In general, to cure lost circulation, you have to follow two major steps:

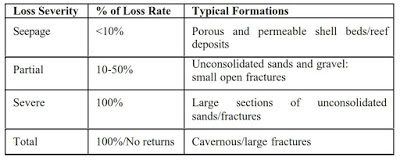

- First, Make an assessment of the severity of a loss zone. ( see table-1)

- Second, Match the remedial material and the below techniques to it in terms of both the size of the material and its function.

Prevention of mud loss is critical, but because lost circulation is such a common occurrence (check also: causes of mud losses), effective methods to cure lost circulation are also a high priority. Rock mechanics and hydraulic-fracture theory indicate that it is easier to prevent fracture propagation than it is to plug the fracture later to prevent fluid from re-entering.

It is good idea to load mud system with Lost circulation Material if you expect depleted zone or probable thief zone

Using an LCM that can be carried in the drilling fluid without significantly affecting its rheology or fluid-loss characteristics facilitates preventive pretreatment. Pretreatment can mitigate wellbore breathing (ballooning), seepage losses, and/or potential lost circulation when drilling depleted zones.

The best approach to control lost circulation is to make an assessment of the severity of a loss zone and match the remedial material and technique to it in terms of both the size of the material and its function.

Seepage Drilling Losses Remedial

Seeping losses can occur in any formation type when the bridging agents are not large enough to form a seal, or when there are no fine particles to complete the seal.

To cure seepage lost circulation, you have two techniques to be used

1- Pull Up & Wait

2- Mixing LCM / Squeeze Cement

Pull Up To Shoe & Wait Technique

In cases of seeping, partial or complete loss, the “Pullout to shoe and Wait” technique is common. The theory which supports this technique is that the fracture was created by putting excessive, unrequired pressure on the formation. If the pressure is removed the fractures will close and cure lost circulation during the waiting period. Now let’s move to the procedures:

- At the first indication of loss, circulation is stopped

- bit is pulled to the point of safety usually to the casing shoe.

Note : While tripping pipe care must be taken to minimize surge and swab pressures that could further break down the formation.

- The hole is then allowed to remain static for 4 to 8 hours.

- Speculating that returns will not be obtained by waiting I mix a pill of lost circulation material in the mud.

Mixing LCM Technique

If the hole will not stand full while waiting, the technique of mixing an LCM slurry containing fine to medium bridging agents or utilizing a high-filter-loss slurry squeeze should be considered.

This type of pill is generally made up of fine to medium grain LCM and rarely exceeds 43 kg/m3 (15 ppb) if it is to be pumped through jets of bit. Higher concentrations and coarser LCM can be used if open end string is placed next to the zone. If circulation is not regained after this pill, a squeezing or cementing technique should be considered.

Reducing mud weight if possible is another weapon to help curing lost circulation

Partial Circulation Losses Remedial

Partial circulation losses occur in gravel, small natural fractures and barely opened induced fractures . The same techniques used in seeping losses should be used in partial losses which are as following:

- The pull up and wait technique should be the first technique used to attempt to regain full returns.

- If the hole will not stand full while waiting, the technique of mixing an LCM slurry containing a blend of medium to large bridging agents or utilizing a high-filter loss slurry squeeze should be considered.

Again, Reducing mud weight if possible can help to cure lost circulation

Complete Circulation Losses Remedial

Complete losses occur to long, open sections of gravel, long intervals of small natural fractures, large natural fractures or open induced fractures

This is the procedures to attempt curing complete lost circulation:

- The pull up and wait technique should be the first technique used to attempt to regain full returns.

- Use high filter loss slurry squeeze technique.

How To Cure Complete Lost Circulation By High Filter Loss Slurry Technique?

Once the thief zone has been located, one of the following squeezing techniques may be tried to seal it off .All applications are similar, the main difference being in the size and type of LCM to be used. To attempt curing complete lost circulation using this technique, follow the following procedure:

- Locate the thief zone.

- Select LCM

- Place the pipe at or just above the thief zone, preferably open-ended.

- Close the pipe BOP rams and squeeze the slurry into the zone by pumping slowly.

Different types Of Squeezing Pills

- Bridging Materials in the mud either in water or oil base mud

- High filter loss slurry

- Downhole mixed soft plugs

- DOB plugs. (diesel oil + bentonite)

If returns are not regained with this technique, a hard plug such as a cement, cement-bentonite, cementgilsonite or diesel-oil-bentonitecement is recommended.

Don’t forget to reduce mud weight if possible.

Curing Partial Or Complete Circulation Loss To Deep, Induced Fractures.

- The pull-up-and-wait technique (4 to 8 hr) should be the first technique used to attempt to regain full returns.

- Apply soft plug squeeze technique .

- If the hole will not stand full while waiting, the technique of mixing an LCM slurry containing a blend of large bridging agents or utilizing a high-filter-loss slurry squeeze should be considered.

- Reduce mud weight if possible.

Curing Severe Complete Lost Circulation

Severe complete losses occur to large, open natural fractures, caverns and open induced fractures.

- Squeeze with either a high-filter loss slurry squeeze or large amounts of diesel-oil bentonite-cement slurries.

- If the severe, complete losses continue to occur as more open, natural fractures or caverns are penetrated, the technique of drilling blind or with aerated mud and setting casing should be considered.

- Reduce mud weight if possible.

The Secondary Losses Remedial Options

Sometimes LCM won’t be able to cure the mud losses, so there are other options as following

- Drilling Blind

- Pump Gunk Plug ( Please visit Gunk Plug article to understand its application and procedures)

- Pump Cement Plug

The Option Of Drilling Blind Solution

When losses cannot be cured, you have a choice to drill “blind” and to keep the hole filled with mud as best as possible. If the cuttings are large enough then they will act as bridging particles, or the void may eventually fill up, restoring mud returns at the surface.

The following procedures are recommended when drilling blind:

- Pump 50 bbl high viscosity sweeps for each stand drilled, to help push cuttings above the bit and BHA.

- Control ROPs to prevent a build up of cuttings in the annulus.

- Spot high viscosity, unflocculated Gel mud across any unconsolidated sand sections prior to tripping, as a precaution against possible caving.

- Fill the hole with high viscosity, unflocculated Gel mud prior to tripping out to run casing.

Using Cement Plug To Cure Losses

A cement plug may be spotted across the thief zone when all other attempts to cure formation losses have failed. This may be followed by a cement squeeze, which is achieved by closing the annular BOP and applying pressure to squeeze the cement slurry further into the thief zone. The cement plug is designed to seal off any fractures and voids, enabling drilling to resume after drilling through the cement plug.