Use a casing roller when the casing is slightly collapsed. Casing rollers are light-duty tools. We recommend for you this article to read:

Tool Description

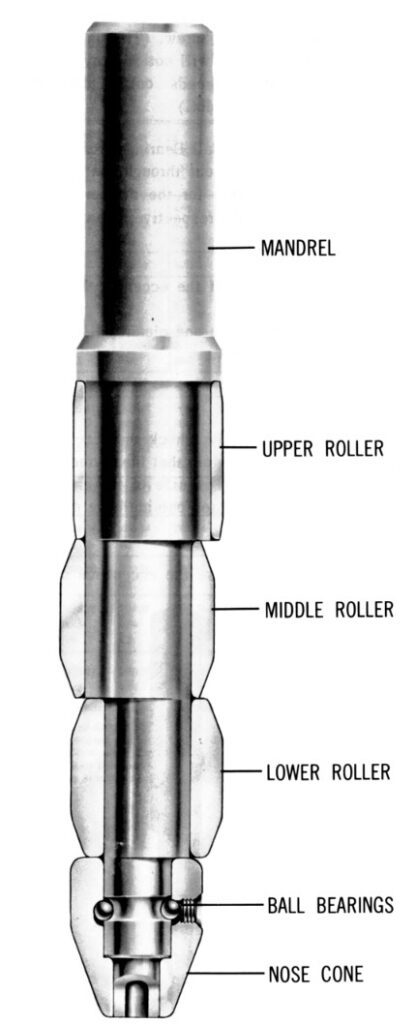

The CASING ROLLER is specifically designed for repairing casing and differs from any other repair tool intended for this application in that it does not include any small parts to be worn, broken, or lost in the well. We shall take the BOWEN Type as an example.

The Bowen Casing Roller rolls the casing out to its original ID dimension. The tool consists of a series of rollers and a tapered nosecone that are all mounted on an eccentric mandrel. As the tool rotates, one roller hits one side of the casing while another roller hits the opposite side of the casing, knocking the casing back into its original shape. The individual rolling elements are interchangeable.

Casing Roller Operating Guidelines

Make up the BOWEN TUBING and CASING ROLLER to either the drill collars or to the drill pipe; experience has shown that it is preferable to connect directly to the drill pipe. (Drill pipe Inspection should be recent)

The drill pipe and the roller are rotated at low speed and lowered slowly through the casing until the damaged area is tagged. Upon contact with the collapsed casing, increase the rotary speed to 40-75 RPM, start the mud pump and lower gradually.

The reduced portion of the tapered Nose Cone readily enters between the walls of the collapsed casing. As the Mandrel is rotated and lowered, the eccentrics force the Nose Cone and Rollers outwardly against the casing walls with great lateral pressure restoring the casing to its normal 1.0. and roundness.

Moderate to heavyweight should be used during operation. The use of too little weight, with high rotational speeds, is not recommended. Lightweight with high speeds tends to wear the rollers without performing a repair to the pipe. If insufficient weight is available in the running string, drill collars should be added. The best guide to the amount of weight and rotational speed is to use his experience; as long as steady downward progress is made by the Casing Roller, the weight-speed ratio is giving the proper results.

A severely collapsed casing will require more amount of weight for the Roller to enter into and straighten the casing pipes. The rugged construction of the BOWEN TUBING and CASING ROLLER allows the operator to apply the maximum amount of weight and torque without damage to the tool.

Maintain circulation throughout its operation.

| Step | Action |

| 1 | Rotate and lower the roller and the work string until you make contact with the damaged area. |

| 2 | Upon contact, increase the rotary speed to 50–75 RPM and lower the string slowly, with moderate weight. Note: A high rotary speed with insufficient weight will wear out the rollers without straightening the casing. |

| 3 | Make steady downward progress until the casing ID is restored. |