Working on oil and gas rigs has several hazards that drilling engineers should know. In this article, we shall divide any drilling rig type into specific zones, and we will explain the dangers & safety tips at each zone.

We will introduce the following five zones below:

- On the rig floor (Drilling Rig Components)

- Around pipe racks

- Around drilling fluid tanks

- In the cellar

- Around the location

HAZARDS ON THE OIL DRILLING RIG FLOOR

Setting back drill-pipe

Similarly, you may find yourself helping to stack drill pipe by pushing a stand across the rig floor (Rig Floor Inspection Procedure) while hanging from the hook in the derrick. As the pipe moves away from you, don’t take such long steps that your foot gets underneath it.

Remember that suspended loads have a habit of dropping, sometimes without warning. This is one of the most common themes which run through safety awareness training.

Stabbing drill pipe

You will probably not be asked to help run drill string into the hole, but if you should act as a floorman, remember that a golden rule is never to put a hand on the pipe already in the hole. The driller may lower the additional pipe when you don’t expect it.

In earlier generations, roughnecks were well paid but not given much safety training. Most finished with more gold rings than their fingers left to put on.

Trip hazards in oil rigs

The derrick floor (or any other working area) should be clean and tidy, but occasionally, it may become cluttered with equipment and tools. Watch where you walk – if you trip, there are not too many things on a rig floor that you can safely get hold of to steady yourself.

Trips on stairs can be a hazard in oil rigs. Always have one hand available for the railing – especially on a floating unit. We should move anything too heavy or bulky to be carried in one hand between different levels by winch.

High pressures

Hoses and pipe connections occasionally fail when high pressures are used during pressure testing or pumping operations such as cementing or formation stimulation. A small leak may result in a fine jet of high-pressure liquid that can cut and penetrate soft material.

If a hose or pipe fails during a high-pressure operation, the broken connection will flail violently until the pump operator has had time to react. You will notice that during a high-pressure operation, the lines and hoses will be chained to a fixed part of the rig structure or a stake hammered into the ground. This restrain movement in case of failure is not always 100% effective.

Avoid these two oil rig hazards by keeping your distance from high-pressure lines, especially while pumping or testing.

Core recovery

Coring is always enjoyable; you may be impatient to see whether a good core has been recovered. Avoid putting your fingers into the bottom of the core barrel while hanging an inch above the floor.

The core barrel is a suspended load and the core inside it may be supported only by friction and may slide out at the wrong moment.

Wire rope to backup tongs

When the drilling crew is running pipe in or out of the hole, they tighten or loosen the connections using tongs operated by wire ropes. One wire goes to the drawworks and pulls; the other goes from the so-called backup tongs to a fixed point on the rig floor to stop the other half of the connection from turning. When the driller tightens the pulling cable, the backup tong will suddenly rotate a quarter of a turn around the pipe, and the wireline that was lying loose will snap tight. Anyone standing too close to this cable could then be seriously hurt.

If you go on the rig floor during tripping pipe or while running casing, approach it from the driller’s side and stand behind him until you are sure you know how everything there is moving.

