Drilling string stabilizer types & design is the main subject of this article. First, we will introduce to you the definition of a stabilizer. Then, we will move to the stabilizer application. Finally, we will talk about its types. This article is a part of the series explaining Bottom Hole Assembly Components, Types & Mechanism.

Drilling Stabilizer Definition

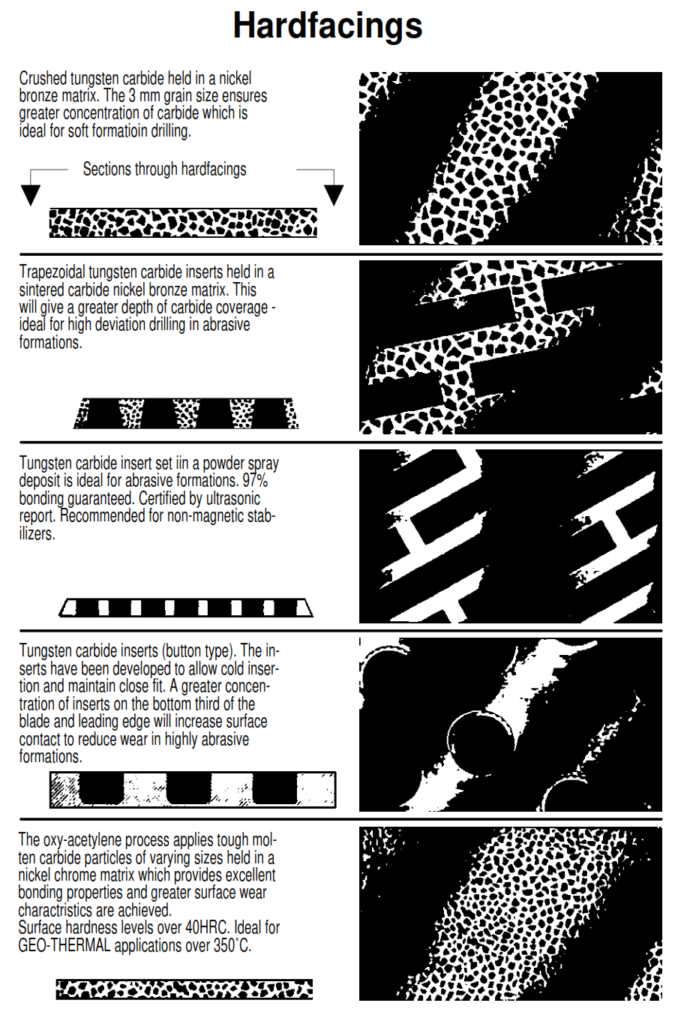

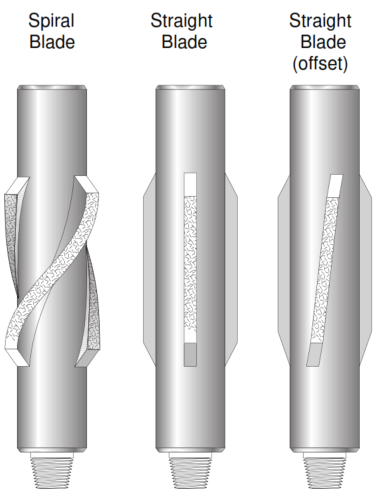

A stabilizer is a piece of down-hole equipment that we use in the Bottom Hole Assembly of a Drill String. It mechanically stabilizes the Bottom Hole Assembly BHA in the borehole to avoid unintentional Sidetracking and drill string vibrations and ensure the quality of the drilled hole. The stabilizer comprises a hollow cylindrical body and stabilizing blades made of high-strength alloy steel. The Stabilizer blades can be straight or spiraled and are hard-faced for wear resistance. Drilling stabilizers have PIN x BOX connections. Furthermore, hard facing is important for the blades to decrease erosion.

