In general, there are two main causes of lost circulation in drilling operations problems which are as follows:

- Invasion or mud loss to formations such as cavernous, vugular, fractured formations or unconsolidated formations.

- Fracturing which is mud loss due to hydraulic fracturing operations from excessive induced pressures.

As this article is one of five articles to cover the loss of circulation problems, I recommend visiting these links for a better understanding:

- Important Introduction For Lost Circulation Problem

- Remedial Of Lost circulation Problem,

- Precautions To be considered to avoid Mud loss problems

- Lost Of Circulation Material Used In drilling

Causes of lost of circulation In Drilling

A) Invasion

In many cases, lost circulation cannot be prevented in drilled formations that are cavernous, vugular, fractured or unconsolidated. Depleted low-pressure formations (usually sands) are similar relative to lost-circulation potential.

Coarse, unconsolidated formations

Coarse, unconsolidated formations can have sufficiently high permeability for whole mud to invade the formation matrix, causing lost circulation in drilling. This high permeability is often present in shallow sands and gravel beds. Formations that were once reefs and oyster beds also have similar tendencies. One important reason for preventing mud loss in shallow intervals is that it may cause these unconsolidated formations to wash out, forming a large cavity that is less stable which could cave in more easily from overburden and rig weight.

Depleted Formations

Another potential loss zone is in depleted formations (usually sands). Producing formations in the same field, or general vicinity, may cause subnormal (depleted) formation pressure due to the extraction of the formation fluids. In such a case, mud weights required to control other exposed formation pressures may be too high for the depleted formation, forcing mud to invade the low pressure depleted formation. If this situation exists, plans should be formulated to prevent such cause of lost circulation in drilling or stuck pipe from occurring in the depleted zone. Special bridging agents and sealing materials should be used to form a good seal and filter cake on the depleted zone.

Cavernous or vugular zones

Cavernous or vugular zones are usually associated with low-pressure carbonate (limestone and dolomite) or volcanic formations. In limestone, vugs are created by the previous continuous flow of water that dissolved part of the rock matrix (leaching), creating a void space often later filled with oil. When these vugular formations are drilled, the Drill String may fall freely through the void zone which will rapidly cause lost of circulation in drilling. The volume and persistence of this kind of loss depends on the degree to which the vugs are interconnected. Similar vugs and caverns can develop during the cooling of volcanic magma or ash. Cavernous and vugular formations are often easily traceable from offset wells and predictable from mud logs and lithology.

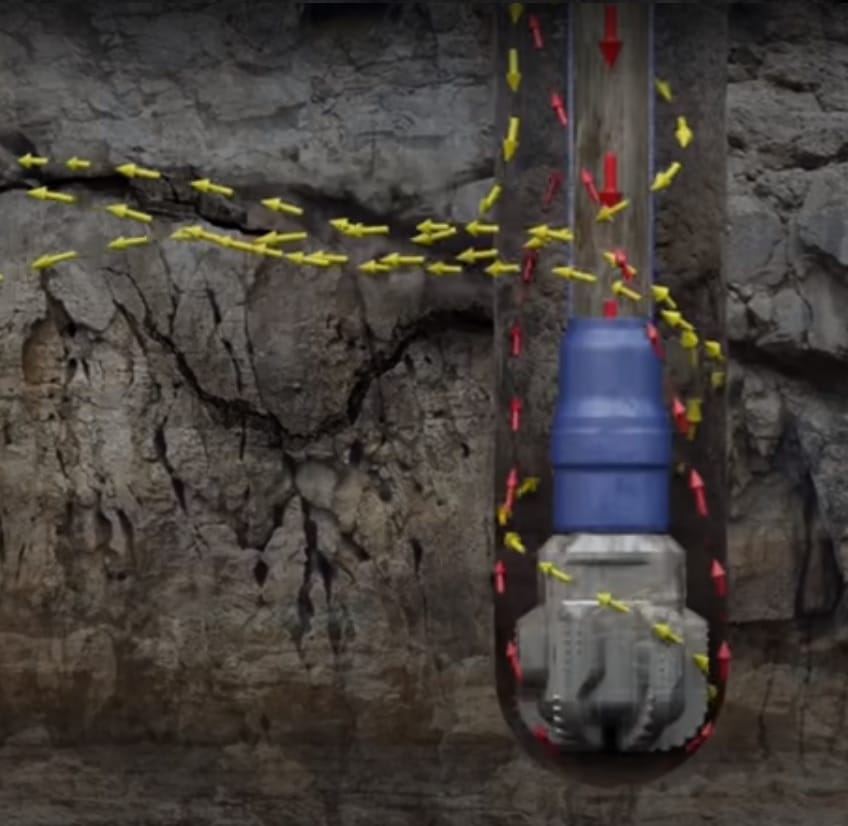

Fissures Or Fractures

Mud loss also occurs to fissures or fractures in wells where no coarsely permeable or cavernous formations exist. These fissures or fractures may occur naturally, or may be initiated or extended by hydraulically imposed pressures. Natural fractures exist in many cases, which may be impermeable under balanced pressure conditions. Losses may also occur at unsealed fault boundaries.

B) Fracturing

Hydraulic Fracturing

Hydraulic fracturing is initiated and may cause a lost of circulation occurs when some critical fracture pressure is reached or exceeded. Once a fracture is created or opened by an imposed pressure, it may be difficult to repair (heal) and it may never regain the original formation strength, as shown later in Figure 5. Lost circulation may persist even though the pressure is later reduced. This is the cause why it is better to pretreat for, and prevent, lost circulation in drilling than to permit it to occur. Lost circulation resulting from induced pressure is usually caused by one of two situations: Setting intermediate casing in the wrong place. If casing is set above the transition zone crossing from normal to abnormal pressures, the pressures exerted by the heavier mud (required to balance the increasing pressures) will often induce fracturing at the weak casing seat. Losses due to fracturing are most commonly near the previous casing seat, not at bit depth, even if casing is properly set.

Excessive downhole pressures.

These pressures are the result of many conditions including:

1) Mechanical forces.

- Improper hydraulics. Excessive pump rates and velocities causing high Equivalent Circulating Density (ECD) pressures which may cause a lost of circulation problem especially while drilling operations.

- Increasing pump rates too rapidly after connections and trips. This can be extremely important when dealing with drilling oil-base fluids. Failure to bring the pumps up to speed slowly can put much higher circulating pressures on the formation due to the tendency of drilling oilbase muds to thin at higher temperatures generated while circulating and to thicken at lower temperatures during trips. It is common for circulating pressures to decrease 100+ psi as the mud heats to circulating temperature.

- Raising or lowering the pipe too fast (surge/swab).

- Spudding bridges.

- Excessive Penetration Rate (ROP) for a given flow rate will result in high cuttings concentration in the annular fluid causing a high ECD.

- Pipe whipping.

2) Bad Hole conditions.

- Sloughing shale or increased solids loading in the annulus and high equivalent circulating density.

- Accumulation of drilled cuttings in a washed-out portion of the hole or in the drilling mud.

- Cuttings beds or Barite sag forming on the low side of a directional well, or possible slumping.

- Bridges.

- Kick and well-control procedures.

3) Mud properties.

- Excessive viscosities and gel strengths.

- Buildup of drilled solids.

- Thick filter cakes that reduce the hydraulic diameter of the wellbore.

- Excessive mud density or increasing mud density too fast.

- Unbalanced drilling mud columns.

- Barite sag.