 3/8 | 1 3/8 | 0.182 | 0.168 | 2 7/8 | |||

| 16,200 | 300,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 23,137 | 23,112 | XT26 | 3 1/2 | 1 1/2 | 14,800 | 367,400 | 8,900 | 0.91 | 10 | 15 | 11.02 | 3 5/32 | 1 3/8 | 0.181 | 0.168 | 2 7/8 | |||

| S-135 EU | 20,800 | 385,800 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 29,747 | 29,716 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.63 | 9 | 11 | 11.29 | 4 1/16 | 1 7/8 | 0.187 | 0.173 | 2 7/8 | ||

| 20,800 | 385,800 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 29,747 | 29,716 | SLH90 | 3 7/8 | 2 | 13,100 | 444,000 | 6,900 | 0.63 | 9 | 11 | 10.95 | 3 27/32 | 1 7/8 | 0.187 | 0.168 | 2 7/8 | |||

| 20,800 | 385,800 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 29,747 | 29,716 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.91 | 9 | 13 | 11.39 | 3 27/32 | 1 7/8 | 0.187 | 0.174 | 2 7/8 | |||

| 20,800 | 385,800 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 29,747 | 29,716 | XT31 | 3 7/8 | 2 1/8 | 16,600 | 415,100 | 10,000 | 0.80 | 10 | 15 | 11.06 | 3 11/16 | 2 | 0.188 | 0.169 | 2 7/8 | |||

| 20,800 | 385,800 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 29,747 | 29,716 | GPDS31 | 4 1/8 | 2 | 17,200 | 495,700 | 10,300 | 0.83 | 9 | 11 | 11.27 | 3 15/16 | 1 7/8 | 0.187 | 0.172 | 2 7/8 | |||

| S-135 IU | 20,800 | 385,800 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 29,747 | 29,716 | NC26 | 3 5/8 | 1 1/2 | 9,000 | 390,300 | 4,900 | 0.43 | 9 | 10 | 10.90 | NA | 1 3/8 | 0.183 | 0.167 | 2 7/8 | ||

| 20,800 | 385,800 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 29,747 | 29,716 | HT26 | 3 5/8 | 1 1/2 | 13,100 | 390,300 | 7,900 | 0.63 | 9 | 12 | 10.99 | 3 9/16 | 1 3/8 | 0.182 | 0.168 | 2 7/8 | |||

| 20,800 | 385,800 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 29,747 | 29,716 | XT26 | 3 1/2 | 1 3/8 | 15,900 | 401,300 | 9,500 | 0.76 | 10 | 15 | 11.11 | 3 5/16 | 1 1/4 | 0.180 | 0.170 | 2 7/8 | |||

| V-150 EU | 23,100 | 428,700 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 33,052 | 33,018 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.82 | 9 | 13 | 11.39 | 3 29/32 | 1 7/8 | 0.187 | 0.174 | 2 7/8 | ||

| 23,100 | 428,700 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 33,052 | 33,018 | XT31 | 4 | 2 | 20,400 | 463,700 | 12,200 | 0.88 | 10 | 15 | 11.38 | 3 23/32 | 1 7/8 | 0.187 | 0.174 | 2 7/8 | |||

| 23,100 | 428,700 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 33,052 | 33,018 | GPDS31 | 4 1/8 | 2 | 17,200 | 495,700 | 10,300 | 0.74 | 9 | 11 | 11.27 | 4 | 1 7/8 | 0.187 | 0.172 | 2 7/8 | |||

| V-150 IU | 23,100 | 428,700 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 33,052 | 33,018 | HT26 | 3 5/8 | 1 1/4 | 15,300 | 455,100 | 9,200 | 0.66 | 9 | 12 | 11.15 | 3 9/16 | 1 1/8 | 0.180 | 0.171 | 2 7/8 | ||

| 23,100 | 428,700 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 33,052 | 33,018 | XT26 | 3 1/2 | 1 1/4 | 16,400 | 432,200 | 9,800 | 0.71 | 10 | 15 | 11.19 | 3 3/8 | 1 1/8 | 0.179 | 0.171 | 2 7/8 | |||

| X-95 EU | 14,600 | 271,500 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 20,933 | 20,911 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.90 | 9 | 11 | 11.27 | 3 29/32 | 1 7/8 | 0.187 | 0.172 | 2 7/8 | ||

| 14,600 | 271,500 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 20,933 | 20,911 | SLH90 | 3 7/8 | 2 | 13,100 | 444,000 | 6,900 | 0.90 | 9 | 11 | 10.95 | 3 11/16 | 1 7/8 | 0.187 | 0.168 | 2 7/8 | |||

| 14,600 | 271,500 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 20,933 | 20,911 | HT31 | 4 1/8 | 2 1/8 | 16,600 | 447,100 | 10,000 | 1.14 | 9 | 13 | 11.26 | 3 23/32 | 2 | 0.188 | 0.172 | 2 7/8 | |||

| 14,600 | 271,500 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 20,933 | 20,911 | XT31 | 3 7/8 | 2 1/8 | 16,600 | 415,100 | 10,000 | 1.14 | 10 | 15 | 11.06 | 3 1/2 | 2 | 0.188 | 0.169 | 2 7/8 | |||

| X-95 IU | 14,600 | 271,500 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 20,933 | 20,911 | NC26 | 3 1/2 | 1 1/2 | 8,800 | 390,300 | 4,900 | 0.60 | 9 | 10 | 10.76 | NA | 1 3/8 | 0.183 | 0.165 | 2 7/8 | ||

| 14,600 | 271,500 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 20,933 | 20,911 | HT26 | 3 1/2 | 1 1/2 | 12,100 | 390,300 | 7,300 | 0.83 | 9 | 12 | 10.85 | 3 5/16 | 1 3/8 | 0.182 | 0.166 | 2 7/8 | |||

| 14,600 | 271,500 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 20,933 | 20,911 | XT26 | 3 1/2 | 1 1/2 | 14,800 | 367,400 | 8,900 | 1.01 | 10 | 15 | 11.02 | 3 3/32 | 1 3/8 | 0.181 | 0.168 | 2 7/8 | |||

| Z-140 EU | 21,600 | 400,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 30,849 | 30,817 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.88 | 9 | 13 | 11.39 | 3 7/8 | 1 7/8 | 0.187 | 0.174 | 2 7/8 | ||

| 21,600 | 400,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 30,849 | 30,817 | XT31 | 4 | 2 | 20,400 | 463,700 | 12,200 | 0.94 | 10 | 15 | 11.38 | 3 21/32 | 1 7/8 | 0.187 | 0.174 | 2 7/8 | |||

| 21,600 | 400,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 30,849 | 30,817 | GPDS31 | 4 1/8 | 2 | 17,200 | 495,700 | 10,300 | 0.80 | 9 | 11 | 11.27 | 3 15/16 | 1 7/8 | 0.187 | 0.172 | 2 7/8 | |||

| Z-140 IU | 21,600 | 400,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 30,849 | 30,817 | HT26 | 3 5/8 | 1 1/4 | 15,300 | 455,100 | 9,200 | 0.71 | 9 | 12 | 11.15 | 3 17/32 | 1 1/8 | 0.180 | 0.171 | 2 7/8 | ||

| 21,600 | 400,100 | 0.362 | 2.151 | 2.858 | 1.602 | 3.204 | 30,849 | 30,817 | XT26 | 3 1/2 | 1 1/4 | 16,400 | 432,200 | 9,800 | 0.76 | 10 | 15 | 11.19 | 3 5/16 | 1 1/8 | 0.179 | 0.171 | 2 7/8 | |||

3.5″ Drill Pipe Specifications

| Pipe Data | Tool Joint Data | Assembly Data | ||||||||||||||||||||||||

| Size Outer D | Nominal Weight | Grade and Upset Type | Torsional Yield Strength | Tensile Yield Strength | Wall Thickness | Nominal ID | Pipe Body Section Area | Pipe Body Section Modulus | Pipe Body Polar Section Modulus | Internal Pressure | Collapse Pressure | Connection Type | Outside Diameter | Inside Diameter | Torsional Yield Strength | Tensile Yield Strength | Make-up Torque | Torsional Ratio Tool Joint to Pipe | * Pin Tong Space | * Box Tong Space | Adjusted Weight | Minimum Tool Joint O.D. for Prem. Class | Drift Diameter | Capacity | Displace- ment | Size Outer D |

| 3 1/2 | 9.50 | E-75 EU | 14,100 | 194,300 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 9,525 | 10,001 | NC38 | 4 3/4 | 2 11/16 | 18,100 | 587,300 | 9,700 | 1.28 | 10 | 12.5 | 11.07 | 4 13/32 | 2 9/16 | 0.360 | 0.169 | 3 1/2 |

| 14,100 | 194,300 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 9,525 | 10,001 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 1.79 | 10 | 15.5 | 11.31 | 4 5/32 | 2 9/16 | 0.360 | 0.173 | 3 1/2 | |||

| 14,100 | 194,300 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 9,525 | 10,001 | SLH90 | 4 3/4 | 2 11/16 | 18,688 | 534,200 | 11,100 | 1.33 | 10 | 12.5 | 11.07 | 4 3/16 | 2 9/16 | 0.360 | 0.169 | 3 1/2 | |||

| 14,100 | 194,300 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 9,525 | 10,001 | XT38 | 4 3/4 | 2 13/16 | 23,900 | 473,000 | 14,300 | 1.70 | 10 | 15 | 11.08 | 4 | 2 11/16 | 0.362 | 0.170 | 3 1/2 | |||

| 3 1/2 | 9.50 | E-75 IU | 14,100 | 194,300 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 9,525 | 10,001 | NC31 | 4 1/8 | 2 1/8 | 11,900 | 447,100 | 6,400 | 0.84 | 9 | 11 | 10.49 | 3 7/8 | 2 | 0.354 | 0.161 | 3 1/2 |

| 14,100 | 194,300 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 9,525 | 10,001 | HT31 | 4 1/8 | 2 1/8 | 16,600 | 447,100 | 10,000 | 1.18 | 9 | 13 | 10.62 | 3 11/16 | 2 | 0.353 | 0.162 | 3 1/2 | |||

