Thru tubing perforating guns is a technique dating from the 1950s. Using a seal around the cable at the surface allows perforating of hydrocarbon wells while there is pressure at the surface. This enables perforation of the well without excessive hydrostatic pressure caused by drilling or workover fluids. Please note that this type is different than wireline conveyed perforating. We think that this article, “Well Perforation Methods” might be interesting to read.

Thru Tubing Perforating Gun Applications

The thru tubing perforating guns can activate additional reservoirs by penetrating multiple production strings and accessing additional production zones without removing the completion string from the wellbore. In addition, there will be no need to get a workover or drilling rig to perform such a job as we can perforate rigless.

Advantages

- Better well control can be achieved due to the packer and tubing being in place during perforation.

- Allows limited underbalance to the formation.

- Packer and completion/DST tools are in the well during perforating.

- Underbalance helps in perforation cleanup.

Disadvantages

- Guns with small outer diameters and small charges will have limited perforation performance.

- There is a need to decentralize the guns to optimize performance.

- Underbalance limitation to around 1000 psi.

- The limitation of perforator length by the lubricator height, positioning device, the added weights to counter the high pressure, and the collar locator.

Types

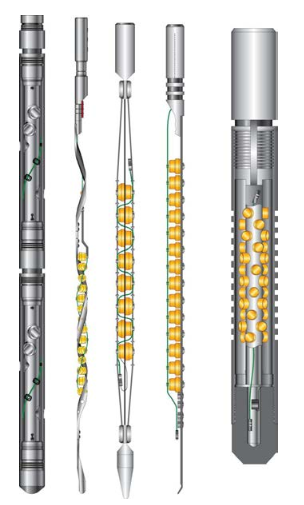

There are mainly three main types of thru tubing perforating guns:

- Guns that use fully retrievable carriers.

- Those using a retrievable carrier strip support charges contained in expendable cases.

- Guns in which charge case and caps break up into small pieces after detonation

Retrievable Hollow Carrier Guns

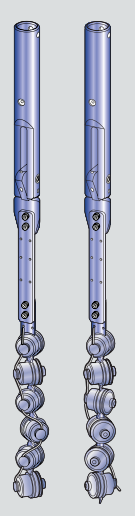

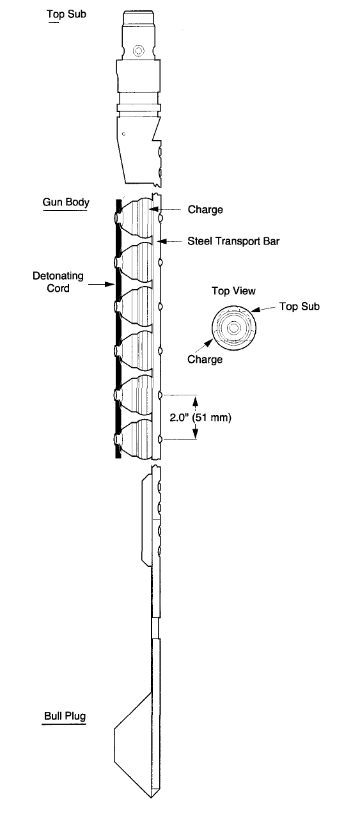

These are smaller versions of casing guns that we can run through the tubing, hence having 180 lower charge sizes and, therefore, better performance than all other guns. They only offer 0 o phasing with a max. of 4spf on the 2 1/8 ” OD gun and 6spf on the 2 7/8” OD gun. Due to the stand-off from the casing that these guns may have, there will be a need for orientation or decentralizing tools.

Hollow carrier guns are available in various sizes ranging from 30 mm (1 3/16″) to 73 mm (2 7/8″) for thru tubing applications. The minimum completion string (Types of completion) ID limits the appropriate gun size. However, the smaller guns up to 54 mm (2 1/8″) have limited power due to their physical size. This restricts the length of the shaped charge liner.

Hence, the jet’s length reduces the number of explosives in each charge. The maximum shot density with these guns is 19 shots per meter (6 shots per foot). We can configure the thru tubing guns to give almost any perforating phasing. The poor penetration of the minor charges fired across the wellbore is likely to offset the reduction in geometrical skin due to phasing.

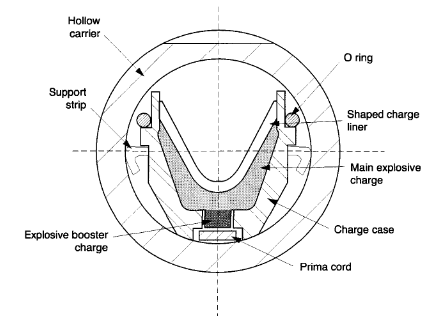

Principle of Work

The guns are generally operated with zero phasing. In addition, we can position the gun mechanically or magnetically to minimize the gap between the gun and the casing pipe. The larger 73 mm (2 7/8″) guns offer performance comparable to that obtained with the smaller expendable or semi-expendable capsule guns. Their penetration performance allows their use in a phased or 360° spiral configuration, reducing geometrical skin and improving inflow performance even when fired across the borehole. Hollow carrier guns minimize casing damage as the carrier contains the force of the explosion and the high-velocity fragments of the shaped charge cases. Figure 3 illustrates the hollow carrier gun cross section.

