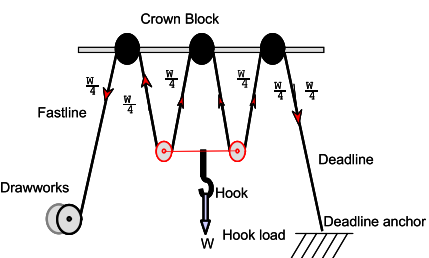

The Crown Block is one of the rig components (hoisting system) composed of a fixed set of pulleys (called sheaves). The location of this stationary block is mainly at the top of the rig derrick or drilling mast, where the drilling line is threaded.

The companion blocks to these pulleys are the traveling blocks. Using two block sets has a tremendous mechanical advantage as this will enable a relatively small drilling line to hoist loads many times heavier than the cable could support as a single strand.

The Crown Block, Travelling Block, and Hook are built following API specifications 8A or 8C.

API Recommendations

Crown Blocks Applications & Mechanism

The crown block also provides a means of taking the drilling line from the hoisting drum to the traveling block. That’s why it is stationary and is firmly fastened to the top of the derrick. The drilling line is reeved around this block, and the traveling block sheaves with the end line going to an anchoring clamp called “DEADLINE ANCHOR.”

The static line is called the deadline. The line section connecting the drum with the crown block is called the fast line. Hence during hoisting operations, if there are ten lines between the crown and the traveling block, the fast line travels ten times faster than the traveling block to spool or unspool the drilling line from the hoisting drum.

Crown Block Specifications

Sheave Characteristics

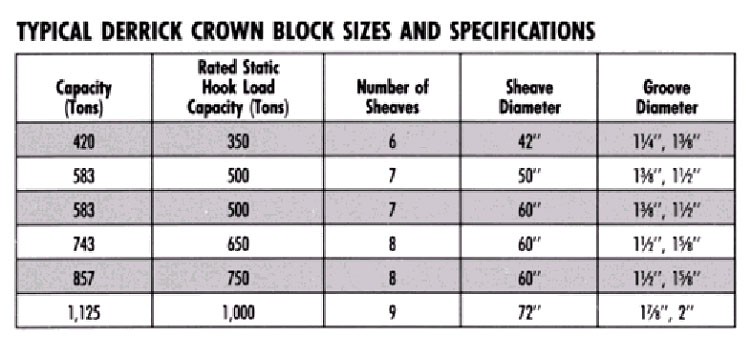

- The ratio of the diameter of the sheave to the drilling line diameter should be between 30-40.

- The number of sheaves on the two Blocks (Crown and Travelling ) can range from 5 to 8 and is a function of the Hoisting system capability.

- The rating of the Crown Block must be higher than the Travelling Blocks. The diameter and the groove of sheaves depend on the diameter of the drilling line. According to API RP 9B, the builder can establish these values.

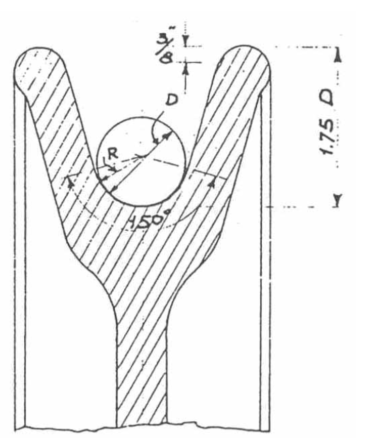

Groove size

The groove on the sheaves must be the same size as the diameter of the drilling line used to provide the proper support.

A groove too wide will flatten the drilling line, while a groove too narrow will cause high friction and excessive wear on the drilling line.