| 14,100 | 194,300 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 9,525 | 10,001 | XT31 | 4 | 2 1/8 | 18,600 | 415,100 | 11,200 | 1.32 | 10 | 15 | 10.61 | 3 1/2 | 2 | 0.352 | 0.162 | 3 1/2 | |||

| 3 1/2 | 9.50 | G-105 EU | 19,800 | 272,000 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 13,335 | 13,055 | NC38 | 4 3/4 | 2 11/16 | 18,100 | 587,300 | 9,700 | 0.91 | 10 | 12.5 | 11.07 | 4 17/32 | 2 9/16 | 0.360 | 0.169 | 3 1/2 |

| 19,800 | 272,000 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 13,335 | 13,055 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 1.28 | 10 | 15.5 | 11.31 | 4 9/32 | 2 9/16 | 0.360 | 0.173 | 3 1/2 | |||

| 19,800 | 272,000 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 13,335 | 13,055 | SLH90 | 4 3/4 | 2 11/16 | 18,700 | 534,200 | 11,100 | 0.94 | 10 | 12.5 | 11.07 | 4 5/16 | 2 9/16 | 0.360 | 0.169 | 3 1/2 | |||

| 19,800 | 272,000 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 13,335 | 13,055 | XT38 | 4 3/4 | 2 13/16 | 23,900 | 473,000 | 14,300 | 1.21 | 10 | 15 | 11.08 | 4 5/32 | 2 11/16 | 0.362 | 0.170 | 3 1/2 | |||

| 3 1/2 | 9.50 | G-105 IU | 19,800 | 272,000 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 13,335 | 13,055 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.67 | 9 | 11 | 10.61 | 4 1/16 | 1 7/8 | 0.352 | 0.162 | 3 1/2 |

| 19,800 | 272,000 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 13,335 | 13,055 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.95 | 9 | 13 | 10.74 | 3 27/32 | 1 7/8 | 0.351 | 0.164 | 3 1/2 | |||

| 19,800 | 272,000 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 13,335 | 13,055 | XT31 | 4 | 2 1/8 | 18,600 | 415,100 | 11,200 | 0.94 | 10 | 15 | 10.61 | 3 11/16 | 2 | 0.352 | 0.162 | 3 1/2 | |||

| 3 1/2 | 9.50 | S-135 EU | 25,500 | 349,700 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,145 | 15,748 | NC38 | 4 7/8 | 2 9/16 | 20,200 | 649,200 | 10,700 | 0.79 | 10 | 12.5 | 11.45 | 4 21/32 | 2 7/16 | 0.358 | 0.175 | 3 1/2 |

| 25,500 | 349,700 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,145 | 15,748 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 0.99 | 10 | 15.5 | 11.31 | 4 7/16 | 2 9/16 | 0.360 | 0.173 | 3 1/2 | |||

| 25,500 | 349,700 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,145 | 15,748 | SLH90 | 4 3/4 | 2 9/16 | 20,900 | 596,100 | 12,400 | 0.82 | 10 | 12.5 | 11.24 | 4 7/16 | 2 7/16 | 0.358 | 0.172 | 3 1/2 | |||

| 25,500 | 349,700 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,145 | 15,748 | XT38 | 4 3/4 | 2 13/16 | 23,900 | 473,000 | 14,300 | 0.94 | 10 | 15 | 11.08 | 4 9/32 | 2 11/16 | 0.362 | 0.170 | 3 1/2 | |||

| 3 1/2 | 9.50 | S-135 IU | 25,500 | 349,700 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,145 | 15,748 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.52 | 9 | 11 | 10.61 | NA | 1 7/8 | 0.352 | 0.162 | 3 1/2 |

| 25,500 | 349,700 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,145 | 15,748 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.74 | 9 | 13 | 10.74 | 4 | 1 7/8 | 0.351 | 0.164 | 3 1/2 | |||

| 25,500 | 349,700 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,145 | 15,748 | XT31 | 4 | 2 | 20,400 | 463,700 | 12,200 | 0.80 | 10 | 15 | 10.74 | 3 13/16 | 1 7/8 | 0.350 | 0.164 | 3 1/2 | |||

| 3 1/2 | 9.50 | V-150 EU | 28,300 | 388,500 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 19,050 | 16,943 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 0.89 | 10 | 15.5 | 11.31 | 4 1/2 | 2 9/16 | 0.360 | 0.173 | 3 1/2 |

| 28,300 | 388,500 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 19,050 | 16,943 | XT38 | 4 3/4 | 2 13/16 | 23,900 | 473,000 | 14,300 | 0.84 | 10 | 15 | 11.08 | 4 11/32 | 2 11/16 | 0.362 | 0.170 | 3 1/2 | |||

| 3 1/2 | 9.50 | V-150 IU | 28,300 | 388,500 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 19,050 | 16,943 | HT31 | 4 1/4 | 1 3/4 | 23,400 | 584,100 | 14,000 | 0.83 | 9 | 13 | 11.14 | 4 | 1 5/8 | 0.348 | 0.170 | 3 1/2 |

| 28,300 | 388,500 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 19,050 | 16,943 | XT31 | 4 | 2 | 20,400 | 463,700 | 12,200 | 0.72 | 10 | 15 | 10.74 | 3 29/32 | 1 7/8 | 0.350 | 0.164 | 3 1/2 | |||

| 3 1/2 | 9.50 | X-95 EU | 17,900 | 246,100 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 12,065 | 12,077 | NC38 | 4 3/4 | 2 11/16 | 18,100 | 587,300 | 9,700 | 1.01 | 10 | 12.5 | 11.07 | 4 15/32 | 2 9/16 | 0.360 | 0.169 | 3 1/2 |

| 17,900 | 246,100 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 12,065 | 12,077 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 1.41 | 10 | 15.5 | 11.31 | 4 1/4 | 2 9/16 | 0.360 | 0.173 | 3 1/2 | |||

| 17,900 | 246,100 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 12,065 | 12,077 | SLH90 | 4 3/4 | 2 11/16 | 18,700 | 534,200 | 11,100 | 1.04 | 10 | 12.5 | 11.07 | 4 9/32 | 2 9/16 | 0.360 | 0.169 | 3 1/2 | |||

| 17,900 | 246,100 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 12,065 | 12,077 | XT38 | 4 3/4 | 2 13/16 | 23,900 | 473,000 | 14,300 | 1.34 | 10 | 15 | 11.08 | 4 3/32 | 2 11/16 | 0.362 | 0.170 | 3 1/2 | |||

| 3 1/2 | 9.50 | X-95 IU | 17,900 | 246,100 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 12,065 | 12,077 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.74 | 9 | 11 | 10.61 | 4 | 1 7/8 | 0.352 | 0.162 | 3 1/2 |

| 17,900 | 246,100 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 12,065 | 12,077 | HT31 | 4 1/8 | 2 1/8 | 16,600 | 447,100 | 10,000 | 0.93 | 9 | 13 | 10.62 | 3 13/16 | 2 | 0.353 | 0.162 | 3 1/2 | |||

| 17,900 | 246,100 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 12,065 | 12,077 | XT31 | 4 | 2 1/8 | 18,600 | 415,100 | 11,200 | 1.04 | 10 | 15 | 10.61 | 3 5/8 | 2 | 0.352 | 0.162 | 3 1/2 | |||

| 3 1/2 | 9.50 | Z-140 EU | 26,400 | 362,600 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,780 | 16,158 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 0.96 | 10 | 15.5 | 11.31 | 4 15/32 | 2 9/16 | 0.360 | 0.173 | 3 1/2 |

| 26,400 | 362,600 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,780 | 16,158 | XT38 | 4 3/4 | 2 13/16 | 23,900 | 473,000 | 14,300 | 0.91 | 10 | 15 | 11.08 | 4 5/16 | 2 11/16 | 0.362 | 0.170 | 3 1/2 | |||

| 3 1/2 | 9.50 | Z-140 IU | 26,400 | 362,600 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,780 | 16,158 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.72 | 9 | 13 | 10.74 | 4 1/32 | 1 7/8 | 0.351 | 0.164 | 3 1/2 |

| 26,400 | 362,600 | 0.254 | 2.992 | 2.590 | 1.961 | 3.923 | 17,780 | 16,158 | XT31 | 4 | 2 | 20,400 | 463,700 | 12,200 | 0.77 | 10 | 15 | 10.74 | 3 27/32 | 1 7/8 | 0.350 | 0.164 | 3 1/2 | |||

| 3 1/2 | 13.30 | E-75 EU | 18,600 | 271,600 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 13,800 | 14,113 | NC38 | 4 3/4 | 2 11/16 | 18,100 | 587,300 | 9,700 | 0.97 | 10 | 12.5 | 14.24 | 4 1/2 | 2 9/16 | 0.310 | 0.218 | 3 1/2 |

| 18,600 | 271,600 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 13,800 | 14,113 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 1.36 | 10 | 15.5 | 14.45 | 4 1/4 | 2 9/16 | 0.310 | 0.221 | 3 1/2 | |||

| 18,600 | 271,600 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 13,800 | 14,113 | SLH90 | 4 3/4 | 2 11/16 | 18,700 | 534,200 | 11,100 | 1.01 | 10 | 12.5 | 14.24 | 4 9/32 | 2 9/16 | 0.310 | 0.218 | 3 1/2 | |||

| 18,600 | 271,600 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 13,800 | 14,113 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 1.49 | 10 | 15 | 14.42 | 4 1/32 | 2 9/16 | 0.310 | 0.221 | 3 1/2 | |||

| 3 1/2 | 13.30 | E-75 IU | 18,600 | 271,600 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 13,800 | 14,113 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.71 | 9 | 11 | 13.93 | 4 1/32 | 1 7/8 | 0.302 | 0.213 | 3 1/2 |

| 18,600 | 271,600 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 13,800 | 14,113 | HT31 | 4 1/8 | 2 1/8 | 16,600 | 447,100 | 10,000 | 0.89 | 9 | 13 | 13.91 | 3 27/32 | 2 | 0.303 | 0.213 | 3 1/2 | |||

| 18,600 | 271,600 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 13,800 | 14,113 | XT31 | 4 | 2 1/8 | 18,600 | 415,100 | 11,200 | 1.00 | 10 | 15 | 13.87 | 3 5/8 | 2 | 0.302 | 0.212 | 3 1/2 | |||

