In General, the Bending Strength ratio BSR is the ratio of the relative stiffness of the box to the pin for a given connection. The predominant consideration, especially in selecting larger Bottom Hole Assembly BHA connections, is (BSR). In Drill String Design, If we select a connection with either a pin or box that is out of balance with the other member, we tend to increase the stress level and accelerate fatigue in the weaker member. In this article, we will discuss its recommended ranges. Also, you can download the bending stress strength ratio calculator.

Bending Stress Ration Ranges

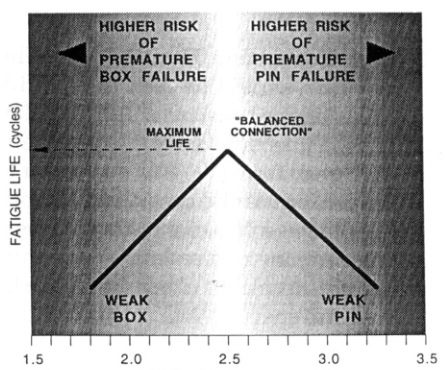

The traditional target BSR is 2.5 and acceptable Bending Strength Ratio‘s ranges center on this point. However, BSR ranges are rough guidelines established by “experience” and should not be used as strict operating limits such as (for example) drill pipe tube tensile capacity. Staying within recommended BSR guidelines does not eliminate connection fatigue failures, nor does exceeding the recommended ranges always lead to fatigue failures (Drill String Failure).

High & Low Bending Strength Ratio

Theoretically, high bending stress ratios should cause accelerated pin failure, and low BSRs should cause accelerated box failures. A balanced BSR should provide maximum connection life. However, field experience shows that larger OD Drill collars sizes (8 inches and up) suffer predominantly from box fatigue cracks even when operating at or near the ideal BSR of 2.5.

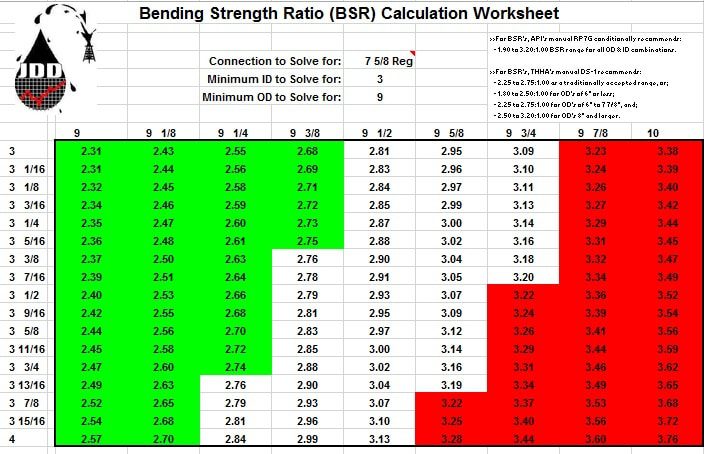

This indicates that a higher BSR Bending Strength Ratio may be appropriate for these sizes. On the other hand, 4.3/4 inch collars with bending stress ratios as low as 1.8 are widely used but rarely experience box fatigue cracks. Therefore, the suggested BSR ranges in Table 5.1 are probably better. In every case, however, experience under given conditions should be a major determinant in BSR selection.

| Drill Collar OD | Traditional BSR Range | Suggested BSR Range |

| Less than 6 inches | 2.25 – 2.75 | 1.8 – 2.5 |

| 6 – 8 inches | 2.25 – 2.75 | 2.25 – 2.75 |

| More than 8 inches | 2.25 – 2.75 | 2.5 – 3.2 |

One frequently overlooked connection is the one between the top drill collar and the bottom joint of Heavy Weight Drill Pipe HWDP. If a straight (non-bottleneck) crossover sub is used and the collar OD is larger than the HWDP tool joint OD, the resulting Bending Strength of that one connection will be exceedingly high. Pin failures in the bottom joint of HWDP are not uncommon, which is the probable reason. The problem is helped by using a bottleneck sub to smooth the change in cross-section.

Bending Strength Ratio Calculator Spreadsheet

Download the Bending Strength Ratio Calculator From the Spreadsheet website.

Can you email me a copy of the BSR spreadsheet? My companies computer is blocking the site.

ok