Surface Mud Logging Basics & Theory

Mud Logging was introduced as a commercial service in 1939. The service provides for continuous on-site inspection, detection, and evaluation of the rock units as they are being drilled with regards to correlation and potential hydrocarbon production. Correct methods of obtaining this data and its subsequent evaluation are very important factors in all exploratory programs. Its effectiveness depends primarily upon the mud logging geologist.

The crushed “cylinder” of formation, which is drilled to make the borehole, is released into the mud stream. Once released, the formation and any contained fluids, are carried to the surface by the drilling fluid. Surface mud logging largely becomes a matter of extracting this information in terms of restoring (recording on the Formation Evaluation Log) the original in-place characteristics of the formation.

The first disturbance of the subsurface strata, as a result of being drilled, is that of varying amounts of flushing, which is caused by the mud filtrate. Ordinarily, the drilling fluid exerts a hydrostatic pressure on the formation in excess of the formation pressure. This causes the formation to act as a filter medium upon which wall cake is deposited and through which any water filtrate permeates, flushing interstitial fluids away from the wellbore.

On the bottom of the hole, where new formation is being continuously exposed and wall cake is not permitted to accumulate, the filtration rate is always at a maximum.

Factors that affect the amount of hydrocarbons remaining in the formation after flushing and which, in turn, affect the amount of oil and gas entrained in the drilling fluid are:

- Depth.

- Rate of Penetration.

- Size of the borehole.

- Volume of drilling fluid circulated.

- Physical properties of the formation.

- Properties of the drilling fluid.

During the surface evaluation, it is reasonable to assume that most formations have been flushed to the extent of being completely depleted of producible hydrocarbons before being drilled (though more often flushing will be to a lesser degree).

After undergoing flushing, the formation is subjected to the bit action, then released into the mud stream in the form of rock chips or cuttings. These are subjected to the circulating pressure of the mud column. During their travel from the bottom of the hole to the surface, the cuttings undergo a normal production cycle, that is, the pressure and temperature they were subjected to at depth is reduced to atmospheric conditions.

Gases (if present) and liquids (to a lesser degree) expand due to this pressure and temperature reduction, causing the cuttings to release into the drilling fluid any fluids which they contained, permeability permitting. Thus, upon reaching the surface, the cuttings may have been depleted of hydrocarbons, either by flushing or production. For this reason, a great deal of importance is placed on the hydrocarbon content of the drilling fluid as a source of information for evaluating the formation being drilled.

The fluids released from the cuttings and conveyed to the surface by the mud are the basis for several measurements by surface mud logging instruments and methods. These readings are important considerations in the continuous evaluation of the productive possibilities of the wellbore as it is being drilled. This is not to discount the importance of cuttings in formation evaluation. The cuttings are samples of the potential reservoir rock. Aside from their importance as a basis for correlation and stratigraphic purposes, they afford the means of “first study” of the reservoir characteristics of the formation. However, they must be studied and evaluated, bearing in mind that they may have been extensively flushed and produced.

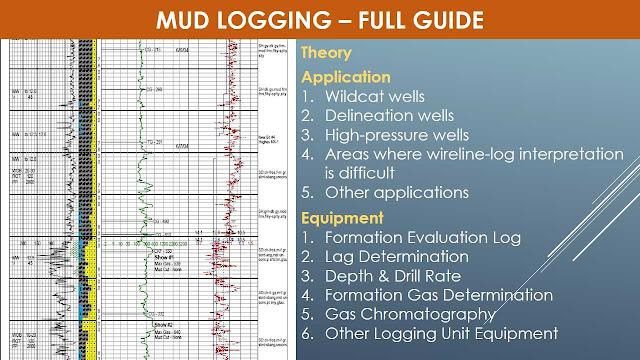

Surface Mud Logging Applications

Surface Mud Logging is standard on exploratory and field development wells where specific applications are involved, such as:

Wildcat wells

Mud Logging is used in wildcat wells specifically in areas where detailed subsurface information is lacking.

Delineation wells

Delineation wells is another application of surface mud logging sedimentary and structural changes make subsurface correlation difficult.

High-pressure wells

In high pressure wells surface mud logging is used to supply complete downhole information, a warning of pending problems are possible, thus aiding in the controlling of high-pressure zones.

Areas where wireline-log interpretation is difficult

information is provided on wells where wireline logs are not run (horizontal or sidetracked wells) (check also: sidetracking well) or where the drilling fluid prevents accurate interpretation.

Surface Mud Logging is used as a correlative tool to enable operators to change or modify their well programs so that possible productive formations are not missed and can be further evaluated by one of the following:

Conventional coring

Drill breaks can be evaluated by the mud logging geologist and the need for coring can be determined or drilling resumed with a minimum loss of time. Coring of nonproductive formations is reduced to a minimum.

Wireline logging

In expensive wildcat wells, suites of wireline logs may be run if the FEL depicts shows prior to TD (total depth).

Sidewall coring

In some areas, wells may be drilled to TD without taking conventional cores. After a wireline log run, the FEL can be used for correlating zones of interest for sidewall samples.

Drillstem tests

It is desirable in many areas to test possible productive formations as the well is being drilled, therefore drilling may be halted when shows occur. Testing is restricted to those zones showing some promise of production.

Using surface mud logging to its greatest advantage depends on several factors. One is the client’s knowledge of the subsurface. Another is the consideration given to downhole mechanical factors. Others include the reliability of correlation with other wells and the oil company’s philosophy towards the well in question.

Surface Mud Logging Equipment

To fully understand the various application of mud logging while drilling, the drilling engineers shall understand the parameters that can mud logging unit provide while drilling operations which are as follows:

- Formation Evaluation Log

- Lag Determination

- Depth & Drill Rate

- Formation Gas Determination

- Gas Chromatography

- Other Logging Unit Equipment

In Mud Logging Unit Equipment Article, we shall discuss all the above items in more detail.

5 Most Read Technical Papers Related To Mud Logging

If you are a student and don’t have the ability to access these papers, you can use SCI-Hub services.

- Advanced Mud Logging (AML) aids formation evaluation and drilling, and yields precise hydrocarbon fluid composition

- Recent advances in well logging and formation evaluation

- Mud Analysis Logging

- Mud Analysis Logging And Its Use In Formation Evaluation

- Comparative study between well logging and core analysis of Hawaz reservoir in Murzuq Basin, Libya