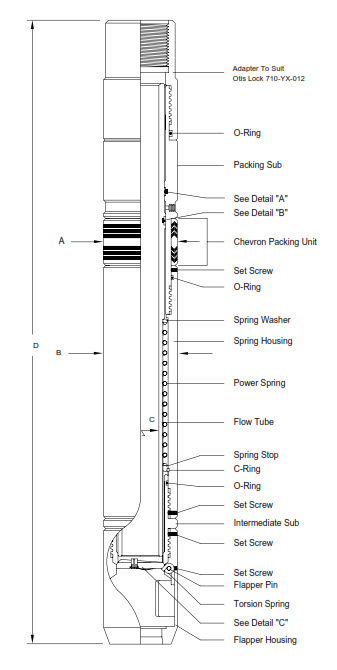

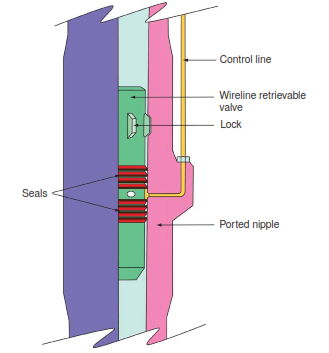

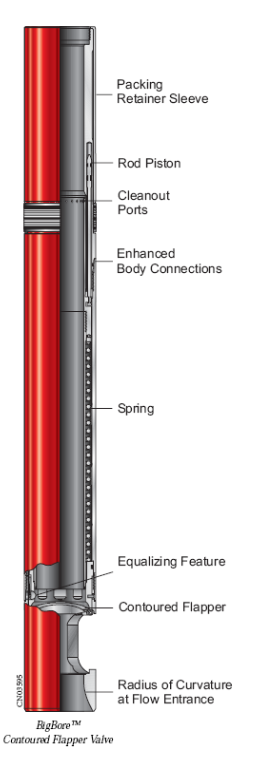

After installation of the completion string, we can run, locate & lock a wireline retrievable subsurface safety valve WRSV into a safety valve landing nipple (SVLN) before production. The SVLN (valve nipple) is integral to the tubing string. The valves typically open due to the hydraulic pressure acting on a piston which moves a flow tube against the ball or through the flapper. On bleeding off pressure, a spring ensures reverse movement of the piston and the flow tube, allowing valve closure.

.

Advantages

- Situations requiring a valve with internal equalizing capabilities can confidently utilize a sacrificial wireline retrievable valve. If the equalizing area is flow cut, the valve may be quickly and inexpensively retrieved and repaired.

- Accessibility: we can install wireline retrievable valves in hydraulic landing nipples, communication nipples, or locked-out tubing retrievable subsurface safety valves.

- We can easily retrieve downhole valves during any workover operations (acidizing or Hydraulic fracturing).

- Wireline valve installation is simple. In addition, we can easily remove them for repair or replacement.

Disadvantages:

- Prior to landing the valve in the tubing, there will be direct contact between the control line fluid and the contaminating fluids in the tubing.

- During installation operations, we should remove the valve. Therefore, there will be no downhole safety valve in the well.

- Installation errors or faulty locks can cause the valve to be loose when closed.

- Installing a WLR valve restricts the inside through diameter of the tubing and, therefore, will affect the production rates.

Required Tools For Installing WRSV

The components required to install a wireline retrievable safety valve (WRSV) system are;

- WRSV.

- SVLN.

- Lock mandrel.

- Hydraulic control line and fittings.

- Hydraulic control manifold.

- Wireline installation and retrieval tools.

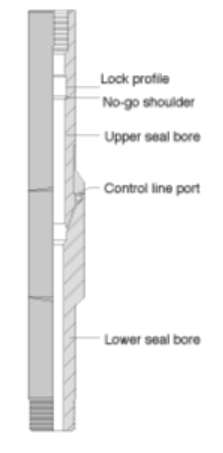

Landing Nipple For Wireline Retrievable Subsurface Safety Valve

A safety valve landing nipple is a short tubular component primarily designed as a receptacle to lock the WRSV. It is run on the production tubing string. The main features of an SVLN are the control line port, locking groove or profile, polished seal bores above and below the control line port, polished seal bore below the control line port, and no-go shoulder. The figure below illustrate such features.

The internal locking profile receives the matching keys of the appropriate lock mandrel to which the WRSV is assembled. This assembly is run, located, and locked into the SVLN. The control line port in the SVLN exits through a lug which, being raised, offers a degree of protection for the hydraulic control line and its fitting. In general, SVLNs are usually of a non-welded construction designed to be robust against shock and knocking while installed. The material selected for the SVLN must resist the corrosion effects of the well environment.

SVLNs are available in various configurations depending on the WRSV design, tubing weight, and thread connection.

Control Lines

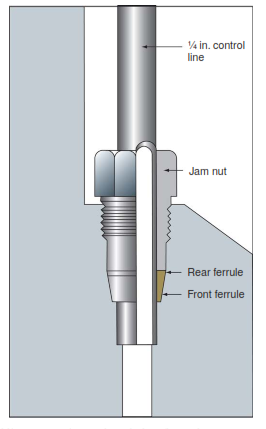

Compression fittings attach the control line to the SVLN and tubing hanger. The material selected for these must be compatible with the nipple and hanger materials and also resistant to annulus or corrosion by packer fluids. (also check Types of packers)

Lock Mandrel For Wireline Retrievable Subsurface Safety Valve

A lock mandrel, as stated earlier, is a carrier for the WRSV and is a removable locking device used to locate, lock and seal off within the matching SVLN. The WRSV is attached to the lower end of the lock mandrel to make up the subsurface safety valve assembly.

The lock mandrel keys are mechanically driven out and locked into the internally machined recess of the SVLN.

Wireline Installation And Retrieval Tools For Safety Valves

When running a WRSV, a prong on the running tool (R/T) of the wireline tool string will be useful to hold the valve in the open position and further allow fluid bypass when entering the nipple; otherwise, it would become pressure locked. When there is a successfull lock into the SVLN, we can apply hydraulic pressure to the control line to hold the valve open, allowing retrieval of the prong, R/T, and tool string.

We can achieve pressure sealing within the nipple by packing stacks on the lock mandrel and the WRSV, which positions in the landing nipple’s upper and lower seal bores. This packing stacks seals above and below the control line port within the nipple. The area between the packings is the communication path from the control line into the valve operating system. Control fluid from the control line, usually 1/4″ OD tubing, enters the valve’s hydraulic piston and actuates the valve.

Other Tools For Enhanced Safety Installation

- Running Tool shall have control shear pins.

- On the mandrel, the locking dogs are physically blocked at the end of the setting operation by a sliding safety sleeve (Sliding Sleeve) that keeps them from retracting.

- Proper positioning of the safety sleeve is indicated when the control pin is sheared on

the running tool.