A fish is defined as any undesirable tool, piece of equipment, or other object found in the cased or uncased wellbore that stops or retards routine operational progress. Fishing in drilling oil and gas wells industry can be defined as any operation required to remove undesirable objects (the fish) from the wellbore.

Fishing requires the use of specialized procedures and equipment to remove, retrieve, or well sidetrack a fish so that normal drilling or completion operations may continue. Almost every fishing job presents special problems requiring proper analysis, creative thinking, and the exercise of good judgment to successfully accomplish the objective. Often, fishing operations jobs require many tools and frequent trips with the work string, which may consume much rig time and can result in high operational costs ( check also oil well drilling well cost per foot).

Reasons For Fishing Operations In Drilling Oil & Gas Industry

Tools and equipment are lost in the hole for a variety of reasons. In drilling operations, common causes of fishing are a result of

- A twist-off or parted drill string,

- A stuck pipe problem,

- Stuck wirline logging tools,

- And lost tools or junk

Which inadvertently fall or are otherwise left in the wellbore. Each of these different types of ‘fish’ require special tools and techniques for retrieval. To explain and discuss all the tools and techniques as applied to the variety of fishing operations would require a large volume; therefore, this discussion of the fundamentals must be limited to the most common problems and the generally accepted methods of retrieval.

The costs and inherent risks when fishing make it imperative that the operations and engineering personnel involved communicating freely. Predictions of the additional cost and risks associated with certain types of fishing operations may make it necessary to change the whole job plan and the final objective.

For relatively simple, straightforward oil and gas fishing jobs such as the recovery of pipe inadvertently dropped or left in the hole, an overshot can be used for a reasonably fast and inexpensive recovery. For a more complicated job such as the recovery of stuck or cemented pipe, or the recovery of several wireline tools – special fishing tools and skills will be required. When cases such as these arise, an experienced fishing tool operator should be considered.

Junk In Hole

Junk lost in the hole is considered to be a frequent cause of fishing operations. There are many possible causes for loose junk to be lost in the hole, however, the most frequent causes are

- The loss of a rock bit cone and bearings

- Hand tools or other miscellaneous objects that are inadvertently dropped from the surface

- The loss of roller reamer parts

- The loss of a hole opener arm and cone

- The loss of an underreamer arm

- The loss of a pilot bit during hole opening operations

If at all possible, the first step in the recovery of loose junk lost in the hole is to identify what it is. This may be readily determined if something has been left in the hole on a trip or has been dropped into the hole accidentally. If the type and configuration of the junk are not known, an impression block should be considered. Once the type and size of the object are determined, a decision can be made if it can be recovered as a single whole piece or whether the object must be milled (junk mill) or otherwise broken up. It is generally preferable to recover the junk whole rather than in pieces, however, this is not always possible.

Parted String

One frequent reason for a oil and gas fishing job results when there are a twist-off and the drill string parts due to metal fatigue. Rough handling, scarring by tong dies, improper make-up torque, corrosion and erosion resulting in a washout in the tube body or cracks that form and enlarge under constant bending and torsional stresses during drilling operations. The most common place for this to occur is at the connection of a drill collar, at a crossover, or drill pipe tool joint where the higher stress level generates a crack.

Connection fatigue is commonly found at the base or thread roots on the box or pin connection. When a box failure occurs, a dutchman (the box end thread) is left still threaded onto the pin end connection and recovered when the parted string is pulled. Although not as common, the drill pipe tube can sometimes fail in a long tear or split.

Surface signs of a twist-off include loss of drill string weight, lack of penetration, reduced mud pump pressure, increased pump speed, reduced drilling torque, and increased rotary speed.

Stuck Pipe and Their Causes

Quite often, circumstances during drilling operations will result in the drill string becoming stuck downhole. Both human error and mechanical string failures can cause this. The recovery of stuck pipe can be a difficult, time-consuming and costly operation, therefore it is desirable to identify the type of sticking so that the most effective method of recovery may be initiated immediately. Further discussion of these sticking causes is provided below:

- Differential Sticking

- Mechanical Sticking

- Undergauge Hole

- Inadequate hole cleaning

- Lost Circulation

- Junk In Hole

- Keyseating

- Crooked Pipe

- Ledges & Doglegs

- Stuck In Cement

Economics Of Fishing

Some fishing jobs can go on for months before the fish is retrieved. After a certain period, however, the cost of fishing operations and lost drilling time become prohibitive. Therefore, a truly successful oil and gas industry fishing job should not only be an operational success but an economic success as well.

