In this article, we shall discuss Drill Pipe Capacity Calculations (Fill-Up, Displacement Volumes in both open-end & bull plugged). At the end of the article, you can also download a sample excel sheet for Drill pipe capacity calculations

How To Perform Drill Pipe Capacity Calculations

Capacity may be a term frequently used interchangeably with volume. As utilized in the oilfield, it’s the quantity that a particular length of pipe will hold. Knowing the form of the pipe is round; the quantity is often calculated by hand.

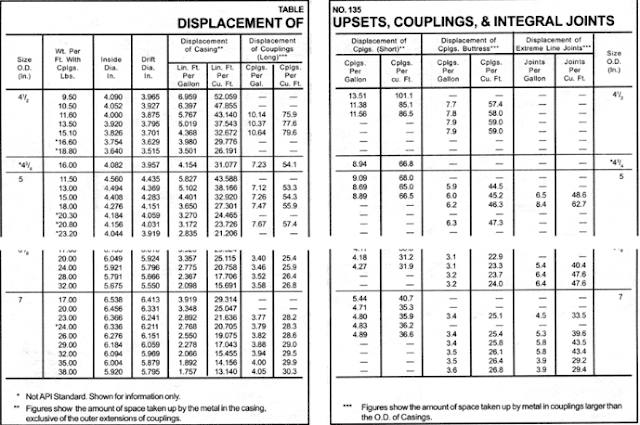

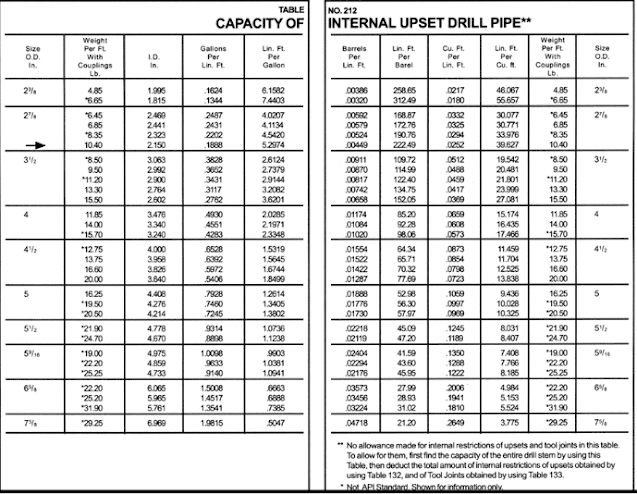

In this part, we will discuss fill-up and displacement calculations. Capacity calculations are one among the various sorts of mathematical problems which will be greatly simplified by using the Halliburton Cementing Tables (Red Book). Section 210 (Capacity) lists capacity factors for various sizes of drill pipe, tubing, casing, and open hole. Currently, these are listed in terms of gallons per foot, barrels per foot, and cubic feet per foot (Fig.1).

To use the Capacity tables, locate the correct table for the type of pipe you’re dealing with: drill pipe, tubing, casing, or open hole. Next, locate the dimensions and weight of pipe within the two left columns.

(Note: For tubing, there are four columns.) Then find the volume units you want across the top. Read the capacity factor where the columns intersect.

Sample Problem

What is the capacity, in gallons, of 1000 ft of 2-7/8 in., 10.4 lb/ft internal upset drill pipe? Use the sample of Section 210 shown in Figure 5.1 to assist your calculations.

Solution

Find the appropriate capacity factor (in gal/ft) in Figure 1 & multiply it by the drill pipe length.

Capacity Factor = 0.1888 gal/ft

Capacity = 0.1888 gal/ft × 1000 ft = 188.8 gal

A) Fill-Up Drill Pipe Capacity Calculations

Fill-up of pipe is defined because the length of pipe a specified volume will fill. Fill-up factors also are listed in Section 210 of the Red Book.

Sample Problem:

What is the length in feet of 3.5 in., 15.50 lb/ft internal upset drill pipe will 25 barrels of oil fill? Use Figure 1 to help in your calculations.

Solution:

Fill-up Factor = 152.05 ft/bbl

Fill-up = 152.05 ft/bbl × 25 bbl = 3801.25 ft

B) Pipe Displacement Calculations

In the oilfield, the terms displacement and displace may make confusion. The term displace often refers to pumping the fluid inside any pipe out of the pipe, as in displacing Hi-Vis Pill with water ( check also Mud displacement procedures). To do this, the quantity of fluid pumped is typically equal to the capacity of the pipe.

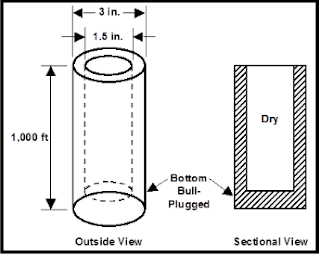

Bull-Plugged Closed End Drill Pipe Displacement

Figure 2 illustrates the volume of fluid displaced when the bull-plugged pipe or closed-end drill pipe is run in the hole. This volume is equal to the outside diameter’s flat surface area multiplied by the length of the pipe:

Displacement = OD Area × Length

or

Displacement = 0.7854 × OD × OD × Length

Sample Problem

Calculate the displacement, in barrels, for the bull-plugged pipe shown in Figure 2?

Solution:

- Convert 3 inches to feet | 3/12 inches/ft = 0.25 ft

- Displacement = 0.7854 × 0.25 ft × 0.25 ft × 1000 ft = 49.09 ft^3

- Conversion factor = (located in (Red Book) section 240, page 85) = 0.1781 bbl/ft

- Displacement = 49.09 ft 3 3 × 0.1781 bbl/ft = 8.74 bbl

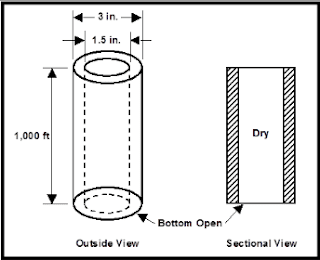

Open-Ended Drill Pipe Displacement

When the drill pipe is open-ended (that is, some opening permits the pipe to fill up on the inside as it is run into the hole), it’ll displace less fluid than the bull-plugged pipe. In Figure 3, you can see open-ended drill pipe will displace a volume equal only to the volume of steel placed in fluid. This displacement is often estimated by multiplying the cross-sectional area by the length:

Displacement = Cross-sectional Area × Length

Sample Problem

Calculate the displacement, in barrels, for the open-ended pipe shown in Figure 3?

Solution:

OD = 3 in. = 0.25 ft, ID = 1.5 in. = 0.125 ft

OD Area = 0.7854 × 0.25 ft × 0.25 ft = 0.0491 ft^2

ID Area = 0.7854 × 0.125 ft × 0.125 ft = 0.0123 ft^2

Cross-sectional Area = 0.0491 ft^2 – 0.0123 ft^2 = 0.0368 ft ^2

Displacement = 0.0368 ft^2 × 1000 ft = 36.8 ft

Conversion Factor = 0.1781 bbl/ft^3

Displacement = 36.8 ft^3 × 0.1781 bbl/ft^3 = 6.55 bbl

NOTE: In the above examples, it has been assumed that the tubular goods were flush joint; that is, no allowance was considered for internal upsets, external upsets, or couplings. Section 130 of the Red Book includes factors that allow for upsets and couplings, as illustrated in Figure 4.