They are usually almost the same diameter as the bit and are located in a drill string at various points in the drill collars of the BHA, including just above the bit. Near-bit stabilizers are recognizable by the box/box connection to accommodate the pin connection of the bit. Normally, we position the blades near the bottom, i.e., as close to the drilling bit as possible. The box on the bottom has a “Regular” (Reg.) thread corresponding to the thread used on the bits.

Drilling Stabilizer Applications

- String stabilizers are mandatory for centralizing the Drill Collars in the hole.

- As stabilizer numbers increase in the Drill String as its stiffness or rigidity increases, it increases the ability of the Drill Collars to drill a smooth and straight hole. It reduces the undesirable Drilling Bits movement, such as bit wobble or bit whirl, which reduces bit life.

- It has a great effect on reducing the possibility of differential sticking problems.

- Also, because of the large diameter of the stabilizer, it will provide some reaming action and wipe the walls of the hole to ensure a full-gauge hole. In addition, the reaming action will decrease doglegs and keyseats problems.

- Control deviation while in directional drilling. In such a case, 360 wall coverage (in plan view) is preferable.

What Are The Major Types Of Stabilizers In Drilling String?

The major types of string stabilizers:

- Welded-blade type

- Spiral Stabilize

- Sleeve-Type Stabilizer

- Replaceable Wear Pad

- Non-Rotating type

- Clamp-on Type

- Andergauge

Welded-Blade Stabilizer

The blades of this stabilizer are welded on the body with special methods that guarantee minimizing its failure and increasing its lift time. Many oil and gas companies don’t recommend using such stabs in hard abrasive formations as fatigue and failure are highly likely. This could cause junk-in-hole problems and further fishing operations. We can use this type in straight or spiral string types.

The Steel Body Spiral Stabilizer

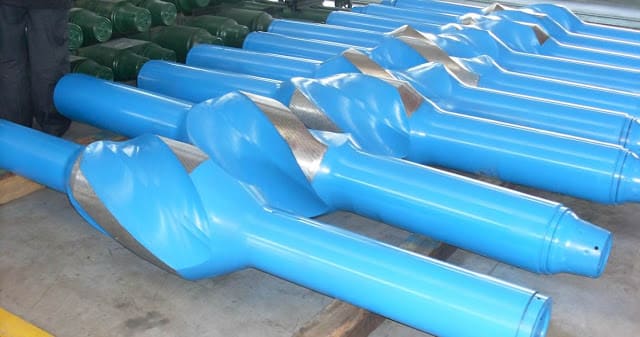

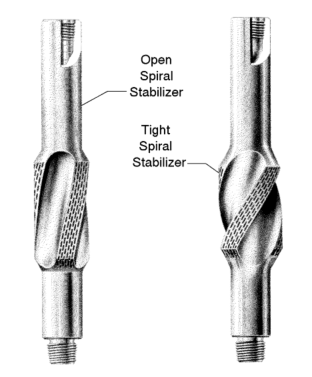

This stabilizer has wings or blades that are integral to the stabilizer body. The blades make 360-degree contact with the wellbore. The outer surfaces of the blades are curved to fit the curvature of the wellbore wall. This bearing surface provides borehole wall contact and permits the stabilizers to hold the Drill Collar assembly centered in the hole.

There are two types of spiral blade Drilling stabilizer Designs:

- The integral blade stabilizer: The blades of this one-piece construction stabilizer are an integral part of the body. When the integral stabilizer wears down to an unacceptable condition, we must send it to the shop for a complete reconditioning. Its design usually has tungsten carbide inserts. That’s why this one is suitable for hard and abrasive formations. It is used in small hole sizes. In addition, They can have either four or three blades.

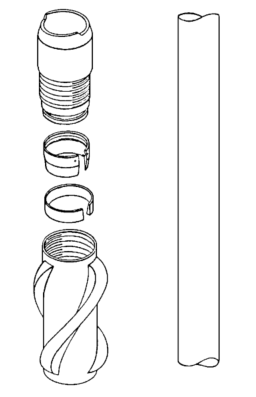

- The replaceable sleeve stabilizer consists of the mandrel and the spiral sleeve. If the blades wear out, you can detach the sleeve from the mandrel and replace it with a reconditioned or new one. This is a great option for large holes.

