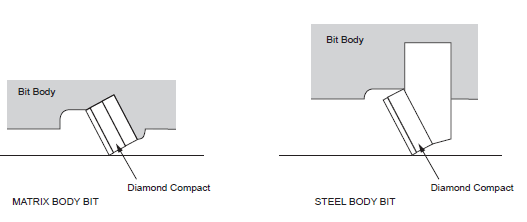

The PDC bit body may be

- Steel Body :

- The bit body is forged or milled from steel (steel-bodied bits).

- The cutters on a steel body bit are manufactured as studs.

- The stud can be set with a fixed back rake and/or side rake.

- Field experience with the steel body bit indicates that face erosion is a problem, but this has been overcome to some extent by applying a hard-facing compound.

- Steel body bits also tend to suffer from broken cutters due to limited impact resistance. This limited impact resistance is because there is no support to the stud cutter.

- They are preferred as they can be easily repaired but suffer from erosion.

- Matrix Body :

- Matrix Body Bits are constructed in a cast from tungsten carbide (matrix bit).

- They are more resistant to erosion but are prone to bit balling in soft clay formations due to their low blade height compared with steel-bodied bits.

- Matrix body bits have an economic disadvantage because the raw materials used in their manufacture are more expensive.