| 3 1/2 | 13.30 | G-105 EU | 26,000 | 380,200 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 19,320 | 19,758 | NC38 | 5 | 2 7/16 | 22,200 | 708,100 | 11,700 | 0.85 | 10 | 12.5 | 15.00 | 4 21/32 | 2 5/16 | 0.306 | 0.229 | 3 1/2 |

| 26,000 | 380,200 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 19,320 | 19,758 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 0.97 | 10 | 15.5 | 14.45 | 4 7/16 | 2 9/16 | 0.310 | 0.221 | 3 1/2 | |||

| 26,000 | 380,200 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 19,320 | 19,758 | SLH90 | 4 3/4 | 2 9/16 | 20,900 | 596,100 | 12,400 | 0.80 | 10 | 12.5 | 14.41 | 4 7/16 | 2 7/16 | 0.308 | 0.220 | 3 1/2 | |||

| 26,000 | 380,200 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 19,320 | 19,758 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 1.07 | 10 | 15 | 14.42 | 4 7/32 | 2 9/16 | 0.310 | 0.221 | 3 1/2 | |||

| 3 1/2 | 13.30 | G-105 IU | 26,000 | 380,200 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 19,320 | 19,758 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.51 | 9 | 11 | 13.93 | NA | 1 7/8 | 0.302 | 0.213 | 3 1/2 |

| 26,000 | 380,200 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 19,320 | 19,758 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.73 | 9 | 13 | 14.04 | 4 | 1 7/8 | 0.301 | 0.215 | 3 1/2 | |||

| 26,000 | 380,200 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 19,320 | 19,758 | XT31 | 4 1/8 | 2 | 21,100 | 463,700 | 12,700 | 0.81 | 10 | 15 | 14.21 | 3 13/16 | 1 7/8 | 0.300 | 0.217 | 3 1/2 | |||

| 3 1/2 | 13.30 | S-135 EU | 33,400 | 488,800 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 24,840 | 25,404 | NC38 | 5 | 2 1/8 | 26,500 | 842,400 | 14,000 | 0.79 | 10 | 12.5 | 15.37 | 4 13/16 | 2 | 0.302 | 0.235 | 3 1/2 |

| 33,400 | 488,800 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 24,840 | 25,404 | HT38 | 4 3/4 | 2 9/16 | 26,900 | 649,200 | 16,100 | 0.81 | 10 | 15.5 | 14.63 | 4 9/16 | 2 7/16 | 0.308 | 0.224 | 3 1/2 | |||

| 33,400 | 488,800 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 24,840 | 25,404 | SLH90 | 4 3/4 | 2 9/16 | 20,900 | 596,100 | 12,400 | 0.63 | 10 | 12.5 | 14.41 | 4 19/32 | 2 7/16 | 0.308 | 0.220 | 3 1/2 | |||

| 33,400 | 488,800 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 24,840 | 25,404 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 0.83 | 10 | 15 | 14.42 | 4 13/32 | 2 9/16 | 0.310 | 0.221 | 3 1/2 | |||

| 33,400 | 488,800 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 24,840 | 25,404 | GPDS38 | 4 7/8 | 2 9/16 | 25,700 | 649,200 | 15,400 | 0.77 | 10 | 12.5 | 14.62 | 4 11/16 | 2 7/16 | 0.308 | 0.224 | 3 1/2 | |||

| 3 1/2 | 13.30 | S-135 IU | 33,400 | 488,800 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 24,840 | 25,404 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.40 | 9 | 11 | 13.93 | NA | 1 7/8 | 0.302 | 0.213 | 3 1/2 |

| 33,400 | 488,800 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 24,840 | 25,404 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.57 | 9 | 13 | 14.04 | NA | 1 7/8 | 0.301 | 0.215 | 3 1/2 | |||

| 33,400 | 488,800 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 24,840 | 25,404 | XT31 | 4 1/8 | 1 7/8 | 23,400 | 509,400 | 14,000 | 0.70 | 10 | 15 | 14.34 | 3 31/32 | 1 3/4 | 0.298 | 0.219 | 3 1/2 | |||

| 3 1/2 | 13.30 | V-150 EU | 37,100 | 543,100 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 27,600 | 28,226 | HT38 | 4 3/4 | 2 9/16 | 26,900 | 649,200 | 16,100 | 0.73 | 10 | 15.5 | 14.63 | 4 5/8 | 2 7/16 | 0.308 | 0.224 | 3 1/2 |

| 37,100 | 543,100 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 27,600 | 28,226 | XT38 | 4 3/4 | 2 9/16 | 31,300 | 599,600 | 18,800 | 0.84 | 10 | 15 | 14.59 | 4 7/16 | 2 7/16 | 0.308 | 0.223 | 3 1/2 | |||

| 37,100 | 543,100 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 27,600 | 28,226 | GPDS38 | 5 | 2 9/16 | 25,800 | 649,200 | 15,500 | 0.70 | 10 | 12.5 | 14.84 | 4 3/4 | 2 7/16 | 0.308 | 0.227 | 3 1/2 | |||

| 3 1/2 | 13.30 | V-150 IU | 37,100 | 543,100 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 27,600 | 28,226 | HT31 | 4 1/4 | 1 3/4 | 23,400 | 584,100 | 14,000 | 0.63 | 9 | 13 | 14.47 | 4 1/4 | 1 5/8 | 0.298 | 0.221 | 3 1/2 |

| 37,100 | 543,100 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 27,600 | 28,226 | XT31 | 4 1/8 | 1 3/4 | 25,000 | 552,100 | 15,000 | 0.67 | 10 | 15 | 14.47 | 4 1/16 | 1 5/8 | 0.297 | 0.221 | 3 1/2 | |||

| 3 1/2 | 13.30 | X-95 EU | 23,500 | 344,000 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 17,480 | 17,877 | NC38 | 5 | 2 9/16 | 20,300 | 649,200 | 10,700 | 0.86 | 10 | 12.5 | 14.84 | 4 19/32 | 2 7/16 | 0.308 | 0.227 | 3 1/2 |

| 23,500 | 344,000 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 17,480 | 17,877 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 1.08 | 10 | 15.5 | 14.45 | 4 3/8 | 2 9/16 | 0.310 | 0.221 | 3 1/2 | |||

| 23,500 | 344,000 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 17,480 | 17,877 | SLH90 | 4 3/4 | 2 11/16 | 18,700 | 534,200 | 11,100 | 0.80 | 10 | 12.5 | 14.24 | 4 3/8 | 2 9/16 | 0.310 | 0.218 | 3 1/2 | |||

| 23,500 | 344,000 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 17,480 | 17,877 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 1.18 | 10 | 15 | 14.42 | 4 5/32 | 2 9/16 | 0.310 | 0.221 | 3 1/2 | |||

| 3 1/2 | 13.30 | X-95 IU | 23,500 | 344,000 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 17,480 | 17,877 | NC31 | 4 1/8 | 2 | 13,200 | 495,700 | 7,100 | 0.56 | 9 | 11 | 13.93 | NA | 1 7/8 | 0.302 | 0.213 | 3 1/2 |

| 23,500 | 344,000 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 17,480 | 17,877 | HT31 | 4 1/8 | 2 | 18,900 | 495,700 | 11,300 | 0.80 | 9 | 13 | 14.04 | 3 15/16 | 1 7/8 | 0.301 | 0.215 | 3 1/2 | |||

| 23,500 | 344,000 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 17,480 | 17,877 | XT31 | 4 | 2 1/8 | 18,600 | 415,100 | 11,200 | 0.79 | 10 | 15 | 13.87 | 3 25/32 | 2 | 0.302 | 0.212 | 3 1/2 | |||

| 3 1/2 | 13.30 | Z-140 EU | 34,600 | 506,900 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 25,760 | 26,345 | HT38 | 4 3/4 | 2 9/16 | 26,900 | 649,200 | 16,100 | 0.78 | 10 | 15.5 | 14.63 | 4 9/16 | 2 7/16 | 0.308 | 0.224 | 3 1/2 |

| 34,600 | 506,900 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 25,760 | 26,345 | XT38 | 4 3/4 | 2 9/16 | 31,300 | 599,600 | 18,800 | 0.90 | 10 | 15 | 14.59 | 4 3/8 | 2 7/16 | 0.308 | 0.223 | 3 1/2 | |||

| 34,600 | 506,900 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 25,760 | 26,345 | GPDS38 | 5 | 2 9/16 | 25,800 | 649,200 | 15,500 | 0.75 | 10 | 12.5 | 14.84 | 4 11/16 | 2 7/16 | 0.308 | 0.227 | 3 1/2 | |||

| 3 1/2 | 13.30 | Z-140 IU | 34,600 | 506,900 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 25,760 | 26,345 | HT31 | 4 1/8 | 1 7/8 | 19,900 | 541,400 | 11,900 | 0.58 | 9 | 13 | 14.17 | NA | 1 3/4 | 0.300 | 0.217 | 3 1/2 |

| 34,600 | 506,900 | 0.368 | 2.764 | 3.621 | 2.572 | 5.144 | 25,760 | 26,345 | XT31 | 4 1/8 | 1 3/4 | 25,000 | 552,100 | 15,000 | 0.72 | 10 | 15 | 14.47 | 3 31/32 | 1 5/8 | 0.297 | 0.221 | 3 1/2 | |||

| 3 1/2 | 15.50 | E-75 EU | 21,100 | 322,800 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 16,838 | 16,774 | NC38 | 5 | 2 9/16 | 20,300 | 649,200 | 10,700 | 0.96 | 10 | 12.5 | 16.94 | 4 17/32 | 2 7/16 | 0.276 | 0.259 | 3 1/2 |

| 21,100 | 322,800 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 16,838 | 16,774 | HT38 | 4 3/4 | 2 9/16 | 26,900 | 649,200 | 16,100 | 1.27 | 10 | 15.5 | 16.71 | 4 1/4 | 2 7/16 | 0.276 | 0.256 | 3 1/2 | |||