Crown Block Inspection

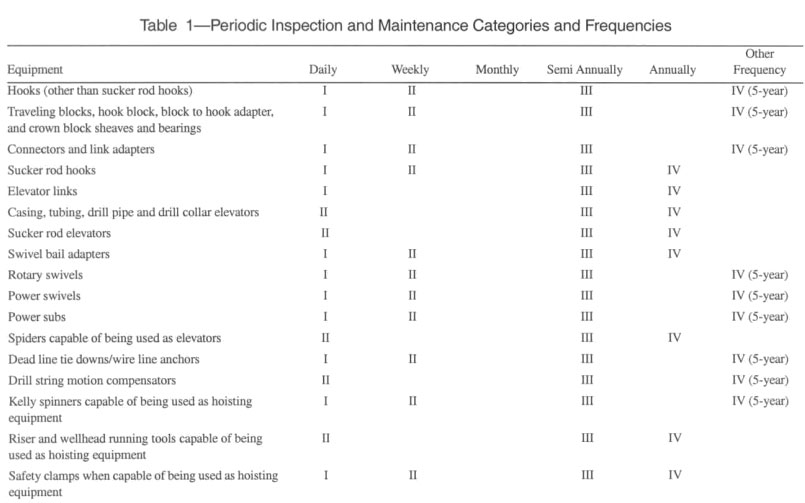

As with all hoisting equipment, the Crown Block must have periodic inspections according to the builder’s recommendations and API RP 8B. The standard procedures stipulate that the Crown Block be certified every five years, in addition to the mandatory periodic inspections.

The frequency of periodic inspections is as follows:

- Daily

- Monthly

- Semi-annual

- Annual

- Five-year

- Table: Periodic Inspection and Maintenance Categories and Frequencies

Inspection Categories

- Category I: Observation of equipment during operation for indications of inadequate performance.

- Category II: Category I inspection, plus further inspection for corrosion, deformation, loose or missing components; deterioration; proper lubrication; visible external cracks; and adjustment.

- Category III: Category II crown block inspection, plus further inspection, which should include NDE of exposed critical

- areas and may involve some disassembly to access specific components and identify wear

- that exceeds the manufacturer’s allowable tolerances.

- Category IV: Category III inspection, plus further inspection where the equipment is disassembled to the extent necessary to conduct NDE of all primary load-carrying components as defined by the manufacturer.

Frequency

The owner or user of the equipment should develop his own schedule of inspections based on experience, manufacturer’s recommendations, and consideration of one or more of the following factors:

- environment;

- load cycles;

- regulatory requirements;

- operating time;

- testing;

- repairs;

- remanufactured

As an alternative, the owner or user may use Table 1.

Final Words

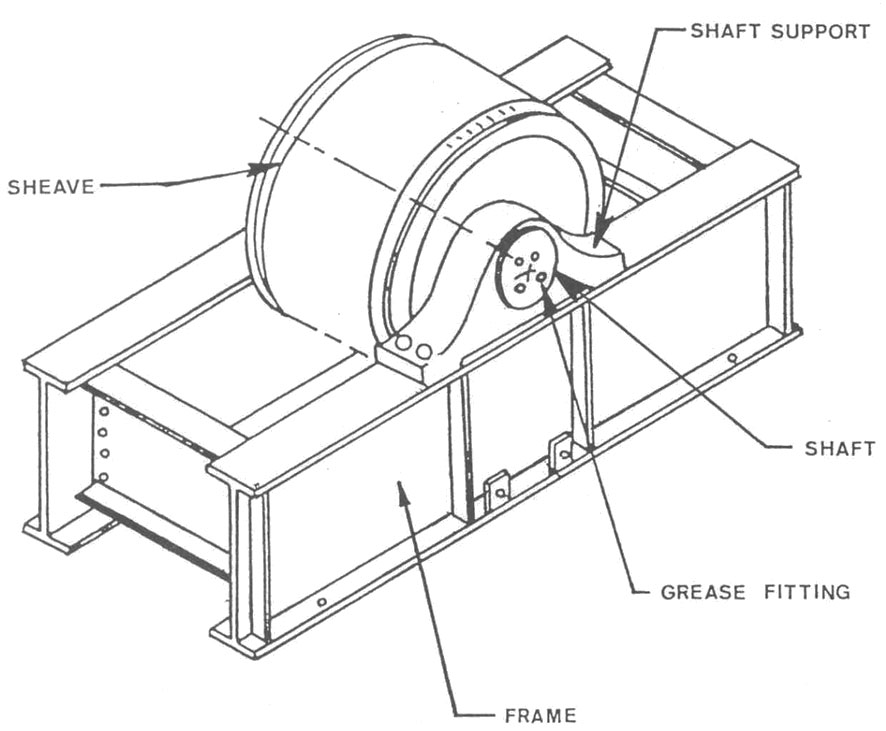

- It is recommended that lubrication of crown block sheaves be done at least once a week. The lubrication is done by pressure lubrication through individual passages drilled in crown shafts.

- While raising and lowering the mast, we should Inspect all the block sheaves for free rotation.

- Install crown block warning devices to prevent running into it.

References:

- Eni Rig Book

- Well Engineering and Construction Book