Sleeve-Type Stabilizer

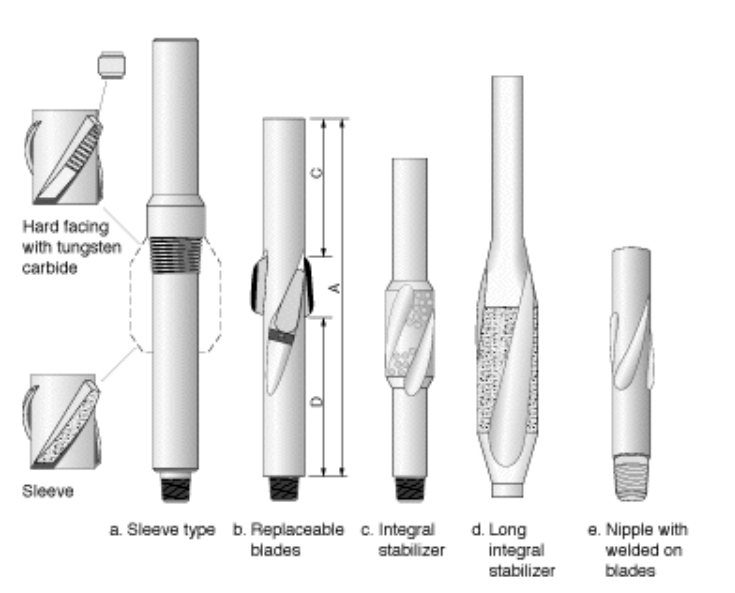

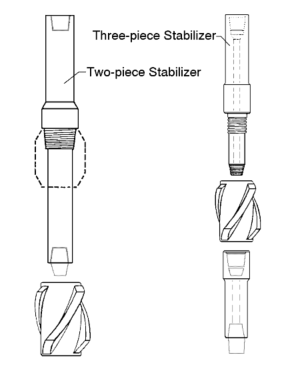

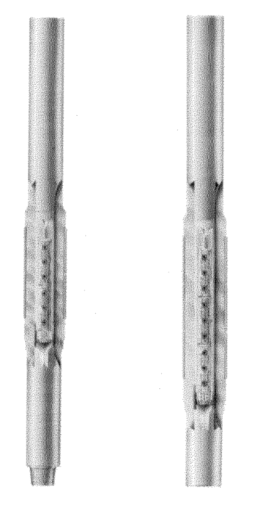

There are two main designs of sleeve-type stabilizers (Figure below).

Have you heard of a two-piece stabilizer? It’s a fascinating tool used in drilling operations that consists of a mandrel and a sleeve. The sleeve is screwed onto the coarse threads on the outside of the mandrel and torqued up to the recommended value. It’s interesting to note that the sleeve’s makeup torque is quite low, and there is no pressure seal at the sleeve. This stabilizer design is widely used today because it allows for easy sleeve changes on the drill floor and several companies manufacture it.

The stabilizer is made up of three parts: mandrel, sleeve, and saver sub. First, you screw the sleeve onto the mandrel by hand. Then, you screw the saver sub into the mandrel and tighten it to the recommended value. It’s important to remember that there is a mud pressure seal at the mandrel/saver sub connection and the makeup torque of this connection is the full value for that size of API connection. To avoid washouts, it’s important to clean and apply dope to the shoulders properly and use the correct makeup torque. However, changing or servicing the sleeve may be challenging and time-consuming. That being said, this type of sleeve-type stabilizer design is not as commonly used today as it was in the past.