| 21,100 | 322,800 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 16,838 | 16,774 | XT38 | 4 3/4 | 2 9/16 | 31,300 | 599,600 | 18,800 | 1.48 | 10 | 15 | 16.68 | 4 1/32 | 2 7/16 | 0.276 | 0.255 | 3 1/2 | |||

| G-105 EU | 29,500 | 451,900 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 23,573 | 23,484 | NC38 | 5 | 2 1/8 | 26,500 | 842,400 | 14,000 | 0.90 | 10 | 12.5 | 17.50 | 4 23/32 | 2 | 0.269 | 0.268 | 3 1/2 | ||

| 29,500 | 451,900 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 23,573 | 23,484 | HT38 | 4 3/4 | 2 9/16 | 26,900 | 649,200 | 16,100 | 0.91 | 10 | 15.5 | 16.71 | 4 7/16 | 2 7/16 | 0.276 | 0.256 | 3 1/2 | |||

| 29,500 | 451,900 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 23,573 | 23,484 | NC40 | 5 1/4 | 2 9/16 | 27,800 | 838,300 | 14,600 | 0.94 | 9 | 12 | 17.24 | 4 15/16 | 2 7/16 | 0.276 | 0.264 | 3 1/2 | |||

| 29,500 | 451,900 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 23,573 | 23,484 | XT38 | 4 3/4 | 2 9/16 | 31,300 | 599,600 | 18,800 | 1.06 | 10 | 15 | 16.68 | 4 1/4 | 2 7/16 | 0.276 | 0.255 | 3 1/2 | |||

| S-135 EU | 38,000 | 581,000 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 30,308 | 30,194 | NC38 | 5 | 2 1/8 | 26,500 | 842,400 | 14,000 | 0.70 | 10 | 12.5 | 17.50 | 4 29/32 | 2 | 0.269 | 0.268 | 3 1/2 | ||

| 38,000 | 581,000 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 30,308 | 30,194 | HT38 | 4 3/4 | 2 7/16 | 28,400 | 708,100 | 17,000 | 0.75 | 10 | 15.5 | 16.90 | 4 19/32 | 2 5/16 | 0.273 | 0.258 | 3 1/2 | |||

| 38,000 | 581,000 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 30,308 | 30,194 | NC40 | 5 1/2 | 2 1/4 | 32,900 | 980,000 | 17,100 | 0.87 | 10 | 12.5 | 18.31 | 5 3/32 | 2 1/8 | 0.271 | 0.280 | 3 1/2 | |||

| 38,000 | 581,000 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 30,308 | 30,194 | XT38 | 4 3/4 | 2 7/16 | 34,200 | 658,500 | 20,500 | 0.90 | 10 | 15 | 16.86 | 4 3/8 | 2 5/16 | 0.273 | 0.258 | 3 1/2 | |||

| 38,000 | 581,000 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 30,308 | 30,194 | XT39 | 4 7/8 | 2 7/16 | 38,500 | 788,600 | 23,100 | 1.01 | 10 | 15 | 17.09 | 4 3/8 | 2 5/16 | 0.273 | 0.261 | 3 1/2 | |||

| 38,000 | 581,000 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 30,308 | 30,194 | GPDS38 | 5 | 2 7/16 | 29,200 | 708,100 | 17,500 | 0.77 | 10 | 12.5 | 17.11 | 4 23/32 | 2 5/16 | 0.274 | 0.262 | 3 1/2 | |||

| V-150 EU | 42,200 | 645,500 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 33,675 | 33,549 | HT38 | 5 | 2 1/4 | 37,700 | 790,900 | 22,600 | 0.89 | 10 | 15.5 | 17.63 | 4 19/32 | 2 1/8 | 0.270 | 0.270 | 3 1/2 | ||

| 42,200 | 645,500 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 33,675 | 33,549 | XT38 | 4 3/4 | 2 1/4 | 36,300 | 741,400 | 21,800 | 0.86 | 10 | 15 | 17.11 | 4 13/32 | 2 1/8 | 0.271 | 0.262 | 3 1/2 | |||

| 42,200 | 645,500 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 33,675 | 33,549 | XT39 | 4 7/8 | 2 1/4 | 40,700 | 871,400 | 24,400 | 0.96 | 10 | 15 | 17.35 | 4 3/8 | 2 1/8 | 0.270 | 0.265 | 3 1/2 | |||

| 42,200 | 645,500 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 33,675 | 33,549 | GPDS38 | 5 | 2 1/4 | 33,900 | 790,900 | 20,300 | 0.80 | 10 | 12.5 | 17.35 | 4 23/32 | 2 1/8 | 0.271 | 0.265 | 3 1/2 | |||

| X-95 EU | 26,700 | 408,800 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 21,328 | 21,247 | NC38 | 5 | 2 7/16 | 22,200 | 708,100 | 11,700 | 0.83 | 10 | 12.5 | 17.11 | 4 21/32 | 2 5/16 | 0.274 | 0.262 | 3 1/2 | ||

| 26,700 | 408,800 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 21,328 | 21,247 | HT38 | 4 3/4 | 2 9/16 | 26,900 | 649,200 | 16,100 | 1.01 | 10 | 15.5 | 16.71 | 4 3/8 | 2 7/16 | 0.276 | 0.256 | 3 1/2 | |||

| 26,700 | 408,800 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 21,328 | 21,247 | XT38 | 4 3/4 | 2 9/16 | 31,300 | 599,600 | 18,800 | 1.17 | 10 | 15 | 16.68 | 4 5/32 | 2 7/16 | 0.276 | 0.255 | 3 1/2 | |||

| Z-140 EU | 39,400 | 602,500 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 31,430 | 31,312 | HT38 | 4 3/4 | 2 7/16 | 28,400 | 708,100 | 17,000 | 0.72 | 10 | 15.5 | 16.90 | 4 5/8 | 2 5/16 | 0.273 | 0.258 | 3 1/2 | ||

| 39,400 | 602,500 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 31,430 | 31,312 | XT38 | 4 3/4 | 2 7/16 | 34,200 | 658,500 | 20,500 | 0.87 | 10 | 15 | 16.86 | 4 13/32 | 2 5/16 | 0.273 | 0.258 | 3 1/2 | |||

| 39,400 | 602,500 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 31,430 | 31,312 | XT39 | 4 7/8 | 2 7/16 | 38,500 | 788,600 | 23,100 | 0.98 | 10 | 15 | 17.09 | 4 13/32 | 2 5/16 | 0.273 | 0.261 | 3 1/2 | |||

| 39,400 | 602,500 | 0.449 | 2.602 | 4.304 | 2.923 | 5.847 | 31,430 | 31,312 | GPDS38 | 5 | 2 7/16 | 29,200 | 708,100 | 17,500 | 0.74 | 10 | 12.5 | 17.11 | 4 3/4 | 2 5/16 | 0.274 | 0.262 | 3 1/2 | |||

4″ Drill Pipe Specifications

| Pipe Data | Tool Joint Data | Assembly Data | ||||||||||||||||||||||||

| Size Outer D | Nominal Weight | Grade and Upset Type | Torsional Yield Strength | Tensile Yield Strength | Wall Thickness | Nominal ID | Pipe Body Section Area | Pipe Body Section Modulus | Pipe Body Polar Section Modulus | Internal Pressure | Collapse Pressure | Connection Type | Outside Diameter | Inside Diameter | Torsional Yield Strength | Tensile Yield Strength | Make-up Torque | Torsional Ratio Tool Joint to Pipe | * Pin Tong Space | * Box Tong Space | Adjusted Weight | Minimum Tool Joint O.D. for Prem. Class | Drift Diameter | Capacity | Displace- ment | Size Outer D |

| 4 | 11.85 | E-75 IU | 19,500 | 230,800 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 8,597 | 8,381 | NC40 | 5 1/4 | 2 13/16 | 23,500 | 711,600 | 12,400 | 1.21 | 9 | 12 | 13.41 | 4 3/4 | 2 11/16 | 0.481 | 0.205 | 4 |

| 19,500 | 230,800 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 8,597 | 8,381 | SH | 4 3/4 | 2 9/16 | 15,300 | 512,000 | 8,100 | 0.78 | 9 | 12 | 12.91 | 4 3/8 | 2 7/16 | 0.477 | 0.198 | 4 | |||

| 19,500 | 230,800 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 8,597 | 8,381 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 1.30 | 10 | 15.5 | 13.08 | 4 9/32 | 2 9/16 | 0.477 | 0.200 | 4 | |||

| 19,500 | 230,800 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 8,597 | 8,381 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 1.42 | 10 | 15 | 13.04 | 4 1/16 | 2 9/16 | 0.477 | 0.199 | 4 | |||

| 19,500 | 230,800 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 8,597 | 8,381 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 1.69 | 10 | 15 | 13.08 | 4 5/32 | 2 11/16 | 0.479 | 0.200 | 4 | |||

| 4 | 11.85 | G-105 IU | 27,300 | 323,100 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 12,036 | 10,708 | NC40 | 5 1/4 | 2 13/16 | 23,500 | 711,600 | 12,400 | 0.86 | 9 | 12 | 13.41 | 4 29/32 | 2 11/16 | 0.481 | 0.205 | 4 |

| 27,300 | 323,100 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 12,036 | 10,708 | SH | 4 3/4 | 2 9/16 | 15,300 | 512,000 | 8,100 | 0.56 | 9 | 12 | 12.91 | 4 9/16 | 2 7/16 | 0.477 | 0.198 | 4 | |||

| 27,300 | 323,100 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 12,036 | 10,708 | HT38 | 4 3/4 | 2 9/16 | 26,900 | 649,200 | 16,100 | 0.99 | 10 | 15.5 | 13.27 | 4 13/32 | 2 7/16 | 0.475 | 0.203 | 4 | |||

| 27,300 | 323,100 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 12,036 | 10,708 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 1.01 | 10 | 15 | 13.04 | 4 9/32 | 2 9/16 | 0.477 | 0.199 | 4 | |||

| 27,300 | 323,100 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 12,036 | 10,708 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 1.21 | 10 | 15 | 13.08 | 4 11/32 | 2 11/16 | 0.479 | 0.200 | 4 | |||

