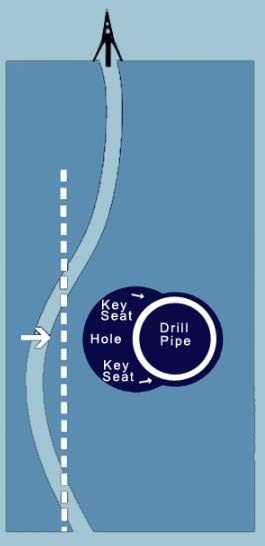

We can define Key seating term in drilling as a groove in the hole side made by the Drill Pipe rotating against the borehole wall at the same point and wearing a groove or key seat in the wall. During tripping pipe out of the hole, the Bottom Hole Assembly BHA, Drill Collar, Stabilizer, Mud Motor, or any big diameter component may wedge into one of these large grooves, which may be too small for it to pass through. This Key Seating sticking will likely happen in a soft formation in directional wells while dropping the inclination. It can also occur at the casing shoe if a groove is worn in the casing pipe.

Where the drilling problem Key seating happens:

- At abrupt changes in angle or direction in medium-soft to medium-hard formation. This abrupt change will make the drill pipes always make a channel in the same position as drilling continues.

- Where high-side wall forces and Drill String rotation exist.

- While pulling out of the hole.

- After long drilling hours with no wiper trips through the dogleg section. Wiper trips will help smooth such key seating and help RIH and POOH through it with a lower probability of a Stuck Pipe problem.

Mitigation Measures

The Preventive measures depend on keeping any turns or ant angle changes in the wellbore gradual and smooth and enlarging the grooves created by the Drill Pipe so that the more extensive diameter tools such as Drill Collar, Heavy Weight Drill Pipe HWDP, Bottom Hole Assembly BHA, and the casing strings will pass through it.

- The first thing to think about is the Wiper Trips.

- Directional Driller (Check also Driller Job Descriptions) had to build angles and turn smoothly to decrease dogleg severity.

- In the well planning phase, if you suspect a key seating problem, you have to plan for using String Reamers and wipers in Bottom Hole Assembly BHA.

What is the Key Seating Wipers

The Key Seating Wiper is installed just above the top Drill Collar. It contains a sliding Reamer sleeve with an O.D. slightly larger than the Drill Collar. When POOH, its sliding Reamer sleeve meets the key seat first – instead of the Drill Collar – by becoming wedged in restricted space.

By releasing the Drill Pipe, the sleeve may be jarred out of the key seat. A clutch drive on the bottom of the sleeve and the lower body is engaged by right-hand rotation.

Slowly raising the Drill String and continuing rotation allows the sleeve to function as a Reamer and wipe out the key seat. The operation may be repeated to further enlarge the area, thus permitting free passage of the Drill Collar.

Recognization & Indicators

It is so simple to detect such a problem. From its definition, we already know that you can expect it during POOH with the Drill String in soft formations, abrupt change in Inclinations, and azimuth. Below are the main indications that you would like to know.

- It occurs only during POOH.

- Sudden overpull as Bottom Hole Assembly BHA reaches dogleg depth.

- Free Drill String movement below key seating depth is possible if not already Stuck.

- Cyclic erratic overpull at Tool Joint intervals on trips as each Tool Joint keeps meeting the key seating.

- Large dogleg.

- Highly deviated wells.

- Circulation is possible.