Bow-spring casing centralizers are also available in multiple styles, including flexible and rigid, welded and nonweld, single piece, and other.

Conventional Bow-Spring Centralizers

Conventional bow-spring centralizers are the most common type of centralizers (Fig. 1). Also referred to as imperial bow, this centralizer type offers curved flexible bows that can expand or compress according to the variations in casing and hole diameter encountered while casing running in hole.

Typically, the centralizer’s uncompressed bow diameter is larger than the open hole (overgage). As the centralizer enters the casing, the bows compress, and the collars move apart, increasing the centralizer’s overall length.

Performance

The American Petroleum Institute (API) describes the performance of a bow-spring centralizer in terms of its starting force, running force, and restoring force.

- The running force is the average force required to move the centralizer through a specified wellbore diameter.

- The starting force is the maximum force required to insert the centralizer into a specified wellbore diameter.

- Restoring force is the force exerted by a bow-spring centralizer against the casing to keep it away from the wellbore wall. In essence, restoring force represents the ability of the centralizers to keep the casing “centralized” and has a direct impact on the corresponding amount of annular clearance available to fill with cement.

- Starting and running forces directly impact the casing drag while running in hole and when reciprocating the casing.

API Specification 10D defined a procedure to test, measure, and report the centralizer’s starting, running, and restoring forces. Understanding the testing procedure is most beneficial when evaluating centralizer options for difficult applications.

Applications

We normally use conventional bow-spring in vertical or low-inclination holes For the following reasons:

- Over-gauge conventional bow-spring centralizers generally allow for better centralization in washouts or enlarged hole sections.

- In addition, the restoring force of most bow designs increases with compression. However, running forces may be significant and hinder casing running.

In highly inclined wells, we may install conventional bow-spring centralizers in the vertical- or low-inclination sections and solid body centralizers in the lateral.

Types

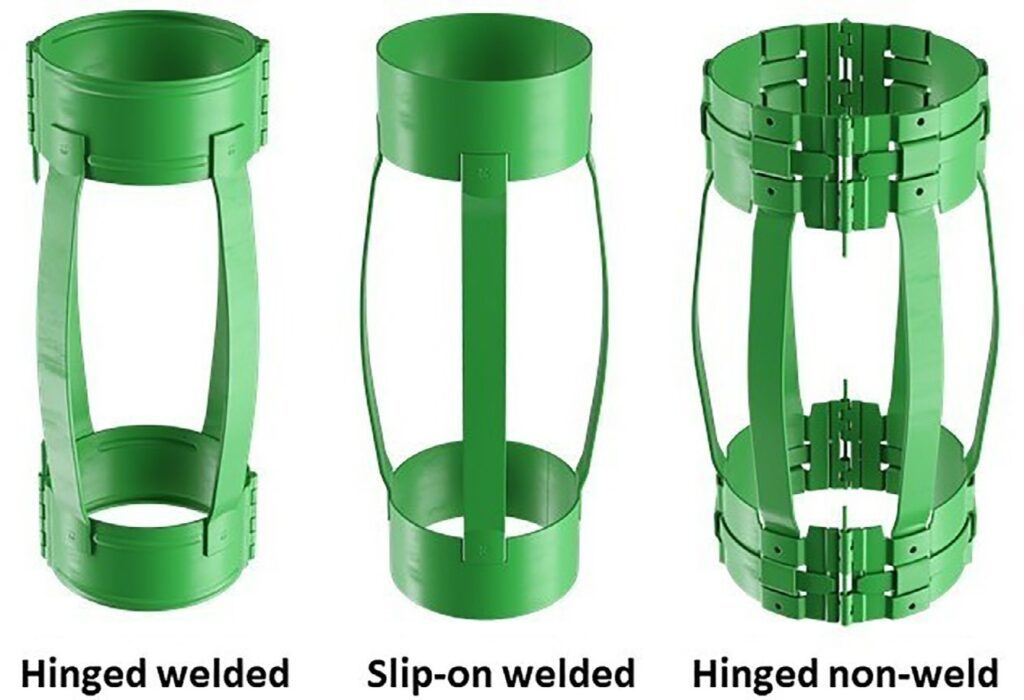

Conventional bow-spring centralizers are available in welded and non-weld designs.

- Welded bows are the most common type and tend to have higher starting, running, and restoring forces.

- Nonweld construction eliminates the risk of weld breakage, but the centralizers are generally more flexible once assembled.

Installation

From an installation perspective, conventional bow-spring centralizers are offered in hinged or slip-on designs.

- Hinged designs are more commonly used, as they allow centralizers to be laced onto the casing over couplings or stop collars, Fig. 2 that will reduce the risk of breakage. However, the centralizer hinge may not pass the restrictions that slip-on design does. Also, it requires special nails that usually take extra time.

- Slip-on designs eliminate these limitations, making the installation easier. Without hinges, slip-on bow-spring centralizers can also pass through smaller annular restrictions. Installation is limited to between stop collars or couplings, requiring the centralizer to be pushed into the hole.

- Some bow-spring designs also offer set screws that allow the centralizers to be fixed to the casing, eliminating the need for stop collars. Note: This type may restrict casing rotation.