| 4 | 11.85 | S-135 IU | 35,100 | 415,400 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 15,474 | 12,618 | NC40 | 5 1/2 | 2 9/16 | 28,100 | 838,300 | 14,600 | 0.80 | 9 | 12 | 14.23 | 5 1/16 | 2 7/16 | 0.476 | 0.218 | 4 |

| 35,100 | 415,400 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 15,474 | 12,618 | SH | 4 3/4 | 2 9/16 | 15,300 | 512,000 | 8,100 | 0.44 | 9 | 12 | 12.91 | 4 23/32 | 2 7/16 | 0.477 | 0.198 | 4 | |||

| 35,100 | 415,400 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 15,474 | 12,618 | HT38 | 4 3/4 | 2 7/16 | 28,400 | 708,100 | 17,000 | 0.81 | 10 | 15.5 | 13.45 | 4 17/32 | 2 5/16 | 0.473 | 0.206 | 4 | |||

| 35,100 | 415,400 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 15,474 | 12,618 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 0.79 | 10 | 15 | 13.04 | 4 7/16 | 2 9/16 | 0.477 | 0.199 | 4 | |||

| 35,100 | 415,400 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 15,474 | 12,618 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 0.94 | 10 | 15 | 13.08 | 4 1/2 | 2 11/16 | 0.479 | 0.200 | 4 | |||

| 4 | 11.85 | V-150 IU | 38,900 | 461,500 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 17,194 | 13,404 | HT38 | 5 | 2 7/16 | 33,000 | 708,100 | 19,800 | 0.85 | 10 | 15.5 | 13.93 | 4 5/8 | 2 5/16 | 0.472 | 0.213 | 4 |

| 38,900 | 461,500 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 17,194 | 13,404 | XT38 | 4 3/4 | 2 9/16 | 31,300 | 599,600 | 18,800 | 0.80 | 10 | 15 | 13.23 | 4 15/32 | 2 7/16 | 0.475 | 0.202 | 4 | |||

| 38,900 | 461,500 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 17,194 | 13,404 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 0.85 | 10 | 15 | 13.08 | 4 19/32 | 2 11/16 | 0.479 | 0.200 | 4 | |||

| 4 | 11.85 | X-95 IU | 24,700 | 292,300 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 10,889 | 9,978 | NC40 | 5 1/4 | 2 13/16 | 23,500 | 711,600 | 12,400 | 0.95 | 9 | 12 | 13.41 | 4 27/32 | 2 11/16 | 0.481 | 0.205 | 4 |

| 24,700 | 292,300 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 10,889 | 9,978 | SH | 4 3/4 | 2 9/16 | 15,300 | 512,000 | 8,100 | 0.62 | 9 | 12 | 12.91 | 4 1/2 | 2 7/16 | 0.477 | 0.198 | 4 | |||

| 24,700 | 292,300 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 10,889 | 9,978 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 1.02 | 10 | 15.5 | 13.08 | 4 13/32 | 2 9/16 | 0.477 | 0.200 | 4 | |||

| 24,700 | 292,300 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 10,889 | 9,978 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 1.12 | 10 | 15 | 13.04 | 4 3/16 | 2 9/16 | 0.477 | 0.199 | 4 | |||

| 24,700 | 292,300 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 10,889 | 9,978 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 1.33 | 10 | 15 | 13.08 | 4 9/32 | 2 11/16 | 0.479 | 0.200 | 4 | |||

| 4 | 11.85 | Z-140 IU | 36,400 | 430,700 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 16,048 | 12,894 | HT38 | 4 3/4 | 2 7/16 | 28,400 | 708,100 | 17,000 | 0.78 | 10 | 15.5 | 13.45 | 4 9/16 | 2 5/16 | 0.473 | 0.206 | 4 |

| 36,400 | 430,700 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 16,048 | 12,894 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 0.76 | 10 | 15 | 13.04 | 4 15/32 | 2 9/16 | 0.477 | 0.199 | 4 | |||

| 36,400 | 430,700 | 0.262 | 3.476 | 3.077 | 2.700 | 5.400 | 16,048 | 12,894 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 0.90 | 10 | 15 | 13.08 | 4 17/32 | 2 11/16 | 0.479 | 0.200 | 4 | |||

| 4 | 14.00 | E-75 EU | 23,300 | 285,400 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 10,828 | 11,354 | NC46 | 6 | 3 1/4 | 33,600 | 901,200 | 17,600 | 1.44 | 9 | 12 | 16.51 | 5 9/32 | 3 1/8 | 0.453 | 0.253 | 4 |

| 4 | 14.00 | E-75 IU | 23,300 | 285,400 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 10,828 | 11,354 | NC40 | 5 1/4 | 2 13/16 | 23,500 | 711,600 | 12,400 | 1.01 | 9 | 12 | 15.64 | 4 13/16 | 2 11/16 | 0.445 | 0.239 | 4 |

| 23,300 | 285,400 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 10,828 | 11,354 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 1.09 | 10 | 15.5 | 15.28 | 4 3/8 | 2 9/16 | 0.442 | 0.234 | 4 | |||

| 23,300 | 285,400 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 10,828 | 11,354 | SH | 4 3/4 | 2 7/16 | 17,100 | 570,900 | 9,100 | 0.73 | 9 | 12 | 15.31 | 4 7/16 | 2 5/16 | 0.440 | 0.234 | 4 | |||

| 23,300 | 285,400 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 10,828 | 11,354 | HT40 | 5 1/4 | 2 13/16 | 31,900 | 711,600 | 19,100 | 1.37 | 9 | 15 | 15.93 | 4 19/32 | 2 11/16 | 0.444 | 0.244 | 4 | |||

| 23,300 | 285,400 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 10,828 | 11,354 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 1.19 | 10 | 15 | 15.25 | 4 5/32 | 2 9/16 | 0.442 | 0.233 | 4 | |||

| 23,300 | 285,400 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 10,828 | 11,354 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 1.41 | 10 | 15 | 15.29 | 4 1/4 | 2 11/16 | 0.444 | 0.234 | 4 | |||

| 4 | 14.00 | G-105 EU | 32,600 | 399,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 15,159 | 15,896 | NC46 | 6 | 3 1/4 | 33,600 | 901,200 | 17,600 | 1.03 | 9 | 12 | 16.51 | 5 7/16 | 3 1/8 | 0.453 | 0.253 | 4 |

| 4 | 14.00 | G-105 IU | 32,600 | 399,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 15,159 | 15,896 | NC40 | 5 1/2 | 2 7/16 | 30,100 | 897,200 | 15,600 | 0.92 | 9 | 12 | 16.62 | 5 | 2 5/16 | 0.439 | 0.254 | 4 |

| 32,600 | 399,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 15,159 | 15,896 | HT38 | 5 | 2 9/16 | 29,600 | 649,200 | 17,800 | 0.91 | 10 | 15.5 | 15.95 | 4 17/32 | 2 7/16 | 0.440 | 0.244 | 4 | |||

| 32,600 | 399,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 15,159 | 15,896 | SH | 4 3/4 | 2 7/16 | 17,100 | 570,900 | 9,100 | 0.52 | 9 | 12 | 15.31 | 4 21/32 | 2 5/16 | 0.440 | 0.234 | 4 | |||

| 32,600 | 399,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 15,159 | 15,896 | HT40 | 5 1/4 | 2 13/16 | 31,900 | 711,600 | 19,100 | 0.98 | 9 | 15 | 15.93 | 4 25/32 | 2 11/16 | 0.444 | 0.244 | 4 | |||

| 32,600 | 399,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 15,159 | 15,896 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 0.85 | 10 | 15 | 15.25 | 4 3/8 | 2 9/16 | 0.442 | 0.233 | 4 | |||

| 32,600 | 399,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 15,159 | 15,896 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 1.01 | 10 | 15 | 15.29 | 4 7/16 | 2 11/16 | 0.444 | 0.234 | 4 | |||

| 4 | 14.00 | S-135 EU | 41,900 | 513,600 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 19,491 | 20,141 | NC46 | 6 | 3 | 39,200 | 1,048,400 | 20,500 | 0.94 | 9 | 12 | 16.90 | 5 9/16 | 2 7/8 | 0.449 | 0.259 | 4 |

| 4 | 14.00 | S-135 IU | 41,900 | 513,600 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 19,491 | 20,141 | NC40 | 5 1/2 | 2 | 36,400 | 1,080,100 | 18,900 | 0.87 | 9 | 12 | 17.15 | 5 3/16 | 1 7/8 | 0.433 | 0.262 | 4 |

| 41,900 | 513,600 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 19,491 | 20,141 | HT38 | 5 | 2 7/16 | 33,000 | 708,100 | 19,800 | 0.79 | 10 | 15.5 | 16.13 | 4 11/16 | 2 5/16 | 0.438 | 0.247 | 4 | |||

| 41,900 | 513,600 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 19,491 | 20,141 | SH | 4 3/4 | 2 7/16 | 17,100 | 570,900 | 9,100 | 0.41 | 9 | 12 | 15.31 | NA | 2 5/16 | 0.440 | 0.234 | 4 | |||

| 41,900 | 513,600 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 19,491 | 20,141 | HT40 | 5 1/4 | 2 11/16 | 35,900 | 776,400 | 21,500 | 0.86 | 9 | 15 | 16.12 | 4 29/32 | 2 9/16 | 0.442 | 0.247 | 4 | |||

| 41,900 | 513,600 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 19,491 | 20,141 | XT38 | 4 3/4 | 2 9/16 | 31,300 | 599,600 | 18,800 | 0.75 | 10 | 15 | 15.44 | 4 17/32 | 2 7/16 | 0.440 | 0.236 | 4 | |||

| 41,900 | 513,600 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 19,491 | 20,141 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 0.88 | 10 | 15 | 15.67 | 4 17/32 | 2 7/16 | 0.440 | 0.240 | 4 | |||

| 41,900 | 513,600 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 19,491 | 20,141 | GPDS40 | 5 1/4 | 2 11/16 | 32,700 | 776,400 | 19,600 | 0.78 | 9 | 12 | 15.82 | 5 | 2 9/16 | 0.443 | 0.242 | 4 | |||

| 4 | 14.00 | V-150 IU | 46,600 | 570,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 21,656 | 21,912 | HT38 | 5 | 2 7/16 | 33,000 | 708,100 | 19,800 | 0.71 | 10 | 15.5 | 16.13 | 4 25/32 | 2 5/16 | 0.438 | 0.247 | 4 |

