In California, barite was first used in a well being redrilled with cable tools in 1923. According to the report, the density of the mud was raised to 90 lb/ft3 (1.44 g/cm3 ) to control the gas inflow and to stop caving. Here in this article, we will discuss the major knowledge that drilling engineers & mud engineers should know about Barite in drilling mud / fluid & its weight up formula. (Check also: Barite Sag Problem indications & prevention)

Barite Application In Drilling Mud

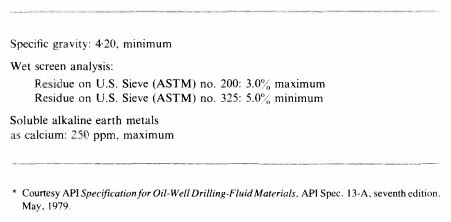

Barite (barium sulfate, BaSO4) contains 58.8 % barium and has a specific gravity of (4.2–4.5). The barite used in drilling fluid, which is normally impure, is of lower specific gravity as it contains other minerals such as quartz, chert, calcite, anhydrite, celestite, and various silicates. Also, it consists of other iron minerals, some of which may increase the average specific gravity of the product. Barite physically is not soluble in water and does not cause any chemical reactions with other drilling mud chemicals.

In general, barite is used for raising the density of water-based mud and oil-based drilling fluids up to 22 ppg (2.64 sg). Barite is also used for weighting up kill fluids, and in the Barite lock plug formulation.

Barite Physical Properties

The barite is an inert solid weighting agent that does not react with mud additives or drilled contaminants.

- Appearance: Powder

- Colour: Light Tan/Pink/Grey

- Odor: None

- Specific Gravity: 4.20 to 4.27

- Molecular Weight (g/mole): 233.4

- Flash Point: 1,580°C

- Solubility: Insoluble in water

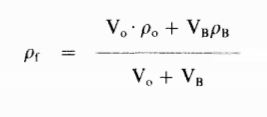

Barite Weight Up Formula

One other function of barite has developed the preparation of a temporary high-density plug formed from a slurry of barite in water (2.65 SG). Such a slurry contains the maximum concentration of barite that is used—about 750 Ib/bbl (2100 kg/m3 ). The minimum concentration of barite might be as low as 10 Ib/bbl (28 kg/m3 ), although usually, it would be substantially higher. The quantity of barite required to raise the density of a given volume of mud a specific amount can be readily calculated from the relation, in consistent units:

Where:

- ρf = final mud density

- ρo = original mud density

- ρR = barite density

- Vo = original mud volume

- VB = barite volume

HSE Notes While Mixing Barite In Drilling Mud

Barite can be hazardous to health and should not be ingested (Oil Rig Hazards). The following safety wear should be used when mixing Barite:

- Standard PPE

- Dust Mask

Caution:

- Drilling mud barite may cause eye, skin, and respiratory irritation. May be harmful if swallowed.

- Breathing crystalline silica can cause lung disease, including silicosis and lung cancer. Crystalline silica has also been associated with scleroderma and kidney disease.

First Aid Measures:

- Inhalation: If inhaled, remove from area to fresh air. Get medical attention if respiratory irritation develops or if breathing becomes difficult.

- Skin: Wash with soap and water. Get medical attention if irritation persists.

- Eyes: In case of drilling mud barite contact, immediately flush eyes with plenty of water for at least 15 minutes and get medical attention if irritation persists.

- Ingestion: Do not induce vomiting. Slowly dilute with 1-2 glasses of water or milk and seek medical attention. Never give anything by mouth to an unconscious person.

Handling Precautions

- Drilling fluid barite contains quartz, cristobalite, and/or tridymite which may become airborne without a visible cloud.

- Avoid breathing the dust of drilling mud barite.

- Avoid creating dusty conditions.

- Use only with adequate ventilation to keep exposure below recommended exposure limits.

- Wear a NIOSH-certified, European Standard En 149, or equivalent respirator when using this product.

- Material is slippery when wet.

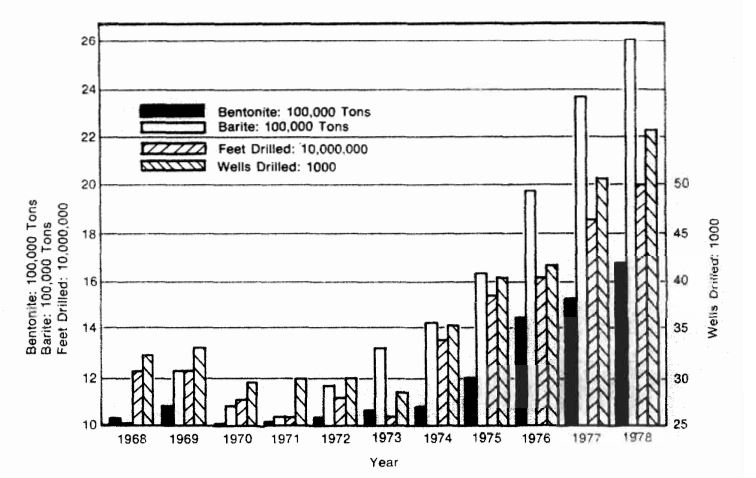

Barite Consumption Through Years

The quantity of drilling mud barite consumed annually has increased each year since 1971, as shown in Fig. 2, Also shown in the figure are the number of wells and the total number of feet drilled each year from 1968 through 1978. A rough correlation is evident between barite consumption, number of wells, and total footage drilled, although the barite usage over the interval has increased more than might be anticipated from the drilling record.

Rogers noted a similar rough correlation for the period 1938-1962. The average amount of barite used per 1,000 feet of the hole has increased from 5.4 tons for the interval 1953-1962 to 9.2 tons for the period 1969-1978. Present barite consumption is about 11 tons per 1,000 feet of the hole. Barite consumption is affected by the magnitude of the pressure to be controlled, the volume of mud in use (as determined by hole diameter and depth), and the time spent in drilling. Other factors which affect requirements are the effectiveness of cutting-separation and the reuse of weighted muds.

Consumption of barite is significantly reduced by the use of centrifuges and by the reconditioning and reuse of heavy drilling muds, although no estimate can be made of the quantity thus saved. About 2,620,000 tons (2,380,000 tonnes) of barite, having a well-site cost of roughly $350,000,000 (check also oil well drilling well cost per foot), was used in drilling in 1978. Further increase in U.S. barite consumption is forecast, with use in drilling (90% of the total) amounting to 3.7 million tons in 1983.

Ref: Barite datasheet from Baroid, composition & properties of drilling and completion fluids, https://link.springer.com/article/10.1007/s13202-016-0258-2