A multiple completion is one where we can produce several different reservoir zones through separate flow paths within the same wellbore. As we shall see, we may accomplish this with tubing/annulus flow, multiple tubing strings, or by cementing several independent tubing strings in the same wellbore (a multiple tubingless completion).

Reasons For Multiple Completions

A multiple completion is one where we can produce different reservoirs through separate flow paths within the same wellbore. As we shall see, we may accomplish this with tubing/annulus flow, multiple tubing strings, or by cementing many independent tubing strings in the same wellbore (a multiple tubingless completion).

- Higher production rates and faster payouts – This is the most common reason for multiple completions. Several productive zones in a well may have varying productivity indices. When these variations are significant, the weakest interval usually will produce at a higher rate if it is segregated than if it is commingled with the better zones.

- Separating different types of reservoirs – It is generally considered undesirable to commingle oil from a water-drive reservoir with oil from a dissolved-gas-drive reservoir because the pressure decline curves differ. Similarly, oil and gas zones should typically not be commingled in a common wellbore.

- Proper reservoir control – This can be important in primary and secondary operations. In gas-cap drive or water-drive reservoirs having several pays, proper exploitation may require that the different zones be produced at controlled rates to recover the maximum amount of oil. In secondary recovery projects, it is often advisable to inject gas or water into the various pays at controlled rates to maximize oil recovery. It may also be advantageous to multi-complete critical wells to monitor reservoir behavior.

- Other reasons may include government regulations, the need for accurate production history from each zone, price differentials between crudes, etc.

Multiple Zone Completion Disadvantages

While multiple completions are helpful in many situations, they are more costly than single completions. In the case of tubing/packer completions, they increase the risk of equipment failures and the need for fishing jobs. Where all zones have short flowing lives, it is often more practical to commingle all zones on initial completion or to complete in only one zone and open the others on later workovers. Therefore, if commingling production does not violate governmental regulations, result in a substantial reduction in the producing rate, or adversely affect the ultimate recovery, a single commingled completion should be preferred to a multiple completion.

Multiple Zone Completion Types

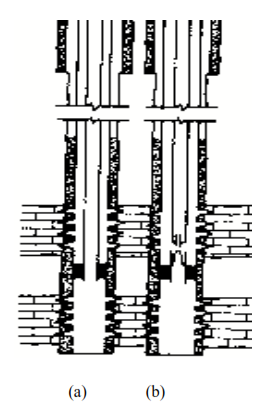

Single String, Single Packer

Figure 1 depicts a multiple completion employing only one tubing string and one packer. We can produce wells in this manner in two different ways. First, the lower zone may flow up the tubing while producing the upper zone up the annulus – Figure 1a. The alternative method (Figure 1b) is to set a plug in the tubing string below a communication device, such as a sliding sleeve or side-pocket mandrel, thereby blanking off the lower zone. Then, by manipulating the communication device, we could produce an upper zone up the tubing.

Figure 1. Multiple Completions : Single String, Single PackerAs you can see, the distinction between single and multiple completions gets somewhat hazy. If we plan to produce both zones simultaneously, it is a multiple completion. However, sequentially producing each zone through the tubing string becomes a single selective completion.

- We can not produce the upper zone through tubing unless blanking off the lower zone.

- The casing is subject to pressure and possible damage by corrosive fluids.

- We can artificially lift only the lower horizon.

- Sand production from the upper zone may require a washover operation to pull the tubing.

- We must kill both zones if we plan to work over the upper zone or if a concentric-type workover is not feasible in the lower interval.