| 46,600 | 570,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 21,656 | 21,912 | HT40 | 5 1/4 | 2 11/16 | 35,900 | 776,400 | 21,500 | 0.77 | 9 | 15 | 16.12 | 5 | 2 9/16 | 0.442 | 0.247 | 4 | |||

| 46,600 | 570,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 21,656 | 21,912 | XT38 | 4 3/4 | 2 7/16 | 34,200 | 658,500 | 20,500 | 0.73 | 10 | 15 | 15.61 | 4 19/32 | 2 5/16 | 0.438 | 0.239 | 4 | |||

| 46,600 | 570,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 21,656 | 21,912 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 0.79 | 10 | 15 | 15.67 | 4 5/8 | 2 7/16 | 0.440 | 0.240 | 4 | |||

| 46,600 | 570,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 21,656 | 21,912 | GPDS40 | 5 1/4 | 2 9/16 | 36,400 | 838,300 | 21,800 | 0.78 | 9 | 12 | 15.99 | 5 1/32 | 2 7/16 | 0.441 | 0.245 | 4 | |||

| 4 | 14.00 | X-95 EU | 29,500 | 361,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 13,716 | 14,382 | NC46 | 6 | 3 1/4 | 33,600 | 901,200 | 17,600 | 1.14 | 9 | 12 | 16.51 | 5 3/8 | 3 1/8 | 0.453 | 0.253 | 4 |

| 4 | 14.00 | X-95 IU | 29,500 | 361,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 13,716 | 14,382 | NC40 | 5 1/4 | 2 11/16 | 25,700 | 776,400 | 13,500 | 0.87 | 9 | 12 | 15.82 | 4 15/16 | 2 9/16 | 0.443 | 0.242 | 4 |

| 29,500 | 361,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 13,716 | 14,382 | HT38 | 4 3/4 | 2 11/16 | 25,300 | 587,300 | 15,200 | 0.86 | 10 | 15.5 | 15.28 | 4 17/32 | 2 9/16 | 0.442 | 0.234 | 4 | |||

| 29,500 | 361,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 13,716 | 14,382 | SH | 4 3/4 | 2 7/16 | 17,100 | 570,900 | 9,100 | 0.58 | 9 | 12 | 15.31 | 4 19/32 | 2 5/16 | 0.440 | 0.234 | 4 | |||

| 29,500 | 361,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 13,716 | 14,382 | HT40 | 5 1/4 | 2 13/16 | 31,900 | 711,600 | 19,100 | 1.08 | 9 | 15 | 15.93 | 4 23/32 | 2 11/16 | 0.444 | 0.244 | 4 | |||

| 29,500 | 361,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 13,716 | 14,382 | XT38 | 4 3/4 | 2 11/16 | 27,700 | 537,800 | 16,600 | 0.94 | 10 | 15 | 15.25 | 4 5/16 | 2 9/16 | 0.442 | 0.233 | 4 | |||

| 29,500 | 361,500 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 13,716 | 14,382 | XT39 | 4 7/8 | 2 13/16 | 32,900 | 603,000 | 19,700 | 1.12 | 10 | 15 | 15.29 | 4 3/8 | 2 11/16 | 0.444 | 0.234 | 4 | |||

| 4 | 14.00 | Z-140 IU | 43,500 | 532,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 20,213 | 20,742 | HT38 | 5 | 2 7/16 | 33,000 | 708,100 | 19,800 | 0.76 | 10 | 15.5 | 16.13 | 4 23/32 | 2 5/16 | 0.438 | 0.247 | 4 |

| 43,500 | 532,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 20,213 | 20,742 | HT40 | 5 1/4 | 2 11/16 | 35,900 | 776,400 | 21,500 | 0.83 | 9 | 15 | 16.12 | 4 15/16 | 2 9/16 | 0.442 | 0.247 | 4 | |||

| 43,500 | 532,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 20,213 | 20,742 | XT38 | 4 3/4 | 2 9/16 | 31,300 | 599,600 | 18,800 | 0.72 | 10 | 15 | 15.44 | 4 9/16 | 2 7/16 | 0.440 | 0.236 | 4 | |||

| 43,500 | 532,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 20,213 | 20,742 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 0.85 | 10 | 15 | 15.67 | 4 9/16 | 2 7/16 | 0.440 | 0.240 | 4 | |||

| 43,500 | 532,700 | 0.330 | 3.340 | 3.805 | 3.229 | 6.458 | 20,213 | 20,742 | GPDS40 | 5 1/4 | 2 9/16 | 36,400 | 838,300 | 21,800 | 0.84 | 9 | 12 | 15.99 | 5 | 2 7/16 | 0.441 | 0.245 | 4 | |||

| 4 | 15.70 | E-75 EU | 25,800 | 324,100 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 12,469 | 12,896 | NC46 | 6 | 3 | 39,200 | 1,048,400 | 20,500 | 1.52 | 9 | 12 | 18.34 | 5 5/16 | 2 7/8 | 0.424 | 0.281 | 4 |

| 4 | 15.70 | E-75 IU | 25,800 | 324,100 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 12,469 | 12,896 | NC40 | 5 1/4 | 2 13/16 | 23,500 | 711,600 | 12,400 | 0.91 | 9 | 12 | 17.22 | 4 7/8 | 2 11/16 | 0.421 | 0.263 | 4 |

| 25,800 | 324,100 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 12,469 | 12,896 | HT40 | 5 1/4 | 2 13/16 | 31,900 | 711,600 | 19,100 | 1.24 | 9 | 15 | 17.49 | 4 5/8 | 2 11/16 | 0.420 | 0.268 | 4 | |||

| 25,800 | 324,100 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 12,469 | 12,896 | H90 | 5 1/2 | 2 13/16 | 35,400 | 913,700 | 20,400 | 1.37 | 9 | 12 | 17.67 | 4 31/32 | 2 11/16 | 0.420 | 0.270 | 4 | |||

| 25,800 | 324,100 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 12,469 | 12,896 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 1.43 | 10 | 15 | 17.24 | 4 5/32 | 2 7/16 | 0.415 | 0.264 | 4 | |||

| 25,800 | 324,100 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 12,469 | 12,896 | XT40 | 5 1/4 | 2 13/16 | 44,000 | 751,600 | 26,400 | 1.71 | 10 | 15 | 17.59 | 4 5/16 | 2 11/16 | 0.420 | 0.269 | 4 | |||

| 4 | 15.70 | G-105 EU | 36,100 | 453,800 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 17,456 | 18,055 | NC46 | 6 | 3 | 39,200 | 1,048,400 | 20,500 | 1.09 | 9 | 12 | 18.49 | 5 15/32 | 2 7/8 | 0.424 | 0.283 | 4 |

| 4 | 15.70 | G-105 IU | 36,100 | 453,800 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 17,456 | 18,055 | NC40 | 5 1/2 | 2 7/16 | 30,100 | 897,200 | 15,600 | 0.83 | 9 | 12 | 18.20 | 5 1/16 | 2 5/16 | 0.414 | 0.278 | 4 |

| 36,100 | 453,800 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 17,456 | 18,055 | HT40 | 5 1/4 | 2 13/16 | 31,900 | 711,600 | 19,100 | 0.88 | 9 | 15 | 17.49 | 4 27/32 | 2 11/16 | 0.420 | 0.268 | 4 | |||

| 36,100 | 453,800 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 17,456 | 18,055 | H90 | 5 1/2 | 2 13/16 | 35,400 | 913,700 | 20,400 | 0.98 | 9 | 15 | 18.00 | 5 5/32 | 2 11/16 | 0.420 | 0.275 | 4 | |||

| 36,100 | 453,800 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 17,456 | 18,055 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 1.02 | 10 | 15 | 17.24 | 4 13/32 | 2 7/16 | 0.415 | 0.264 | 4 | |||

| 36,100 | 453,800 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 17,456 | 18,055 | XT40 | 5 1/4 | 2 13/16 | 44,000 | 751,600 | 26,400 | 1.22 | 10 | 15 | 17.59 | 4 17/32 | 2 11/16 | 0.420 | 0.269 | 4 | |||

| 4 | 15.70 | S-135 EU | 46,500 | 583,400 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 22,444 | 23,213 | NC46 | 6 | 3 | 39,200 | 1,048,400 | 20,500 | 0.84 | 9 | 12 | 18.49 | 5 21/32 | 2 7/8 | 0.424 | 0.283 | 4 |

| 4 | 15.70 | S-135 IU | 46,500 | 583,400 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 22,444 | 23,213 | NC40 | 5 1/2 | 2 | 36,400 | 1,080,100 | 18,900 | 0.78 | 9 | 12 | 18.73 | 5 1/4 | 1 7/8 | 0.409 | 0.286 | 4 |

| 46,500 | 583,400 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 22,444 | 23,213 | HT40 | 5 1/4 | 2 9/16 | 39,500 | 838,300 | 23,700 | 0.85 | 9 | 15 | 17.88 | 4 15/16 | 2 7/16 | 0.415 | 0.273 | 4 | |||

| 46,500 | 583,400 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 22,444 | 23,213 | H90 | 5 3/4 | 2 11/16 | 38,400 | 978,500 | 21,800 | 0.83 | 9 | 15 | 18.74 | 5 5/16 | 2 9/16 | 0.417 | 0.287 | 4 | |||

| 46,500 | 583,400 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 22,444 | 23,213 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 0.80 | 10 | 15 | 17.24 | 4 5/8 | 2 7/16 | 0.415 | 0.264 | 4 | |||

| 46,500 | 583,400 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 22,444 | 23,213 | XT40 | 5 1/4 | 2 13/16 | 44,000 | 751,600 | 26,400 | 0.95 | 10 | 15 | 17.59 | 4 3/4 | 2 11/16 | 0.420 | 0.269 | 4 | |||

| 46,500 | 583,400 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 22,444 | 23,213 | GPDS40 | 5 1/4 | 2 9/16 | 36,400 | 838,300 | 21,800 | 0.78 | 9 | 12 | 17.57 | 5 1/32 | 2 7/16 | 0.417 | 0.269 | 4 | |||