The Replaceable Wear Pad (RWP) Stabilizer

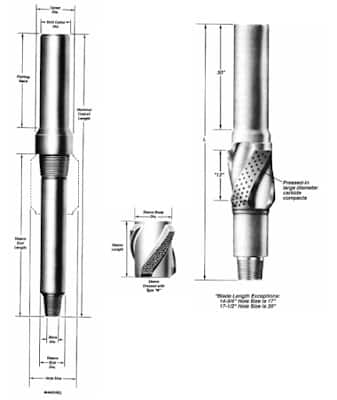

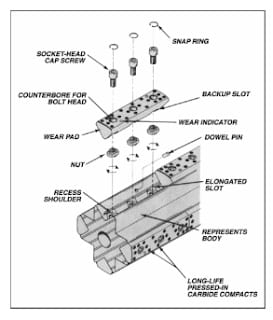

This type of stabilizer consists of four 3 ft long vertical (straight) replaceable pads. Large diameter, pressed-in tungsten carbide compacts on the pad’s surface prolong wear and keep the stabilizer in gauge. The long pads provide a large contact area, which makes the stabilizer suitable for areas of extreme deviation tendencies. The wear pads can be changed easily at the rig. The stabilizer may be resized to a different hole size by replacing the pads with a set that has been manufactured to a different diameter.

The RWP drilling stabilizer Design is good for deviation control. However, the RWP drilling stabilizer is difficult to wash over because of the inserts used. Its longer pad length generates higher torque than the spiral drilling stabilizer.

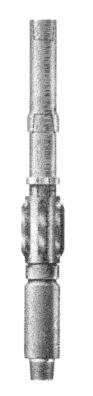

The Non-Rotating Stabilizer

Non-Rotating Drilling Stabilizer Design consists of a mandrel and a polyurethane stabilizer sleeve, which is free to rotate on the mandrel Since the polyurethane stabilizer sleeve does not rotate during drilling (only the mandrel rotates).

The non-rotating drilling stabilizer design reduces drilling torque by employing the ease of rotation between the polished mandrel and the polyurethane sleeve. Its use is common in very large hole sizes where spiral high-strength steel drilling stabilizers would generate excess torque.

Nonrotating drilling stabilizers Design are rarely used as near-bit stabilizers because their radial stiffness is no more than the drill bit itself. Rather, they have used two or three collars above the drilling bit.

The advantages of the non-rotating stabilizer are low cost and low torque and drag. The disadvantages include low radial stiffness, rapid wear and tearing of the urethane pads, and inability to ream under-gauge holes.

Clamp-On Drilling Stabilizer

The Clamp-On types are devices that help in maintaining directional control while drilling a well. There are different types available in the market, including REED, Servco-Loc, and EMTEC. In Figure 5-8, you can see an example of one design. Clamp-on stabilizers are more flexible when it comes to designing the Bottom Hole Assembly (BHA). They can be positioned on Non-Magnetic Drill Collars (NMDCs), Measured While Drilling (MWD), Positive Displacement Motors (PDMs), etc. at the required spacing to maintain directional control. Non-magnetic clamp-on stabilizers are also available if requested. However, some clients may hesitate to use clamp-on stabilizers because they could shift position downhole and may be challenging to remove after pulling out of the hole (POOH).

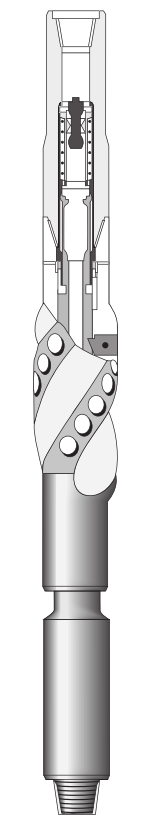

ANDERGAUGE Stabilizer

The ANDERGAUGE stabilizer is a handy tool you can adjust while still downhole. It’s pretty easy to use – you can set it to one of two positions: open (full gauge) or closed (under gauge). To expand it to its full gauge position, you just need to slack off a small amount of weight-on-bit, and then lock it in place with a hydraulic latch. When you must stop using it, simply cut back on the pumps before pulling it off the bottom. When the normal pump rate is resumed, the hydraulic latch locks the stabilizer in the closed position.

BHA design