Production packers are generally classified as either retrievable or permanent types. By definition, a retrievable packer can be removed from a well by tubing manipulation, or some other means not involving the destruction of the packer. But to remove the permanent packer, we shall work on milling or destroying it. That’s why we refer to permanent packers as drillable packers. A classification outline of production packers is shown below.

- Permanent

- II. Hook Wall Retrievable

- Compression

- Mechanically set

- Hydraulically set

- Tension-mechanically set

- Tension and compression

- Compression

- Special Retrievable Packers Type

- Cup

- Inflatable

- Permanent-retrievable (Seal bore retrievable packers)

The primary function of any packer is to provide a seal – the crucial prerequisite to be met in the packer selection. All other considerations are of secondary importance, and quite rightly so. Before deciding which packer will be selected, full knowledge of the functions expected of the packer, the environmental working conditions, and its mechanical design is a must.

Packers Classification System

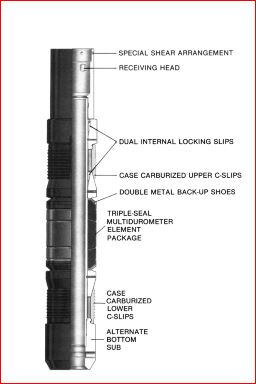

The primary method of classifying packer types concerns their permanency in the hole,i.e., whether the packer is retrievable or permanent. From its name, the retrievable packer can be unset and retrieved from inside the casing normally by manipulation, which permits the reverse of the packer setting. The design of the permanent packer Figure 3 allows it to remain in the hole, and although it can be retrieved from the hole, the unsettling process is more complicated as it is not the reverse of the setting process.

But there is another characteristic of a production packer that is called the completion string stress state, i.e., whether it is set in tension, compression, or in a neutral state(check also: Neutral point). This stress state could apply at the time of setting, but following P or T impacts during production could generate a significant change in the stress state.

The third characteristic is the nature of the packer setting mechanism, which is used to compress the sealing element system.

Packers Types According To Their Applications

Packer application with regard to completion design is addressed in this section as there are some basic features that affect the completion architecture.

Although there are many varieties of packers available, there are three basic classes used in completion designs:

- Permanent

- Retrievable

- Permanent Retrievable.

Many oil and gas companies do not have any special procedure on the types of packer system to be used in a certain situation as there is a great range of packer types due to technology advancements.

Retrievable Packers Type

We can define the retrievable type as it is the packer that can be installed and retrieved with mechanical or hydraulic mechanism. They have advantages as they could be installed in highly deviated wells although their operating differential P rating, T rating, and bore size are less than equivalent permanent type. It is a must that designers fully consider the impacts of pressure and tubing stresses on these packer systems and related packer-string connections. Their rubber elements are also more sensitive to well fluids as they are more complex due to their ability to be retrieved but after redressing they can be re-used.

The major applications for retrievable packers”

- Completions that have a relatively short life span. Check also (open hole completion)

- Where there are likely to be workovers requiring full bore access.

- Multi-zone completions for zonal isolation.

- In relatively mild well conditions.

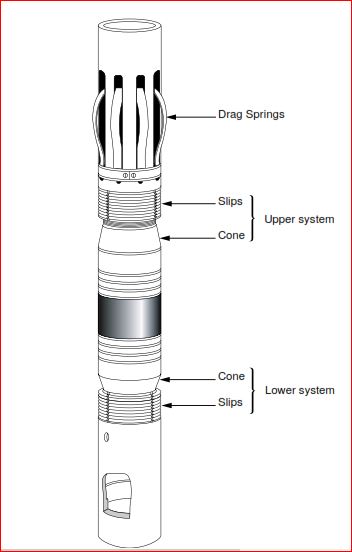

The setting mechanisms for retrievable packers type:

- Tubing tension

- Tubing compression

- Hydraulic pressure

- Tubing rotation.

Tension or compression mechanisms are very sensitive to tubing movement and nowadays they are seldom due to the advantages and variety of other retrievable packers available.

Permanent Packer Systems

A permanent type can be defined as a packer that can be retrieved from the oil and gas wells only by milling. Permanent packers type has high differential P and T ratings and larger bores than the retrievable one. They have many choices of both tailpipe and other attachments to cover a wide range of applications such as:

- Extreme conditions with differential P > 5,000psi and T in excess of 300 degrees F and high stresses.

- Long life completions.

- Where workovers are expected to be above the packer, hence not requiring its removal which is costly.

- Where workovers are expected to be above the packer and the packer tailpipe can be utilized for plugging the well and isolating foreign fluids from the formation.

- Providing large bore for high rate wells.

The major setting mechanism for the permanent packer are:

- Wireline explosive charge setting tool.

- Tubing tension.

- Hydraulic pressure by workstring setting tool or on the completion string.

- Tubing rotation.