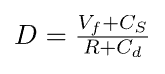

Decisions made during fishing operations should address an economical solution to the problem in the well. Obviously, a shallow hole with little rig time and equipment invested can justify only the cheapest fishing operation. When the lost equipment and tools to be recovered represent a large capital investment, more time and expense can be justified. Generally, once these costs reach about one-half of the cost of sidetracking and re-drilling, fishing operations should be abandoned. One approach used to calculate the number of rig days that should be allowed for fishing uses the following equation:

where

- D = number of days allowed for fishing

- Vf = replacement value of fish

- Cs = estimated cost of sidetracking

- R = daily cost of fishing tool rental and services

- Cd = daily rig operating cost

Avoiding Fishing Operations & Hazards While Drilling

The secret to a successful drilling program is to avoid the hazards (Oil Rig Hazards) that historically have led to fishing jobs.

- Take all precautions to ensure that objects are not dropped into the wellbore.

- Monitor the drilling torque carefully and learn the limitations of the drilling bottom hole assembly .

- Begin with a full inspection (including electromagnetic) of the drillstring and BHA.

- Continue a routine BHA maintenance and inspection program by monitoring operating hours in service. “If indoubt, leave it out”.

- Condition the hole and drilling mud before drilling bit or BHA trips (check also Pipe tripping procedures). Circulate a high-viscous sweep to unload the hole of excessive drill cuttings. If required, spot a high viscous pill on the bottom to adequately suspend solids and contain loose, unconsolidated formation.

- Before drilling into a potential loss circulation zone, circulate a high viscous sweep to unload the hole of excessive drill cuttings and reduce the effective mud density.

- Make routine wiper conditioning trips to gauge the overall hole stability and the condition of possible water-sensitive and tight shale sections.

- Carefully ream out any suspected undergauge hole.

- Formulate a plan to recover a downhole assembly should it become stuck or parted.

- Inventory and inspect all fishing tools that may be required immediately. Order missing or defective parts.

- Can the BHA components be fished? What tools are required?

- Can it be washed over? What tools are required?

Preparation For Fishing Operations In Drilling

Regardless of the cause, the success or failure of the oil & gas fishing job greatly depends on the degree of preparedness taken prior to the commencement of drilling operations. The following factors should be considered when preparing for a fishing job –

Critical Information

The costs and inherent risks of fishing make it imperative that the following critical well information and BHA data be recorded in advance of drilling operations startup. Continue to update the information as required.

| A. CASING/LINER DATA | B. HOLE DATA | C. MUD DATA |

| – Size (OD, ID) | – Size | – Type |

| – Weights | – Depth | – Density |

| – Depths | – Angle | – Reology |

| – Grade | – Condition | – Water Loss |

| – Connection | – Lost Circulation | |

| – Undergauge |

Record every dimension and the position of all drilling tools (as listed below) in the string before they are run below the rotary table. Continue to update the information as required. Maintaining a good record of all critical equipment dimensions is necessary if an economical oil & gas fishing job operation is to be done.

- DRILL PIPE – Sizes (OD, ID) (API Drill Pipe Specs)

- DRILL COLLARS –

- Tool Joint OD

- Weights

- Grade

- Quantity

- Length

- Connection

- Last Inspection?

- STABILIZERS – Size (OD, ID)

- REAMERS Type/Serial No.

- DRILLING JARS – Quantity

- SHOCK SUB – Fish Neck Length

- CORE BARREL – Overall Length

- MUD MOTOR – Connection

- HOLE OPENER – Last Inspection? SUBS

Fishing Preparation Of Hole And Drilling Fluid

The hole should be conditioned (mud conditioning), and the drilling fluid should have the desired mud properties before starting in the hole with fishing tools. It may be necessary to make a trip with a bit to condition the hole and circulate out fill that has covered the fish. Always circulate and flush the hole first with a high viscous pill to unload drill cuttings, and spot a balanced high viscous pill above the fish to suspend solids before tripping out for fishing tools.

Type And Details Of Fish

Once it is evident that fishing operations must be conducted, it is necessary to learn and acquire all relevant information about the fish to be recovered. Determine

- The probable cause of the failure or reason for junk lost in the hole.

- The size, length, amount, and type of fish (all dimensions are important).

- The location or top of the fish. (check also: Free point indicator)

- The condition of the top of the fish.

- The mechanical condition of the wellbore casing.

- The condition and stability of the open hole interval down to the top of the fish.

- The value or replacement cost of the fish if sidetracked and left in the hole.

- The probability of success, risks of failure, and estimated recovery time and cost.