Introduction To Oil Well Casing Drill Bit Sizes Selection

The design of the casing Drill Bit sizes used in drilling oil / oilfield onshore and offshore wells using selection charts is performed from the bottom to the top, starting with the production tubing. But before proceeding in this article, you may be interested on our full guide for casing design & the drilling bit selection guide

The design mechanism of the tubing size is to maintain a specific wellhead flowing pressure or allow the well to produce at a specified flowrate. The size of the production Csg or casing liner (One of Types Of Casing) is based on the size of the tubing. The production Csg should have an inside diameter such that there is adequate radial clearance between the tubing and Csg to allow for fishing the tubing during workover operations.

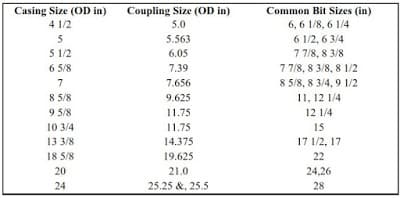

To correct place the production casing in the well, the necessary bit size to drill the last interval of the well must be 0.375”-0.5” or preferably 0.75” larger than the OD of the production Csg, see Table below.

Above table provides commonly drilling bit sizes that we use for drilling a hole which various API Csg strings generally can be placed safely without getting Csg stuck problems.

How to Select

The selected drilling bits sizes should provide sufficient clearance between the borehole of the drilled well and the casing to allow for drilling mud cake on the borehole and for installing casing centralizers and scratchers.

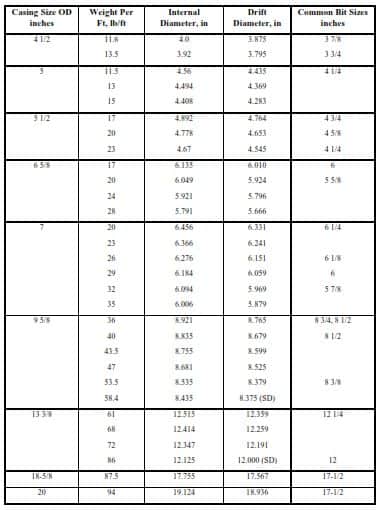

Sufficient clearance is also necessary to prevent premature dehydration of the cement and the formation of cement bridges during cementing Job. The bit used to drill the hole for the production casing must fit inside the casing string above, see below Table.

This, in turn, determines the minimum size of the second deepest casing string. With similar considerations, We are selecting the drilling bit size and casing size of successively shallower oil/gas well segments.

Above Table shows casing IDs and drift diameters for various standard casing sizes and wall thicknesses. The pipe manufacturers assures that a bit smaller than the drift diameter will pass through every joint of casing bought. In most instances, bits larger than the drift diameter but smaller than the ID will also pass, but this is not good drilling practice.

Conclusion

The most commonly used bit sizes are highlighted in above Tables. Selection of casing sizes that permit the use of commonly used bits is advantageous because the bit manufacturers make readily available a much larger variety of drilling bit types and features in these common sizes.

I didn’t know that.