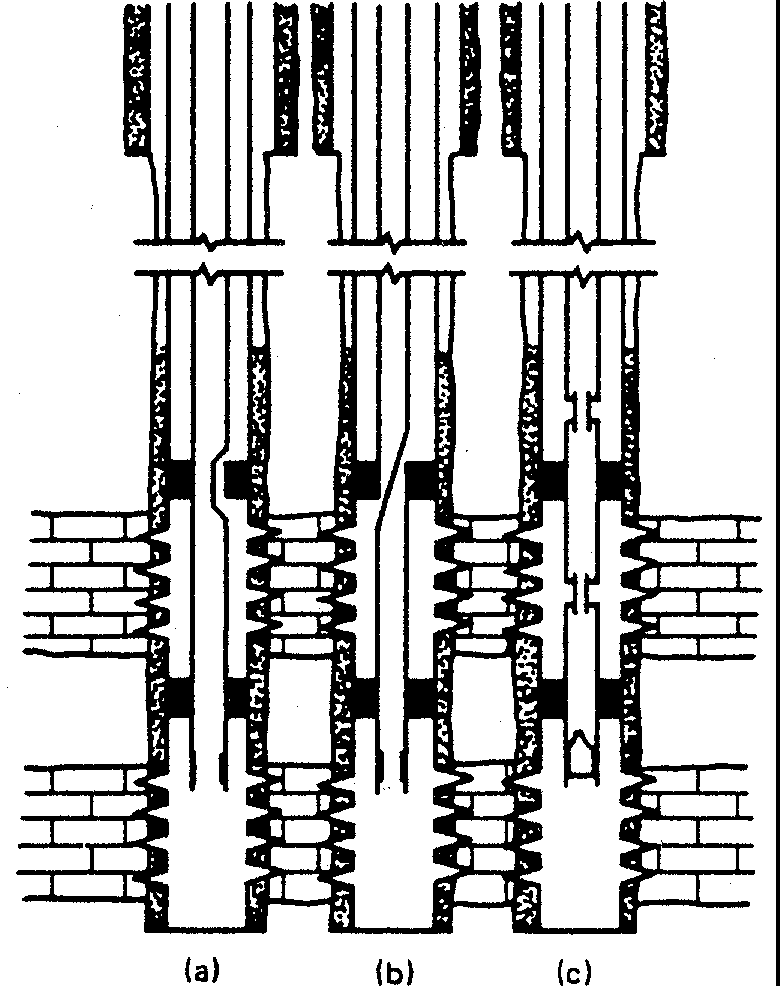

Single String, Multiple Packer Zone Completion

The addition of a second packer can increase the flexibility of dual completions. Figure 2a – illustrates a well with a wireline-retrievable straight-flow choke installed to produce the upper zone through the annulus and the lower zone through the tubing. Crossoverflow chokes (Figure 2b) permit producing the upper zone through the tubing and the lower zone through the casing-tubing annulus. But, the upper zone will flow through the tubing owing to the increased fluid velocity at the same producing rate. Crossover chokes permit this flexibility and artificial lift of the upper zone.

Figure 2. Multiple Completions : Single String, Dual PackerThe arrangement overcomes some limitations of the single-packer type of dual completion; however, it is still impossible to artificially lift both zones simultaneously. Also, the casing is subject to damage by high pressures or corrosive fluids, and it is still necessary to kill both zones to work over the upper zone. The installation of crossover equipment also presupposes that the lower zone will flow on the casing; if it will not, dual selective crossover equipment serves no purpose.

Figure 2c shows a multiple selective single completion, which allows producing several different zones sequentially up the tubing string.

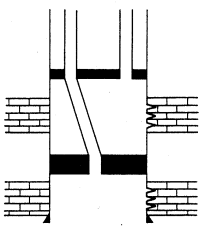

Multiple String, Multiple Packer

The most popular type of multiple completion comprises multiple parallel tubing strings and multiple packers. Figure 3 shows an example of such completion. Installations employing parallel tubing strings allow each zone to flow up a separate conduit, which keeps potentially corrosive high-pressure fluids away from the production casing. They also permit artificial lifting in several zones.

Wireline tools provide circulation between the tubing strings and the casing tubing annulus. Concentric tubing and wireline workovers are also possible with this type of completion.

In most cases, a multiple zone completion consists of a single permanent lower packer and a dual retrievable upper packer. If several different zones exist in the lower section of the hole, it is often desirable to set the lower packer above all of them. Then, each zone can be sequentially depleted using concentric techniques to perforate, squeeze perforations, reperforate higher, etc.

Figure 3. Completions : Parallel String, Multiple PackersIn the past, there were a lot of trials for Multiple concentric completions, but they have proved to be very complex completions with a high risk of mechanical failure. Figure 4 shows an example of such completion. Although the drawing looks simple, there are numerous difficulties associated with running and servicing such a completion.

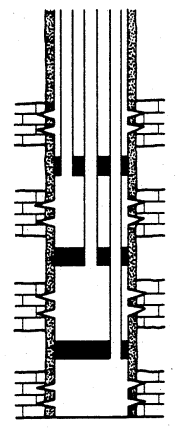

Figure 4. Multiple Completions : Multiple Concentric Tubing StringsFor similar reasons, we seldom un multiple parallel completions with more than two tubing strings. Consider, for example, Figure 5. This completion is mechanical for similar reasons; we seldom run multiple parallel zone completions with more than two tubing strings. Consider, for example, Figure 5. This completion is a mechanical.

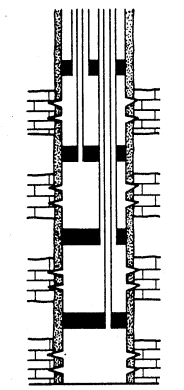

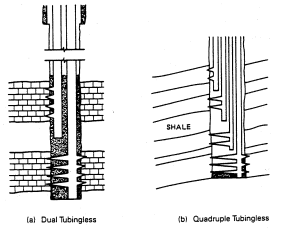

Multiple Tubingless

The multiple tubingless completion is characterized as having two or more strings of tubing run through different intervals. And then we can cement them in place. In theory, this leaves many separate strings which simply share a common wellhead and wellbore. Figures 6 (a) and (b) are examples of such completions.

While multiple tubingless completions have most of the advantages associated with their single tubingless counterparts, they have severe limitations. One major limitation is the difficulty when attempting to cement multiple tubing strings. Very often, behind-pipe communication or “crossflow” occurs. “Crossflow” generally requires remedial cementing action and often increases the completion cost significantly.

A second disadvantage of multiple tubingless completions is the chance of perforating a neighboring string when perforating the target sand. Usually, magnetic detectors or radioactive sources are used to orient the perforating gun away from the other string (s). However, mistakes happen. This is especially true when perforating long intervals where the tubing strings tend to wind around one another.

References:

- Jonathan Bellarby, 2009. Well Completion Design. Elsevier Science.

- Dass, Chanchal. (2010). DASS Well- A New Concept of Multiple Zone Well Completion. 10.2118/130334-MS.

- Qureshi, Aqib, Gupta, Kushal, Al Ali, Salim Abdalla, Uchiyama, Yoshito, and Rohit Singh Negi. “Multi Zone Smart Well Completions Challenges in Highly Deviated Wells and Its Impact on Well Planning and Field Development.” Paper presented at the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, November 2021.