Usually, Mud Engineers design drilling mud to be able to carry out mud basic functions. Thus, As the concentration of Cement contamination increases in a drilling mud system, there will be a detrimental effect on its performance. In general, we can define the contaminant as any material that causes undesirable changes in drilling fluid rheology and properties that will appear in mud lab tests.

Solids are by far the most prevalent contaminants. Excessive solids, whether commercial or from the formation, lead to high rheological properties and slow the drilling rate. While there are specific treatments for each contaminant, removing the contaminant from the system is not always possible. Pretreatment can be advantageous as long as it is not excessive and does not adversely affect mud properties. The instability in the drilling mud properties results from various contaminants in the mud system.

Generally, good drilling mud is simple and contains few additives. This allows easier maintenance and control of properties even at elevated temperatures and pressure. Planning each change in the mud of the time is important.

How Does Cement Affect Drilling Mud?

From a mud viewpoint, drilling cement introduces two primary contaminants. The primary contaminant is

- a calcium ion

- The second contaminant that compounds the problem is hydroxide ions.

Flocculating effects of increased calcium content, pH, and solids don’t significantly affect Invert muds. However, Cement will reduce base fluid-water ratios and, in turn, emulsion stability. Whenever possible, drill Cement with seawater or expendable water base mud before displacing it to invert mud. Off course, being stuck in cement is a big problem.

Water Based Mud, however, can experience severe complications if we are not considering precautions. Freshwater systems with high bentonite content or EZ-MUD systems are the most sensitive to cement contamination.

Generally, the rheological properties, filtration properties, and pH will dramatically increase as the calcium flocculates clay particles and polymers in combination with the high pH. EZ-MUD systems will liberate NH3 as the PHPA breaks down.

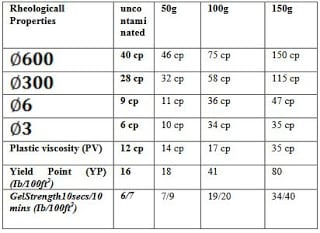

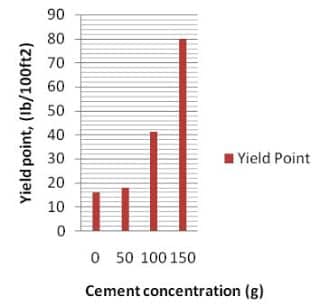

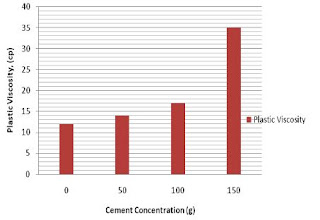

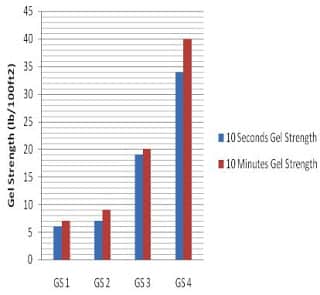

Experiment

There was an experiment on a tiny mud sample and 50g, 100g & 150g Cement. Then mud tests were done after adding such volumes of Cement. Below, you can see the effect of the contamination on water-based mud rheology.

Severely contaminated bentonite-based mud can solidify at high temperatures (greater than 250 F).

Drilling Cement Precautions

Proper planning and pretreatment will minimize problems associated with high flocculation, plugged flowlines, and cement-contaminated surface equipment. You can consider the following precautions if you plan to do a Cement job, mainly when there is a risk that the Cement is green.

- If possible, drill out as much of the Cement with seawater if a ready supply is available.

- Pretreat water-based muds with sodium bicarbonate 0.25-0.50 lb/bbl (0.70 – .50 kg/m3).

- Closely monitor mud returns at the shale shakers and immediately dump any green cement or badly contaminated Water Based Mud.

- If you plan to drill large cement sections and treatments are insufficient to counter the effects of Cement, convert to a lime-based system that tolerates high cement levels such as POLYNOX.

Normal Treatments For Contaminated Drilling Fluids

Under normal conditions, if you displace Cement with a spacer and treated mud, the quantity of Cement drilled will be manageable. A pretreatment with bicarbonate at 0.75 ppb (2.1 kg/m3) for 20” casing or 0.25-0.5 lb/bbl (0.70 – 1.50 kg/m3) for 13” or 9” casing will be sufficient. SAPP in very low concentration can also deflocculate the mud to reduce flocculation from Cement. Close monitoring of Mud returns is the key to adjusting further treatments with additional bicarbonate and water.

Conversion to a lime-based system

A type of water-base mud saturated with lime Ca(OH)2 and has excess lime solids (not dissolved) in reserve. Lime muds are classified according to excess lime content:

- low-lime, 0.5 to 2 LBM/bbl,

- medium-lime, 2 to 4 LBM/bbl

- High-lime, over 4 LBM/bbl.

All lime muds have a pH of 12, and the filtrate is saturated with lime. Fluid-loss additives include starch, HP-starch, carboxymethylcellulose (CMC), or polyanionic cellulose (PAC).

Prehydrated bentonite can improve the fluid loss and rheology of lime mud. Maltodextrin in lime muds has been used as a clay deflocculant and shale stabilizer to increase calcium solubility. KCl in lime muds has been another innovation for successfully drilling hydratable shales. One reason lime muds are used is the ability to carry very high mud alkalinity (as excess lime) to neutralize acid gases. H2S zones can be drilled more safely, and copious amounts of CO2 can be neutralized by a significant excess of lime.

How To convert to a lime based system

If it is necessary to convert to a lime-based system, the conversion can be carried out during drillCementment. The first step is to reduce the solids and MBT below 17.5 lb/bbl (50 kg/m3) with heavy dilution, followed by a treatment of 2 ppb (5.7 kg/m3) caustic soda and 3 ppb (8.55 kg/m3) CARBONOX. The increased pH of the filtrate will suppress calcium solubility and retard the solidification of the fluid. During the breakover to a lime system, it is possible to experience a “viscosity hump”. Lime and caustic additions must be made to continue going over the hump. If you allow pH to drop, the conditions will worsen, and the mud will remain viscous. A lime mud can be checked for a full breakover by adding more lime. The mud is broken if the fluid takes the lime without increasing viscosity.

Drilling Mud Contamination With Cement Summary

When drilling cement with or without WBM, it is critical to be fully aware of the potential problems. It is prudent to pretreat and prepare for the worst conditions than attempt to treat after the problem occurs. Nothing is certain when preparing for cement because of uncontrollable variables such as channelingCementment, varying hardnesses, and degrees of the interface. In many cases, economics will dictate the treatment. It may be more economical to discharge large quantities of contaminated mud Cementment than to treat and risk contaminating/recirculating Cement through the surface system. The key is preparation and planning for the worst case.

Yes best information

Good information thanks