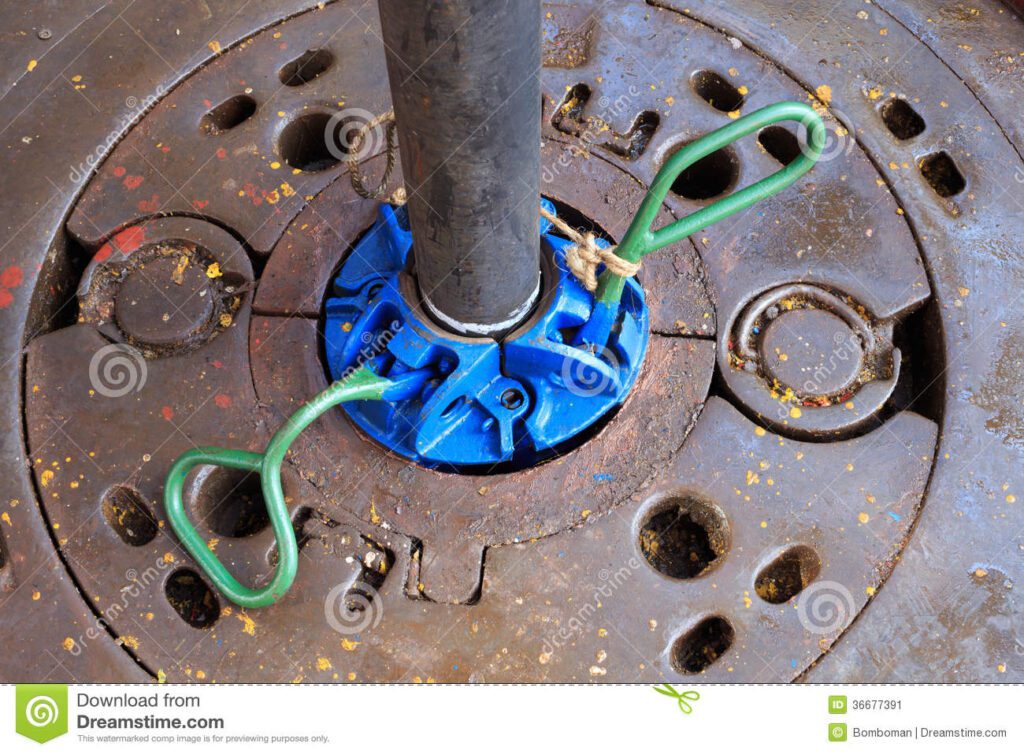

Rotary table

It may seem obvious, but the rotary table can rotate and is a particular trip hazard in oil rigs. If you walk across the derrick floor, walk around the rotary table, even if it is not moving as you approach it.

Drilling fluid sprays

The tongs are not the only hazard when pulling the drill pipe out. Remember that a column of drilling fluid types may be almost 30 meters high inside the pipe. As the connection has unscrewed, this liquid (commonly with a pH of 10 or 11) may spurt out into the eyes of the unwary spectator.

Tubulars hazards are being lifted through the V-door in oil rigs.

When drilling, running casing, or running production tubing, single pipe joints will be lifted from the pipe racks, through the V-door, and into the derrick. If the driller lifts one just a little too quickly, the end will come up the ramp, over the edge of the floor, and the whole pipe will swing violently across the floor. Don’t put yourself in a position where it could hit you.

Wireline being run into the hole.

From time to time, tools run into the hole in the wireline. If a tool is being run quickly and meets resistance of some sort in the hole, the winch operator may not be able to stop quickly enough. In that case, the wire will continue spooling off the drum and fall onto the derrick floor in loops. When the tool in the hole falls free an instant later, the loose wire will be dragged very quickly into the hole, and the loops will snap tight with enough force to sever a limb. Keep a safe distance away during this operation.

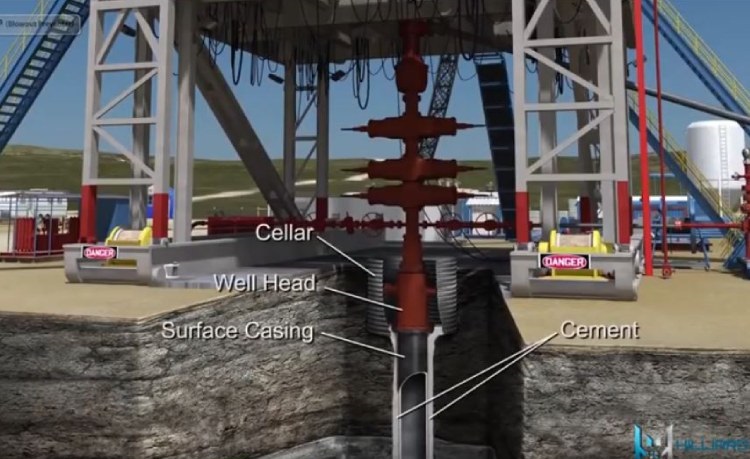

HAZARDS IN THE OIL RIGS CELLAR

A well is rarely drilled without any gas indications; thus, there is always the possibility of gas coming out of the solution from the drilling fluid. Most hydrocarbon gases are heavier than air and, therefore, tend to gather at the lowest point in a location, generally in the cellar. Do not be tempted to climb alone into a deep cellar on a land location to look at the equipment or check the gauges – there may not be enough oxygen there to support life. If there also happens to be H2S present, you may not stay alive for long enough for someone to get a line around you and lift you out, even if they see you collapse!

