Drilling slips exert hoop compression on the Drill Pipe which can deform the pipe in unfavorable conditions. This article will teach the drill pipe slip crushing formula and calculations.

Slip Crushing Constant

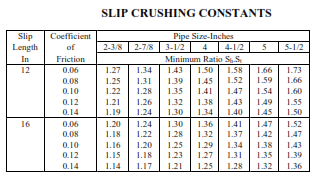

A unit tensile stress St from hanging weight will result in a hoop stress Sh that is a function of many factors such as slip length, coefficient of friction between slips and bowl, pipe diameter, and others. Based on that, a term was developed, the slip-crushing formula constant, which is defined for a given set of conditions as the ratio Sh/St. We have listed below various Slip-crushing calculation constants depending on many conditions.

Note: (If slip crushing occurs at less than predicted loads, the cause could be slicker than expected dope between slips and bowl).

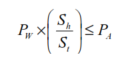

A coefficient of friction of 0.08 between slips and bowls is normally used. If the pipe is not stuck, the maximum tension carried by the slips is the working load, Pw, which is the buoyed weight of the Drill Pipe and Bottom Hole Assembly BHA. So that to prevent any deformation of the pipe, the working load Pw times the crushing constant should be less than 0.8Y or

- PW= Working load (lbf)

- Sh/St= Slip crushing constant

- PA= Allowable load (lbf)

Note: If the pipe is stuck and you desire to set the

slips with more tension than the working load, perform the calculation substituting the total tension on the pipe when the slips are set for Pw.

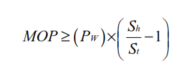

Slip Crushing and MOP

The constant may be considered when setting the margin of overpull (MOP) to ensure that the above equation is always satisfied. To do this, first determine MOP, then make sure that MOP satisfi es the following relationship:

If necessary, increase MOP to satisfy the equation.

Problem: Are the conditions in the above equation satisfactory from the standpoint of slip crushing? What minimum MOP would be satisfactory if the pipe was not stuck under these conditions? Slip length is 16 inches.

Solution: For 5-inch drill pipe:

- Sh/St = 1.42 (from Table 1.4)

- PW= 170,100 lbs

- PA= 270,100 lbs

(170,100 lbf) x (1.42) =241,542 lbf < 270,100 lbf

Therefore, the conditions are satisfactory. To calculate the minimum MOP to satisfy slip crushing:

MOP = 196,700 lbs x (1.42 – 1) = 82,614 lbf

The slip crushing analysis above assumes that slips, slip elements and bowl are in good condition. This should be confirmed regularly by both visual inspection and slip contact tests as outlined in the IADC Driller’s Manual.

Final Words

I suggest that you read more about this subject, especially in deep water. I have also found a good paper related to our subject: Advanced Considerations for Deepwater Drilling. Of course, if you cannot pay for it, you can use SCI-Hub services.