| 4 | 15.70 | V-150 IU | 51,600 | 648,200 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 24,938 | 25,793 | HT40 | 5 1/4 | 2 7/16 | 41,000 | 897,200 | 24,600 | 0.79 | 9 | 15 | 18.05 | 5 | 2 5/16 | 0.413 | 0.276 | 4 |

| 51,600 | 648,200 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 24,938 | 25,793 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 0.72 | 10 | 15 | 17.24 | 4 23/32 | 2 7/16 | 0.415 | 0.264 | 4 | |||

| 51,600 | 648,200 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 24,938 | 25,793 | XT40 | 5 1/4 | 2 11/16 | 48,100 | 816,400 | 28,900 | 0.93 | 10 | 15 | 17.79 | 4 25/32 | 2 9/16 | 0.417 | 0.272 | 4 | |||

| 51,600 | 648,200 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 24,938 | 25,793 | GPDS40 | 5 1/4 | 2 7/16 | 38,100 | 897,200 | 22,900 | 0.74 | 9 | 12 | 17.74 | 5 3/32 | 2 5/16 | 0.415 | 0.271 | 4 | |||

| 4 | 15.70 | X-95 EU | 32,700 | 410,500 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 15,794 | 16,335 | NC46 | 6 | 3 | 39,200 | 1,048,400 | 20,500 | 1.20 | 9 | 12 | 18.49 | 5 7/16 | 2 7/8 | 0.424 | 0.283 | 4 |

| 4 | 15.70 | X-95 IU | 32,700 | 410,500 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 15,794 | 16,335 | NC40 | 5 1/4 | 2 9/16 | 27,800 | 838,300 | 14,600 | 0.85 | 9 | 12 | 17.57 | 5 | 2 7/16 | 0.417 | 0.269 | 4 |

| 32,700 | 410,500 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 15,794 | 16,335 | HT40 | 5 1/4 | 2 13/16 | 31,900 | 711,600 | 19,100 | 0.98 | 9 | 15 | 17.49 | 4 25/32 | 2 11/16 | 0.420 | 0.268 | 4 | |||

| 32,700 | 410,500 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 15,794 | 16,335 | H90 | 5 1/2 | 2 13/16 | 35,400 | 913,700 | 20,400 | 1.08 | 9 | 12 | 17.67 | 5 3/32 | 2 11/16 | 0.420 | 0.270 | 4 | |||

| 32,700 | 410,500 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 15,794 | 16,335 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 1.13 | 10 | 15 | 17.24 | 4 5/16 | 2 7/16 | 0.415 | 0.264 | 4 | |||

| 32,700 | 410,500 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 15,794 | 16,335 | XT40 | 5 1/4 | 2 13/16 | 44,000 | 751,600 | 26,400 | 1.35 | 10 | 15 | 17.59 | 4 15/32 | 2 11/16 | 0.420 | 0.269 | 4 | |||

| 4 | 15.70 | Z-140 IU | 48,200 | 605,000 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 23,275 | 24,073 | HT40 | 5 1/4 | 2 9/16 | 39,500 | 838,300 | 23,700 | 0.82 | 9 | 15 | 17.88 | 4 31/32 | 2 7/16 | 0.415 | 0.273 | 4 |

| 48,200 | 605,000 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 23,275 | 24,073 | XT39 | 4 7/8 | 2 9/16 | 37,000 | 729,700 | 22,200 | 0.77 | 10 | 15 | 17.24 | 4 21/32 | 2 7/16 | 0.415 | 0.264 | 4 | |||

| 48,200 | 605,000 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 23,275 | 24,073 | XT40 | 5 1/4 | 2 13/16 | 44,000 | 751,600 | 26,400 | 0.91 | 10 | 15 | 17.59 | 4 25/32 | 2 11/16 | 0.420 | 0.269 | 4 | |||

| 48,200 | 605,000 | 0.380 | 3.240 | 4.322 | 3.578 | 7.157 | 23,275 | 24,073 | GPDS40 | 5 1/4 | 2 9/16 | 36,400 | 838,300 | 21,800 | 0.76 | 9 | 12 | 17.57 | 5 1/16 | 2 7/16 | 0.417 | 0.269 | 4 | |||

4.5″ Drill Pipe API Specs

| Pipe Data | Tool Joint Data | Assembly Data | ||||||||||||||||||||||||

| Size Outer D | Nominal Weight | Grade and UpsetType | Torsional Yield Strength | Tensile Yield Strength | Wall Thickness | Nominal ID | Pipe Body Section Area | Pipe Body Section Modulus | Pipe Body Polar Section Modulus | Internal Pressure | Collapse Pressure | Connection Type | Outside Diameter | Inside Diameter | Torsional Yield Strength | Tensile Yield Strength | Make-up Torque | Torsional Ratio Tool Joint to Pipe | * Pin Tong Space | * Box Tong Space | Adjusted Weight | Minimum Tool Joint O.D. for Prem. Class | Drift Diameter | Capacity | Displace- ment | Size Outer D |

| 4 1/2 | 16.60 | E-75 EU | 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | OH | 5 7/8 | 3 3/4 | 27,300 | 714,000 | 14,600 | 0.89 | 9 | 12 | 17.58 | 5 15/32 | 3 5/8 | 0.596 | 0.269 | 4 1/2 |

| 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | NC50 | 6 5/8 | 3 3/4 | 38,100 | 939,100 | 19,800 | 1.24 | 9 | 12 | 19.19 | 5 23/32 | 3 5/8 | 0.595 | 0.294 | 4 1/2 | |||

| 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | HT50 | 6 1/4 | 3 3/4 | 52,700 | 939,100 | 31,600 | 1.71 | 9 | 15 | 18.73 | 5 13/16 | 3 5/8 | 0.595 | 0.287 | 4 1/2 | |||

| 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | XT50 | 6 3/8 | 3 3/4 | 75,200 | 1,085,500 | 45,100 | 2.44 | 10 | 15 | 19.17 | 5 31/32 | 3 5/8 | 0.595 | 0.293 | 4 1/2 | |||

| 4 1/2 | 16.60 | E-75 IEU | 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | NC46 | 6 1/4 | 3 1/4 | 34,000 | 901,200 | 17,600 | 1.10 | 9 | 12 | 19.14 | 5 13/32 | 3 1/8 | 0.585 | 0.293 | 4 1/2 |

| 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | FH | 6 | 3 | 34,800 | 976,200 | 17,600 | 1.13 | 9 | 12 | 19.03 | 5 3/8 | 2 7/8 | 0.580 | 0.291 | 4 1/2 | |||

| 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | H90 | 6 | 3 1/4 | 39,000 | 938,400 | 18,800 | 1.27 | 9 | 12 | 18.61 | 5 11/32 | 3 1/8 | 0.585 | 0.285 | 4 1/2 | |||

| 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | HT46 | 6 1/4 | 3 1/4 | 47,600 | 901,200 | 28,600 | 1.55 | 9 | 15 | 19.59 | 5 13/32 | 3 1/8 | 0.583 | 0.300 | 4 1/2 | |||

| 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | XT40 | 5 1/4 | 3 | 37,400 | 648,900 | 22,400 | 1.21 | 10 | 15 | 17.92 | 4 7/8 | 2 7/8 | 0.579 | 0.274 | 4 1/2 | |||

| 30,800 | 330,600 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 9,829 | 10,392 | XT46 | 6 | 3 1/2 | 58,100 | 910,300 | 34,900 | 1.89 | 10 | 15 | 18.63 | 5 5/8 | 3 3/8 | 0.589 | 0.285 | 4 1/2 | |||

| 4 1/2 | 16.60 | G-105 EU | 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | OH | 6 | 3 1/4 | 40,300 | 1,043,800 | 21,500 | 0.94 | 9 | 12 | 18.69 | 5 21/32 | 3 1/8 | 0.585 | 0.286 | 4 1/2 |

| 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | NC50 | 6 5/8 | 3 3/4 | 38,100 | 939,100 | 19,800 | 0.88 | 9 | 12 | 19.19 | 5 29/32 | 3 5/8 | 0.595 | 0.294 | 4 1/2 | |||

| 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | HT50 | 6 1/4 | 3 3/4 | 52,700 | 939,100 | 31,600 | 1.22 | 9 | 15 | 18.73 | 5 13/16 | 3 5/8 | 0.595 | 0.287 | 4 1/2 | |||

| 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | XT50 | 6 3/8 | 3 3/4 | 75,200 | 1,085,500 | 45,100 | 1.74 | 10 | 15 | 19.17 | 5 31/32 | 3 5/8 | 0.595 | 0.293 | 4 1/2 | |||

| 4 1/2 | 16.60 | G-105 IEU | 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | NC46 | 6 1/4 | 3 | 39,700 | 1,048,400 | 20,500 | 0.92 | 9 | 12 | 19.57 | 5 19/32 | 2 7/8 | 0.580 | 0.299 | 4 1/2 |

| 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | FH | 6 1/4 | 2 3/4 | 40,200 | 1,111,600 | 20,100 | 0.93 | 9 | 12 | 19.96 | 5 9/16 | 2 5/8 | 0.575 | 0.305 | 4 1/2 | |||

| 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | H90 | 6 | 3 1/4 | 39,000 | 938,400 | 18,800 | 0.90 | 9 | 12 | 18.61 | 5 17/32 | 3 1/8 | 0.585 | 0.285 | 4 1/2 | |||

| 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | HT46 | 6 1/4 | 3 1/4 | 47,600 | 901,200 | 28,600 | 1.10 | 9 | 15 | 19.59 | 5 13/32 | 3 1/8 | 0.583 | 0.300 | 4 1/2 | |||

| 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | XT40 | 5 1/4 | 3 | 37,400 | 648,900 | 22,400 | 0.87 | 10 | 15 | 17.92 | 4 7/8 | 2 7/8 | 0.579 | 0.274 | 4 1/2 | |||

| 43,100 | 462,800 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 13,761 | 13,825 | XT46 | 6 | 3 1/2 | 58,100 | 910,300 | 34,900 | 1.35 | 10 | 15 | 18.63 | 5 5/8 | 3 3/8 | 0.589 | 0.285 | 4 1/2 | |||

| 4 1/2 | 16.60 | S-135 EU | 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | OH | 6 | 3 | 43,400 | 1,191,100 | 24,600 | 0.78 | 9 | 12 | 19.07 | 5 13/16 | 2 7/8 | 0.581 | 0.292 | 4 1/2 |

