Hollow carrier casing guns are the direct descendants of the original perforating guns that have been in use since the 1930s. These guns are available in diameters from 86 mm (3 3/8″) to 184 mm (7 1/4″). Furthermore, they can contain up to 46 shots per meter (14 shots per foot).

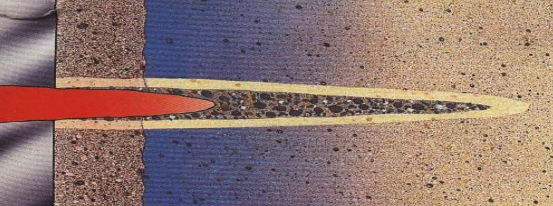

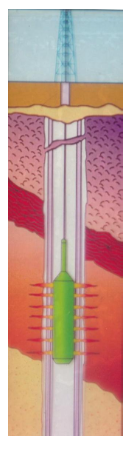

Large-diameter steel carrier casing guns can transport large charges downhole and provide perforation with deep penetration or big entry holes. They are run on a wireline (Wireline Conveyed Perforating). In addition, they are used to perforate in a balanced or slightly overbalanced condition. The hydrostatic pressure holds the formation pressure while the guns are pulled from the well and the production equipment and wellhead are installed. The well is then swabbed to induce flow from the formation. In most cases, stimulating the well by hydraulic fracturing or acidizing is required. This will help achieve the desired production after hydraulically opening the perforation.

Working Principle & Operations

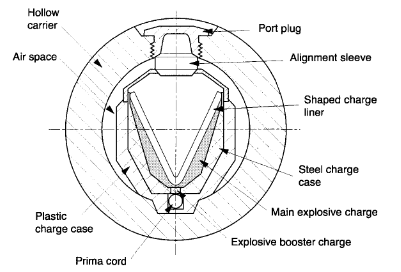

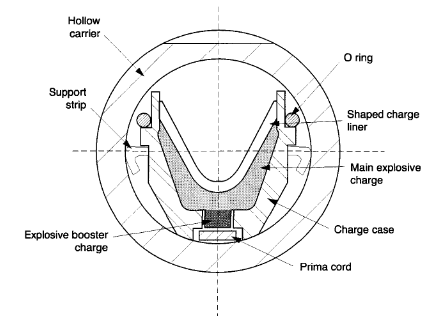

Two main types of casing gun are in use:

- Re-usable casing gun in which the shots are arranged to fire through replaceable porthole plugs (Fig. 1);

- Semi-expendable types where the carrier is perforated and cannot be re-used (Fig. 2).

Although these guns are large enough to hold the largest charge sizes, the performance of perforations is limited by the need to perforate in balanced or overbalanced conditions. These guns offer a full range of phasing options, and their large outside diameters mean that the standoff for shots fired across the hole is not excessive.

For applications requiring large diameter perforation entry holes, these guns can be fitted with extended porthole plugs or standoffs to ensure the gun is centralized within the hole. The maximum length of a gun that can be run at one time is limited by the gun’s weight to about 20 m. This can consist of a single gun or several shorter guns, each of which may be individually fired at a specified depth. These guns can be run through large-diameter completions. With suitable pressure control equipment, they can be used to perforate with slightly underbalanced conditions.

The amount of underbalance that can be achieved is limited by the pressure control equipment available for large cables, which restricts surface pressure to 3.5 MPa (500 psi). This practice has, however, been largely superseded by the use of tubing-conveyed guns. Casing guns are generally run before completing a well, and their use is therefore restricted to initial completion or workover and remedial operations. The weight of these guns means that a large diameter cable is required to run them into the hole, requiring a hoist.

Casing Gun Pros & Cons

Advantages:

- Large O.D. guns with large charges offer maximum performance.

- Perforating costs may be lower than other perforation methods.

Disadvantages:

- Perforating must be done in balanced or overbalanced conditions for safety.

- The length of the perforator is limited to the lubricator length.