A gas test will be made when enclosed and unventilated spaces, including the cellar, are entered for operational reasons. The “buddy” system will be used with one crew member remaining outside the space.

HAZARDS ON AND AROUND THE PIPE RACKS IN OIL RIGS

Singles are being laid down.

The hazard of lifting single joints into the oil rig derrick has been mentioned. The opposite operation – laying down pipe – allows a pipe joint to slide freely down the ramp and along the catwalk. In doing so, it acquires a large amount of kinetic energy, which a sprung barrier at the end of the catwalk should absorb. Occasionally, a joint will jump over the barrier or slide down the ramp off-center and go sideways off the catwalk. Don’t put yourself into a position where one of these could hit you.

Standing on tubulars

One of the jobs that oil and gas companies may give you as a trainee is to measure the casing while it is laid out on the pipe racks. Before you walk on the casing, which you will have to do, ensure that the joints are tightly packed and that the first and last are firmly wedged in place so they do not roll as you step on them.

HAZARDS AROUND THE OIL DRILLING RIG FLUID TANKS

The low-pressure drilling fluid system has its share of hazards for the unwary. Derrickmen shall take care of a lot as they work with drilling fluid systems (including the shale shakers, circulating system, etc.) more than others.

Drilling fluid has, by design, lubricating qualities. Any minor spills, drips, etc., or spray blown by a strong wind may cause stairs and walkways to become slippery. This is especially the case near the drilling fluid mixing area, where the wind may pick up powder as sacks are emptied into the mixing hopper.

Dust around the mixing area in oil rigs is also unpleasant for the eyes, but this is an obvious hazard. With one exception, drilling fluid products are relatively innocuous – designed to be environmentally friendly – but cement dust is not. If sacks of cement are being cut open and emptied, either into the bulk tanks or while mixing cement slurry, the dust that may be blown around has a high pH and is terrible for the eyes and lungs.

Caustic Soda

The one exception mentioned in the previous paragraph is caustic soda, delivered as beads or crystals in metal drums. These solids will go through leather gloves and leather boots in no time!

Caustic soda is used because many water-based drilling fluid systems require a high pH of 10 or 11. Even though it may not cause immediate caustic burns, a high-pH liquid still harms the skin. Don’t put your hands into the drilling fluid. If you are splashed, wash it off, and if your clothes become wet with drilling fluid, change them.

There will be eye-wash stations at various locations on the drilling unit, specifically near the drilling fluid mixing area. It is probably a good idea to try it to see how it works while you can still see what you are doing clearly, but check with someone in authority first, as some systems are designed for one-time use only.

HAZARDS AROUND THE OIL DRILLING RIG LOCATION

Cranes

Cranes lift relatively distant heavy loads into the air and swing around to move them over intervening obstructions. The resulting hazard is that a load may pass over people in the oil rig without them being aware. If a crane is working on location, ensure you remain aware of what it is doing.

You will know by now that you should not be under a suspended load. In addition, you might not realize that you should not be close to the crane or under the jib. Cranes occasionally fall over, and jibs occasionally fail. In theory, automatic safeguards prevent safe working loads from being exceeded; in practice, it still happens.

Even if you are not underneath the load, keep clear of the area where loads are being picked or set. This is because they can swing unexpectedly – especially offshore rigs.

Moving vehicles, including forklifts

Trucks, cranes, and forklifts are fitted with reversing alarms. This is done for a good reason. If you can hear a rapid beeping above all the other noises in a location, a vehicle is very close to you going backward, which means the driver may not be able to see you. Look around to check where it is and what it is doing.

Welding

The easiest method for anyone, including visitors, to injure themselves at a drilling location without actually doing anything is to be within sight of an arc welder. If you see a welder about to “strike an arc,” look away, as the high intensity of ultra-violet light can permanently damage the eye at surprising distances.

References:

- Alnabhani, Khalid. (2018). Safety During Offshore Drilling Operation. 10.1016/bs.mcps.2018.04.007.

- Oliveira, V. & Morooka, Celso & Mendes, José. (2004). A Study on Operational Safety in Offshore Drilling and Production Units. 2. 10.1115/OMAE2004-51375.

- academia – REQUIREMENTS_FOR_DRILLING_and WORKOVER_RIGS