In this article, we will talk mainly about the application for different types of bottom hole assembly (slick BHA drilling, Pendulum Assembly, & Packed BHA), its design & components. This article is a part of our drill string design guide.

In general, there are three types of Bottom Hole Assembly BHA In drilling:

- Slick BHA Type

- Pendulum BHA Type

- Packed BHA Type

The Slick BHA

This type of bottom hole assembly (slick BHA) consists of a Drill Bit and Drill Collar without a Stabilizer. Slick BHA is suitable for formations that have mildly crooked hole tendencies. Slick Bottom Hole Assemblies are seldom used. As there are no expensive components in this type of BHA, It is easier to fish such BHA.

Sometimes, we want to wash and ream (clean out) in some difficult holes. We choose to pull out of the current directional BHA. Then, we try to design a slick BHA but with the same configuration as the directional BHA. In other words, it will be a slick BHA, as you won’t add any BHA component. Still, you must use stabilizers with the same OD and position as in the previously used directional BHA. That is to keep the geometry of the cleaning assembly (which will be slick BHA with some stabilizers the same as the geometry of the directional bottom hole assembly).

The Pendulum BHA Assembly

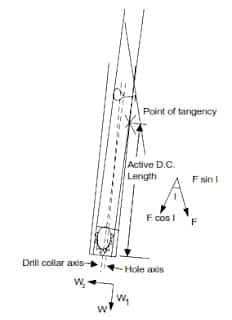

The Pendulum Bottom Hole Assembly (BHA) is a type of BHA that is used to reduce or maintain hole deviation during drilling. This technique uses the force of gravity to deflect the hole vertically. The force of gravity, known as F sin I in the figure, is affected by the length of Drill Collars between the Drilling Bit and the point of tangency. The force in the along-hole direction is F cos I, which aims to maintain the current hole direction.

The Pendulum BHA Assembly & Design

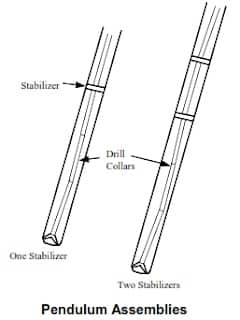

The pendulum type of bottom hole assembly BHA consists of a Drilling Bit, several Drill Collars to provide the pendulum force and one or more Stabilizers. Lubinski presented charts for determining the location of the first Stabilizer from the Drilling Bit and the weight that can be applied on the Drilling Bit to maintain the best position of the Stabilizer is as high as possible, provided the Drill Collars below the Stabilizer do not contact or barely contact the wall of the hole.

The optimum position of the Stabilizer depends upon the size of the Drill Collars, the hole size, hole inclination, and Weight On Bit (WOB). So if we can maintain the weight On Bit (WOB) from the graphs constant, the hole deviation will not change. If the Weight On the Bit (WOB) increases, the hole angle will increase, and the opposite is true.

The Pendulum BHA Assembly Disadvantages

- When using the pendulum Bottom Hole Assembly BHA, placing the Stabilizer within a few feet of a specific position obtained from the charts is essential.

- Also, if we need to change the weight on bit, we will have to pull the BHA to change the position of the Stabilizer.

The Packed Bottom Hole Assembly

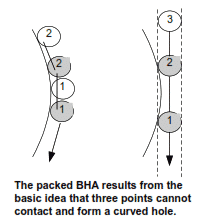

It relies on the principle that two points will contact and follow a sharp curve, while three points will follow a straight line, as shown. We can obtain three-point stabilization by placing three or more Stabilizers in the portion of the hole immediately above the bit.

Packed Bottom Hole Assembly BHA Types:

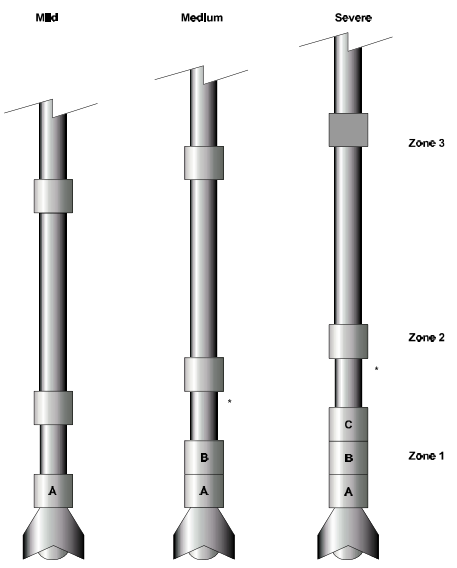

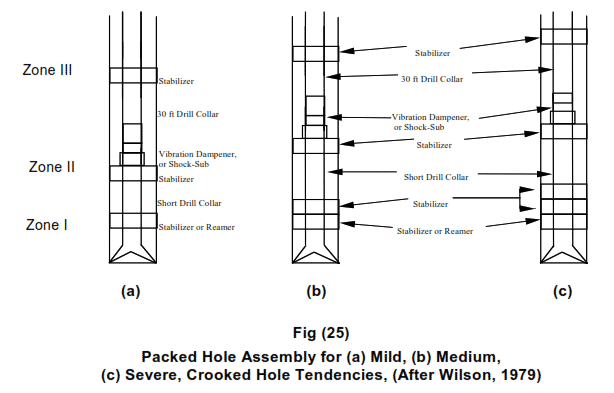

In the Figure below, you can see three basic assemblies that are required to provide the necessary stiffness and stabilization for a packed hole assembly. To reduce the amount of deflection caused by the drill collar weight, a short drill collar is used between Zone 1 and Zone 2. As a general rule, the length of the short drill collar in feet is approximately equal to the hole size in inches, plus or minus two feet. For example, if the hole size is 8 inches, a short drill collar length of 6 to 10 feet (23 meters) would be satisfactory.

Mild Crooked Hole Packed BHA

We are using this bottom hole assembly type for formations that have mildly crooked hole tendencies that produce little or no deviation, such as hard and isotropic rocks. The three-point stabilization is provided at Zone 1, immediately above the Drilling Bit; at Zone 2, immediately above a short, large OD Drill Collar; and at Zone 3, on top of a standard-length Drill Collar.

Note: If a vibration dampener (shock absorber) is necessary, we should place it in Zone 2 for maximum effectiveness.

Medium Crooked Hole Packed Bottom Hole Assembly BHA.

We always utilize this type of Bottom Hole Assembly BHA for formations with medium crooked hole tendencies, such as medium and soft formations. In this type of Bottom Hole Assembly BHA, we place a second Stabilizer at Zone-1 to provide increased Drilling Bit stabilization against deviation effects of the formation.

Severe Crooked Hole Packed BHA

Drilling engineers utilize this type of Bottom Hole Assembly BHA in drilling formations with severely crooked hole tendencies, such as medium and soft formations, which show a great degree of dipping, fracturing, and variation in strength. Remember that in this type of Bottom Hole Assembly (BHA), we need to include three stabilizers in Zone 1.

Forces Acting On Types of Bottom Hole Assembly

The tendency of bottom hole assembly (Drilling BHA) is affected by the Forces Acting On Bottom Hole Assembly, which will drive it in a certain direction. These Forces must be understood to choose the most applicable Bottom Hole assembly BHA type. Let’s return to our main subject, Step By Step Learn How To Perform Full Drill String Design.