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | NC50 | 6 5/8 | 3 1/2 | 45,100 | 1,109,900 | 23,400 | 0.81 | 9 | 12 | 19.65 | 6 1/16 | 3 3/8 | 0.590 | 0.301 | 4 1/2 | |||

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | HT50 | 6 3/8 | 3 1/2 | 65,700 | 1,109,900 | 39,400 | 1.18 | 9 | 15 | 19.52 | 5 13/16 | 3 3/8 | 0.589 | 0.299 | 4 1/2 | |||

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | XT50 | 6 3/8 | 3 3/4 | 75,200 | 1,085,500 | 45,100 | 1.35 | 10 | 15 | 19.17 | 5 31/32 | 3 5/8 | 0.595 | 0.293 | 4 1/2 | |||

| 4 1/2 | 16.60 | S-135 IEU | 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | NC46 | 6 1/4 | 2 3/4 | 44,900 | 1,183,900 | 23,200 | 0.81 | 9 | 12 | 19.96 | 5 25/32 | 2 5/8 | 0.575 | 0.305 | 4 1/2 |

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | FH | 6 1/4 | 2 3/4 | 40,200 | 1,111,600 | 20,100 | 0.72 | 9 | 12 | 19.96 | 5 3/4 | 2 5/8 | 0.575 | 0.305 | 4 1/2 | |||

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | H90 | 6 1/4 | 2 3/4 | 51,500 | 1,221,100 | 24,600 | 0.93 | 9 | 12 | 19.96 | 5 11/16 | 2 5/8 | 0.575 | 0.305 | 4 1/2 | |||

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | HT46 | 6 1/4 | 3 1/4 | 47,600 | 901,200 | 28,600 | 0.86 | 9 | 15 | 19.59 | 5 1/2 | 3 1/8 | 0.583 | 0.300 | 4 1/2 | |||

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | XT40 | 5 1/4 | 2 13/16 | 44,000 | 751,600 | 26,400 | 0.79 | 10 | 15 | 18.23 | 4 15/16 | 2 11/16 | 0.575 | 0.279 | 4 1/2 | |||

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | XT46 | 6 | 3 1/2 | 58,100 | 910,300 | 34,900 | 1.05 | 10 | 15 | 18.63 | 5 5/8 | 3 3/8 | 0.589 | 0.285 | 4 1/2 | |||

| 55,500 | 595,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 17,693 | 16,773 | GPDS46 | 6 1/4 | 3 1/4 | 43,300 | 901,200 | 26,000 | 0.78 | 9 | 12 | 19.14 | 5 19/32 | 3 1/8 | 0.585 | 0.293 | 4 1/2 | |||

| 4 1/2 | 16.60 | V-150 EU | 61,600 | 661,100 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 19,658 | 18,103 | HT50 | 6 3/8 | 3 1/2 | 65,700 | 1,109,900 | 39,400 | 1.07 | 9 | 15 | 19.52 | 5 13/16 | 3 3/8 | 0.589 | 0.299 | 4 1/2 |

| 61,600 | 661,100 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 19,658 | 18,103 | XT50 | 6 3/8 | 3 1/2 | 81,200 | 1,256,300 | 48,700 | 1.32 | 10 | 15 | 19.67 | 5 31/32 | 3 3/8 | 0.589 | 0.301 | 4 1/2 | |||

| 4 1/2 | 16.60 | V-150 IEU | 61,600 | 661,100 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 19,658 | 18,103 | HT46 | 6 1/4 | 3 1/4 | 47,600 | 901,200 | 28,600 | 0.77 | 9 | 15 | 19.59 | 5 19/32 | 3 1/8 | 0.583 | 0.300 | 4 1/2 |

| 61,600 | 661,100 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 19,658 | 18,103 | XT40 | 5 1/4 | 2 13/16 | 44,000 | 751,600 | 26,400 | 0.71 | 10 | 15 | 18.23 | 5 1/16 | 2 11/16 | 0.575 | 0.279 | 4 1/2 | |||

| 61,600 | 661,100 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 19,658 | 18,103 | XT46 | 6 1/4 | 3 1/4 | 70,200 | 1,069,300 | 42,100 | 1.14 | 10 | 15 | 19.74 | 5 5/8 | 3 1/8 | 0.583 | 0.302 | 4 1/2 | |||

| 61,600 | 661,100 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 19,658 | 18,103 | GPDS46 | 6 1/4 | 3 1/4 | 43,300 | 901,200 | 26,000 | 0.70 | 9 | 12 | 19.14 | 5 11/16 | 3 1/8 | 0.585 | 0.293 | 4 1/2 | |||

| 4 1/2 | 16.60 | X-95 EU | 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | OH | 5 7/8 | 3 1/2 | 33,900 | 884,800 | 18,200 | 0.87 | 9 | 12 | 18.02 | 5 19/32 | 3 3/8 | 0.590 | 0.276 | 4 1/2 |

| 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | NC50 | 6 5/8 | 3 3/4 | 38,100 | 939,100 | 19,800 | 0.98 | 9 | 12 | 19.19 | 5 27/32 | 3 5/8 | 0.595 | 0.294 | 4 1/2 | |||

| 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | HT50 | 6 1/4 | 3 3/4 | 52,700 | 939,100 | 31,600 | 1.35 | 9 | 15 | 18.73 | 5 13/16 | 3 5/8 | 0.595 | 0.287 | 4 1/2 | |||

| 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | XT50 | 6 3/8 | 3 3/4 | 75,200 | 1,085,500 | 45,100 | 1.93 | 10 | 15 | 19.17 | 5 31/32 | 3 5/8 | 0.595 | 0.293 | 4 1/2 | |||

| 4 1/2 | 16.60 | X-95 IEU | 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | NC46 | 6 1/4 | 3 1/4 | 34,000 | 901,200 | 17,600 | 0.87 | 9 | 12 | 19.14 | 5 17/32 | 3 1/8 | 0.585 | 0.293 | 4 1/2 |

| 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | FH | 6 | 3 | 34,800 | 976,200 | 17,600 | 0.89 | 9 | 12 | 19.03 | 5 1/2 | 2 7/8 | 0.580 | 0.291 | 4 1/2 | |||

| 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | H90 | 6 | 3 1/4 | 39,000 | 938,400 | 18,800 | 1.00 | 9 | 12 | 18.61 | 5 15/32 | 3 1/8 | 0.585 | 0.285 | 4 1/2 | |||

| 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | HT46 | 6 1/4 | 3 1/4 | 47,600 | 901,200 | 28,600 | 1.22 | 9 | 15 | 19.59 | 5 13/32 | 3 1/8 | 0.583 | 0.300 | 4 1/2 | |||

| 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | XT40 | 5 1/4 | 3 | 37,400 | 648,900 | 22,400 | 0.96 | 10 | 15 | 17.92 | 4 7/8 | 2 7/8 | 0.579 | 0.274 | 4 1/2 | |||

| 39,000 | 418,700 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 12,450 | 12,765 | XT46 | 6 | 3 1/2 | 58,100 | 910,300 | 34,900 | 1.49 | 10 | 15 | 18.63 | 5 5/8 | 3 3/8 | 0.589 | 0.285 | 4 1/2 | |||

| 4 1/2 | 16.60 | Z-140 EU | 57,500 | 617,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 18,348 | 17,228 | HT50 | 6 3/8 | 3 1/2 | 65,700 | 1,109,900 | 39,400 | 1.14 | 9 | 15 | 19.52 | 5 13/16 | 3 3/8 | 0.589 | 0.299 | 4 1/2 |

| 57,500 | 617,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 18,348 | 17,228 | XT50 | 6 3/8 | 3 3/4 | 75,200 | 1,085,500 | 45,100 | 1.31 | 10 | 15 | 19.17 | 5 31/32 | 3 5/8 | 0.595 | 0.293 | 4 1/2 | |||

| 4 1/2 | 16.60 | Z-140 IEU | 57,500 | 617,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 18,348 | 17,228 | HT46 | 6 1/4 | 3 1/4 | 47,600 | 901,200 | 28,600 | 0.83 | 9 | 15 | 19.59 | 5 17/32 | 3 1/8 | 0.583 | 0.300 | 4 1/2 |

| 57,500 | 617,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 18,348 | 17,228 | XT40 | 5 1/4 | 2 13/16 | 44,000 | 751,600 | 26,400 | 0.77 | 10 | 15 | 18.23 | 4 31/32 | 2 11/16 | 0.575 | 0.279 | 4 1/2 | |||

| 57,500 | 617,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 18,348 | 17,228 | XT46 | 6 | 3 1/2 | 58,100 | 910,300 | 34,900 | 1.01 | 10 | 15 | 18.63 | 5 5/8 | 3 3/8 | 0.589 | 0.285 | 4 1/2 | |||

| 57,500 | 617,000 | 0.337 | 3.826 | 4.407 | 4.271 | 8.543 | 18,348 | 17,228 | GPDS46 | 6 1/4 | 3 1/4 | 43,300 | 901,200 | 26,000 | 0.75 | 9 | 12 | 19.14 | 5 5/8 | 3 1/8 | 0.585 | 0.293 | 4 1/2 | |||

| 4 1/2 | 20.00 | E-75 EU | 36,900 | 412,400 | 0.430 | 3.640 | 5.498 | 5.116 | 10.232 | 12,542 | 12,964 | OH | 6 | 3 1/2 | 34,100 | 884,800 | 18,200 | 0.92 | 9 | 12 | 21.64 | 5 17/32 | 3 3/8 | 0.538 | 0.331 | 4 1/2 |

| 36,900 | 412,400 | 0.430 | 3.640 | 5.498 | 5.116 | 10.232 | 12,542 | 12,964 | NC50 | 6 5/8 | 3 5/8 | 41,700 | 1,026,000 | 21,600 | 1.13 | 9 | 12 | 22.77 | 5 13/16 | 3 1/2 | 0.540 | 0.348 | 4 1/2 | |||