Hollow carrier guns are more efficient than capsule guns in perforating longer intervals during each run. This is because the weight of the carrier reduces the need for additional weights. However, surface pressure equipment constraints limits the maximum gun length at one time to around 10 meters.

Expendable and Semi-Expendable Thru Tubing Perforating Guns

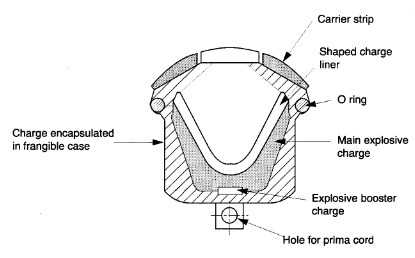

Expendable and semi-expendable guns are available from most perforating service companies under a variety of trade names and range in size from 43 mm (1 11/16″) to 73 mm (2 7/8″). Their performance is generally superior to hollow carrier guns of a similar size. These guns comprise individual-shaped charges, each in a separate pressure vessel supported by wires or carrier strips.

When a gun fires in a well, it shatters the pressure vessels, which could be made of ceramic, aluminum, or steel, into small pieces. Semi-expendable guns can recover the supporting wires or strips, but the expendable capsule guns destroy them and leave them in the well. The high-density debris should fall to the bottom of the well, but the initial surge flow can carry it up. In wells that are highly deviated, friction may prevent the debris from descending into the well, causing steel or other fragmented material to be carried to the surface when the well is produced.

To prevent damage to chokes, sub-surface safety valves, and surface production equipment, it is crucial to take measures to avoid debris. The flow returning to the surface will contain low-density polymer material and fragments of material from the pressure vessel and shaped charge case. These fragments are driven by the force of the explosion and impact on the casing, causing significant damage and accelerating corrosion. To prevent excessive casing damage, you must limit the size of thru tubing perforating guns to 54 mm (2 1/8″).

Cons

The expandable and semi-expandable types of guns are regarded as the most potent among all types. However, the benefits they offer must be considered against the issues that arise due to significant amounts of debris in the wellbore, the likelihood of casing damage caused by the more forceful charges, and the absence of an enclosure to confine the explosion.

Pivot Thru Tubing Perforating Guns

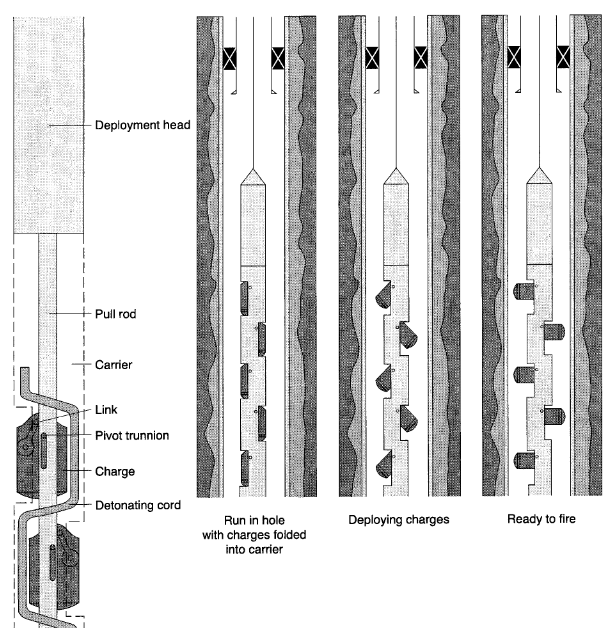

At the end of 1992, Schlumberger introduced a new thru tubing perforating system called the Pivot Guns. The system has a performance comparable to casing guns. It can pass restrictions with diameters as small as 45 mm (1 7/8″) by using large charges assembled in the gun parallel to its axis. When the gun is in-depth, the charges are rotated 90° and then fired Fig. 6.

The improved performance of this fully disposable 43 mm (1 11/16″) gun makes it suitable for use in tubing applications, where the diameter of the production tubing is significantly smaller than that of the production casing. It is particularly useful where effective shot perforation is a crucial design consideration.

Because of the sensitivity of the gun mechanism to well deviation and debris, special running procedures need to be used for this gun, particularly in multiple runs. Schlumberger should be consulted for complete details.