Permanent Retrievable Packer Systems

The permanently retrievable packers are a combination of the permanent style packer designed to be retrieved on a workstring without milling. They offer a similar design as permanent packers but generally have smaller bores.

All the packers above can be furnished with tailpipes to house wireline downhole tools such as plugs, standing valves, bottom hole pressure gauges, etc.

Packers Types According To Their Setting Mechanisms

Electric Wireline Set Packer

The electric line set packer is the most commonly used packer. It can be installed quickly and accurately at the required well depth. After setting the packer, you can RIH with the production seal assembly and production tubing. Once the seal assembly seals into the packer, space out the tubing string and continue completion operations.

Hydraulic Set Packer

There are instances when it is desirable to run an electric line set packer, however, well requirements may prevent using the such mechanism. A hydraulic setting tool may be used to accommodate the running of an electric wireline set packer. it simply takes the place of the wireline setting tool when circumstances so dictate. You can easily M/U & RIH with the packer equipped with the hydraulic setting tool on drill pipes. Once in depth, drop a ball through the string into its ball seat. by using mud pump, pressure activates the setting tool which will set the packer. Then POOH with the hydraulic setting tool and workstring and production seals and tubing is run to complete the well.

Some conditions which may require using a hydraulic setting tool are:

- If there is a previously set lower packer in place, the seals of the running packer will be required to be pushed into that packer using the workstring weight.

- If the weight of the packer and related tools and equipment is more than what electric wireline can handle.

- If the mud weight or viscosity is high and the packer can’t fall with his weight if run on electric wireline. The weight of the pipe may be required to push the packer down.

- As the inclination angle becomes greater, a point is reached where the packer will no longer fall down the well with his weight, which will require using a workstring.

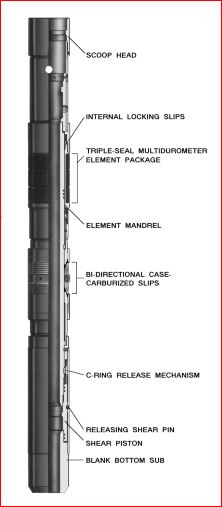

Mechanical Set Packer

The mechanical retrievable packers are designed to be run and set on tubing, released, moved, and set again without tripping the tubing. They can be retrieved, redressed (if necessary), and used again and again. These packers are “ONE TRIP” packers.

There are several types of mechanical retrievable packers based on the tubing movement required to set the packer.

The internal latch type of mechanical retrievable packers is designed to be run on tubing and set by rotating the packer (approximately 1/4 right-hand turn) and then setting weight on the packer. Once set, tubing weight may be left on the packer or spaced out in tension or neutral. The release is accomplished by tubing weight down and right-hand rotation.

Applications for this packer include:

- Testing and zone stimulation

- Production

- Tubing anchor

The mechanical hook wall retrievable packer is designed with many of the same features as the previously mentioned latch packer. However, tension cannot be pulled against this packer. It is run and set on tubing, released, moved, and set again without tripping (pipe tripping) the tubing. They can be retrieved, redressed (if necessary), and used repeatedly.

This packer is normally used for:

- Wells where high differential pressures are anticipated from above and below the packer.

- Production

- Acidizing- hydrofracking, testing, swabbing, and other high-pressure well stimulation and production operations.

Hydrostatic Set Packers

A hydrostatic set packer consists of a regular MHR or AHC permanent packer and a hydrostatic setting module. The packer is set without well intervention (i.e. no plugs or other devices required) using available well hydrostatic pressure and applied surface pressure. The packer has a contingency setting feature that allows it to be set by installing a plug below the packer and setting it by pressuring up the tubing string.

Benefits:

- Reduces packer setting costs

- Reduces rig time

- Uses available hydrostatic pressure

- Reduces the risks of wellbore intervention to set or retrieve packer setting plug

How does it work?

The hydrostatic module, which contains an atmospheric chamber, is assembled to the bottom sub of the packer. Rupture disks are incorporated into the design of the module. Upon application of pressure at the surface to the wellbore, the disks rupture, exposing the hydrostatic setting piston to wellbore hydrostatic pressure. The pressure differential between the atmospheric chamber and wellbore hydrostatic provides the setting force necessary to set the packer.

Where can it be used?

Hydrostatic set packers can only be used before perforating the production casing or in a well in which the casing and tubing string can be pressured up to a predetermined value.

Currently, the absolute pressure at the packer should be between 4,000 and 7,500 psi. Absolute pressure is defined as hydrostatic pressure at the packer plus pressure applied at the surface. The pressure applied at the surface is recommended to be 25% of the hydrostatic pressure at the packer. The 4,000 psi minimum ensures a full-packer set. The 7,500 psi maximum ensures that any collapse load induced on the hydrostatic setting module by the absolute pressure does not bind the module and thus prevents packer setting. For wellbore conditions near these limits, please contact the Global Advisor to determine whether this technology should be used in the completion.