This article is one of 22 articles explaining the casing design calculations in detail. Casing Burst Pressure Calculation is a significant aspect in casing design calculations as the burst loads on the casing must be evaluated to ensure the internal yield resistance of the pipe is not exceeded. The burst load is the force applied by the fluid inside the casing, which acts to rupture the pipe in the absence of external pressure. You can easily do your casing burst pressure table on an Excel sheet using the equation below.

These loads are generally caused by mud hydrostatic pressure inside the casing and perhaps some surface pressure. Fluids on the outside of the casing, called back-up fluids, supply a hydrostatic pressure that helps resist pipe bursts.

The resulting adequate burst pressure is the internal pipe pressure minus the external pressure. Burst conditions are established, and the least expensive pipe that will satisfy the burst pressure is tentatively selected.

The Importance of Casing Burst Pressure Calculation

It is important to perform an accurate casing burst pressure calculation for several reasons:

- Well Integrity: Overloading the casing beyond its burst pressure can lead to casing failure, which can compromise the integrity of the wellbore and result in production losses, costly repairs, or even environmental damage.

- One of the ways engineers ensure the safety of a wellbore and prevent potential accidents or blowouts is by calculating the maximum pressure that a casing can handle. This helps to make sure that the wellbore is operating within safe limits and that everyone involved in the drilling process can work with peace of mind, knowing that all necessary safety measures have been taken.

- As an engineer, you can optimize your casing design by calculating the correct burst pressure. By doing so, you can choose the right materials, pipe dimensions, and connection types that meet the specific requirements of your well. This will help you design a casing that is tailored to your needs and ensure that it performs optimally.

The API Casing Burst Pressure Calculation.

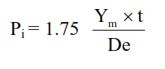

Casing Burst pressure calculation is given by a simple equation:

Where:

Ym: is the minimum yield strength of the pipe

t : is the wall thickness in inches.

De: is the outer diameter in inches.

Example:

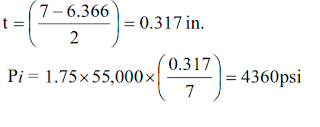

Calculate the burst rating for the 7” 23# J-55 casing.

Solution:

From Table 2, the Ym for the J-55 casing is 55,000 psi. The ID of 7” 23# casing in 6.377”, therefore,

References & Papers.

Burst Strength of Tubing and Casing Based on Twin Shear Unified Strength Theory

Abstract: Numerical and experimental comparisons show that the new burst strength model is much closer to the absolute burst values than other models. The research results provide an essential reference for optimizing deep and ultra-deep wells’ tubing and casing design.

Full information about casing calculation is needed