- Bow-spring centralizers are also fitted with fins to promote fluid agitation and distribution during well conditioning and cementing in drilling. These fins may impede installation over the coupling and should be considered when defining how the centralizers will be installed in the field.

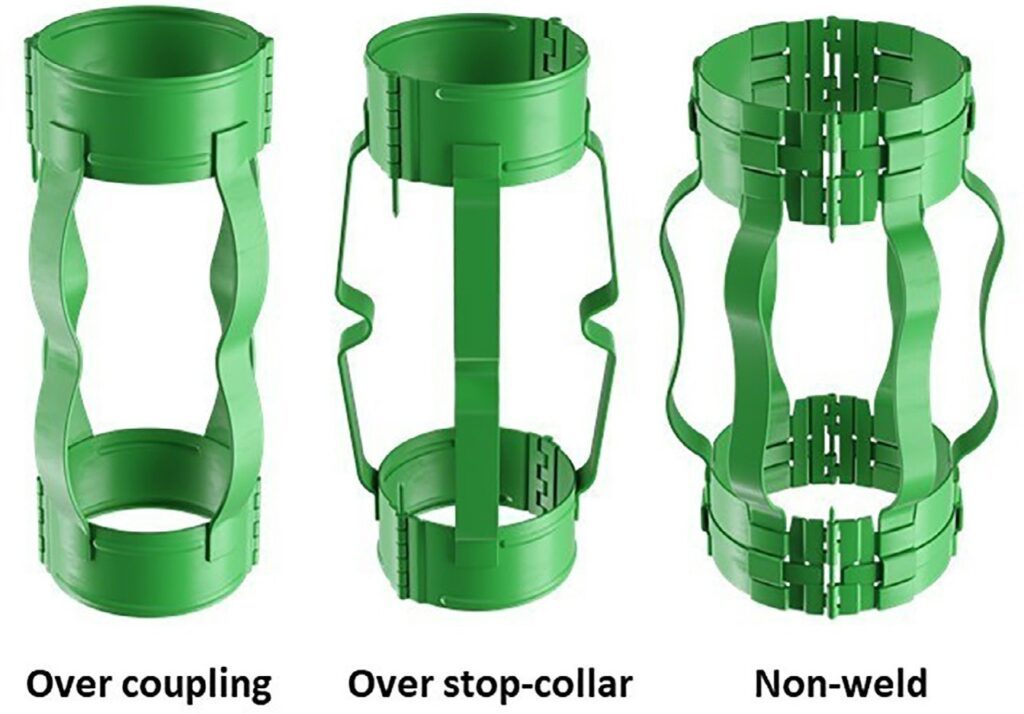

Semipositive bow-spring centralizers

Fig. 3 shows common types of semi-positive bow-spring centralizers. This design is also known as semirigid, double-bow, or tandem-rise. They are available in welded or nonwelded designs.

These centralizers offer stronger bows with higher restoring forces for improved casing centralization. To reduce the drag forces, semi-positive bow-spring centralizers are most commonly run at gauge, with the uncompressed bow diameter equaling the hole size. Therefore, the starting and running forces are significantly lower than those of conventional bow-spring centralizers. However, this may limit centralization in washouts or enlarged hole sections.

The reduced inside diameter (ID) at the centralizer center part may limit installation over the couplings or certain stop collar types. If overlooked, this important consideration may impact field operations, NPT, or even failure.

Rigid Bow Centralizers

The major component of a rigid bow is the rigid bars. Unlike conventional bow springs, the bars are not flexible and are typically only recommended for cased-hole applications. The centralizers are commonly available in hinged or slip-on designs, as shown in Fig. 4.

One-piece Bow Spring Centralizers

The one-piece bow-spring centralizer is the most recently introduced design, as shown in Fig. 5. This centralizer is typically constructed from a single sheet of metal cut, rolled, formed, and welded at the collars. Therefore, this design offers increased robustness and performance and reduced minimum compressed OD.

Due to the centralizer’s construction, the bows have a curved profile, resulting in higher restoring forces than conventional bow springs. Typically, the uncompressed OD is equal to or slightly lesser than the open hole, significantly reducing the starting and running forces. As a slip-on design, most one-piece centralizers are installed between stop collars or free-floating between the casing joints resulting in less risk of damage. Some designs allow for a stop collar to be placed inside the centralizer.

The one-piece design is a common alternative to solid body centralizers in highly deviated and extended reach wells. A larger flow-by area and some bow flexibility may allow for a more aggressive centralization program to improve the drilling mud removal and cement placement.

The increased robustness also makes it a better option than conventional bow-spring designs for close tolerance applications (i.e., deepwater, under-reamed wells) or when rotating while cementing.

Spiral bow-spring centralizers

A less common but available design, bow-spring centralizers with spiral bows offer advantages under specific well conditions. In highly deviated wells, where a key seat or axial groove has formed in the lower part of the well, spiral bows may help bridge the keyseat to minimize the loss of stand-off (eccentricity). Under some conditions, a spiral design may also help the removal of excess mud cake and promote fluid agitation. However, this widely unavailable design is more difficult to manufacture and install.