The conductor pipe runs from the seafloor/surface to relatively shallow depths, providing a conduit to allow circulation of drilling fluid and case off unconsolidated formations. It is the first string we use to support well control equipment, typically a drilling diverter. A standard size for the conductor casing pipe is 24″, 26″, or 30″. In addition, we usually set it from 40 m to 500 m below the seafloor/surface. Here, we will discuss conductor casing pipe specifications, connectors, installation, hammering, and running operations in oil and gas wells. We shall also provide conductor pipe specifications sheets.

Conductor casing Pipe supports the wellhead, the weight of all subsequent casing strings and tubing in many wells, but there are many other wells where the conductor plays no role as a structural member. It maintains borehole integrity through the usually soft formations. It seldom gives us any pressure control because the shallow formations at the setting depth often have little strength. Hence, its role in maintaining borehole integrity is relatively short-lived and severely limited.

As conductor casing pipe is considered one of the Types Of Casing, its specifications are the same as casing specifications.

Conductor Casing Pipe Specification In Oil and Gas

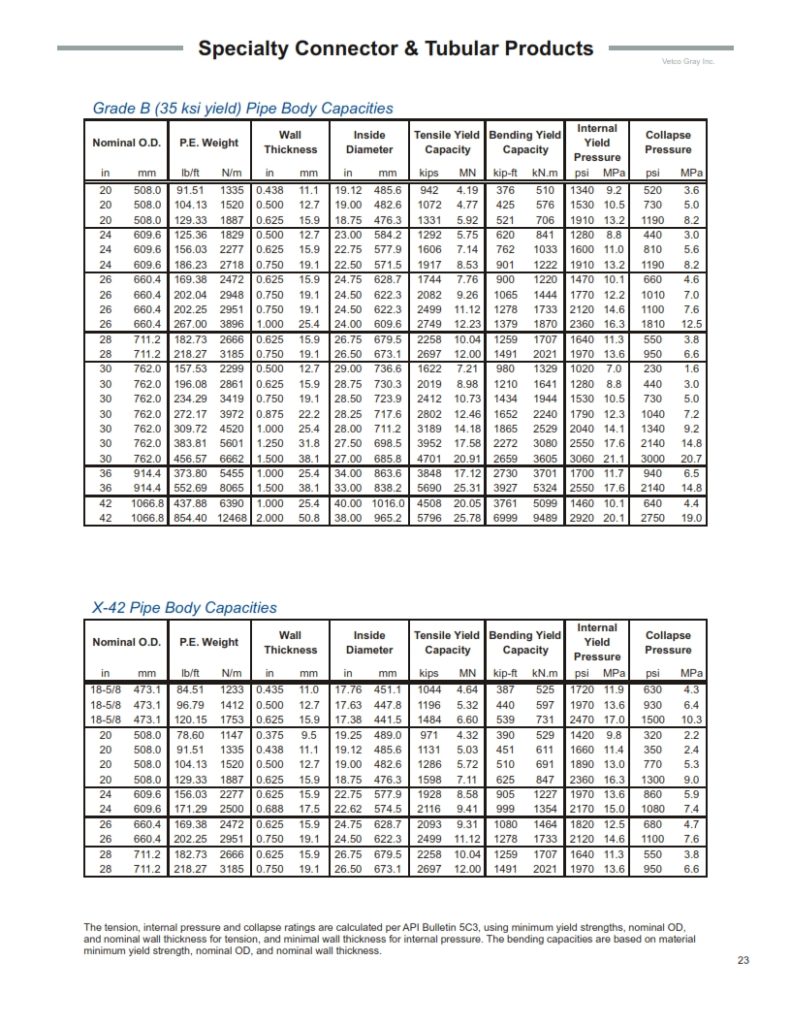

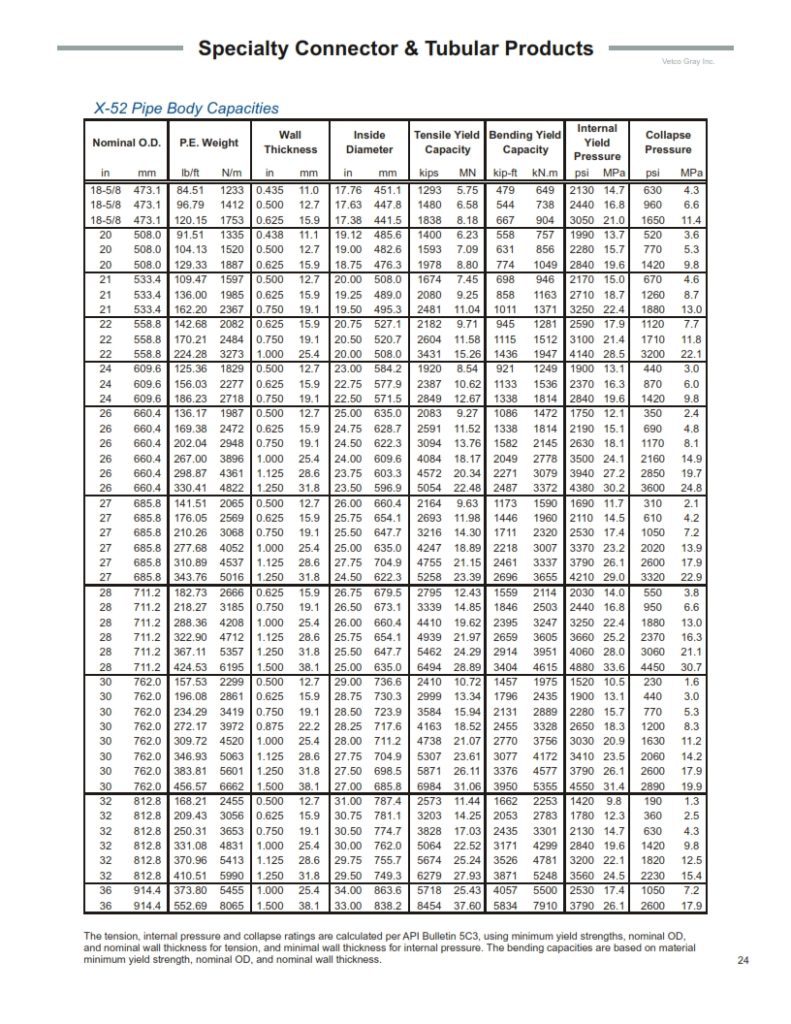

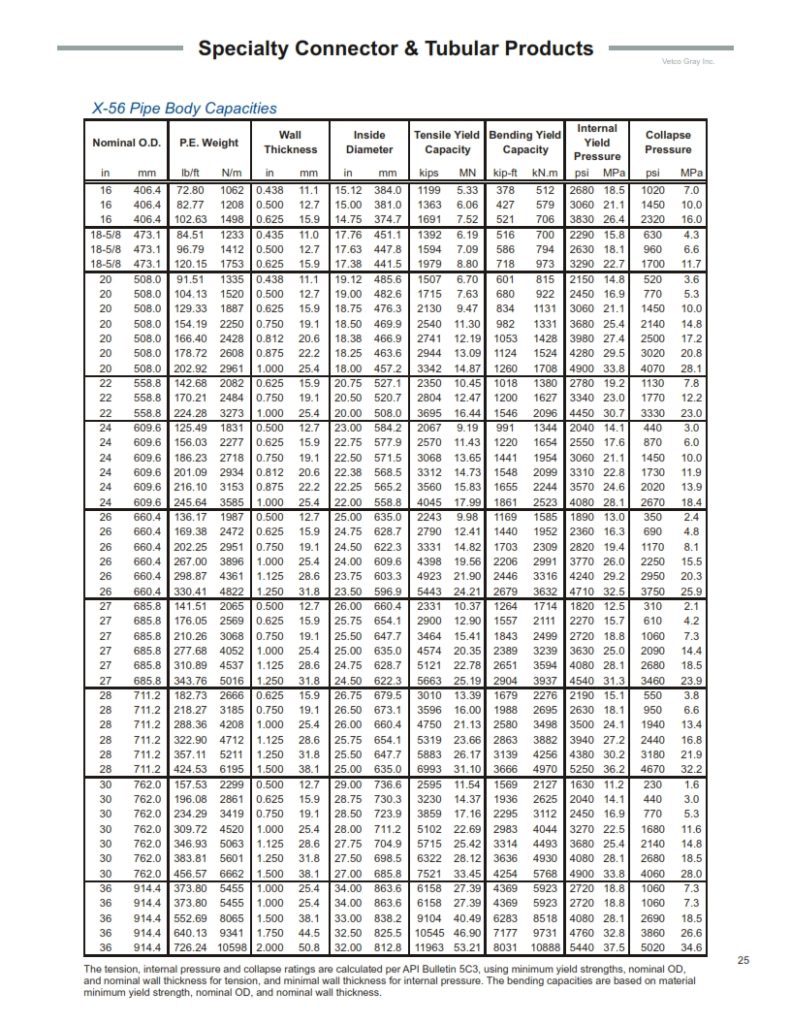

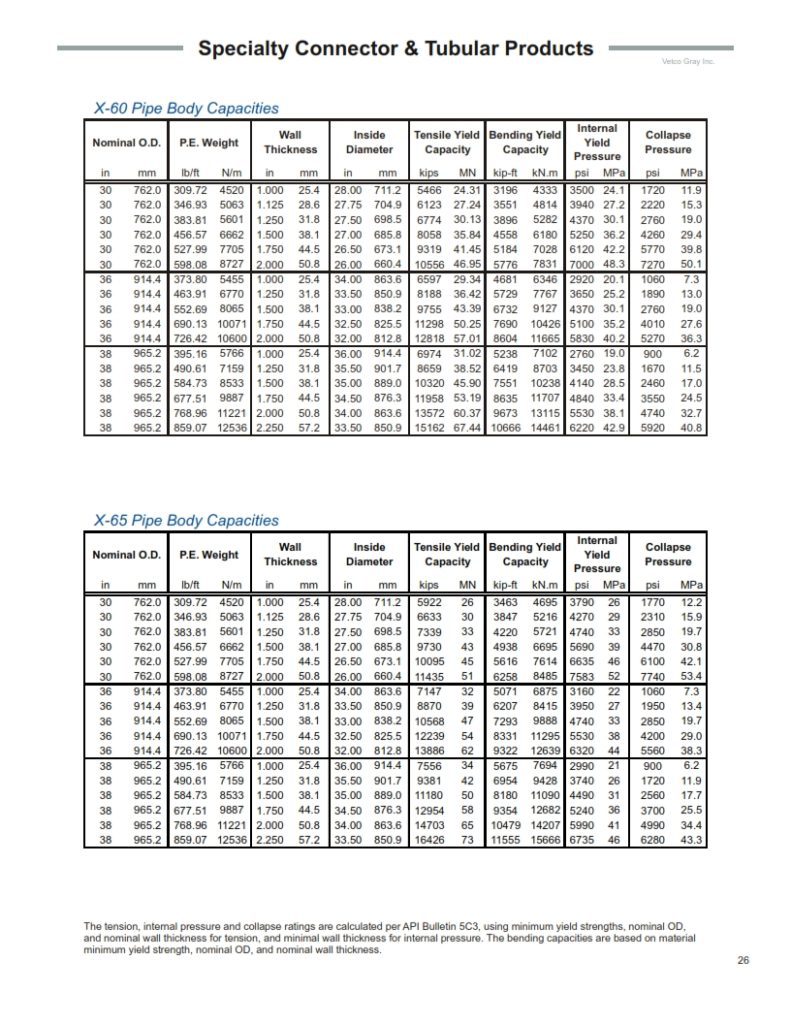

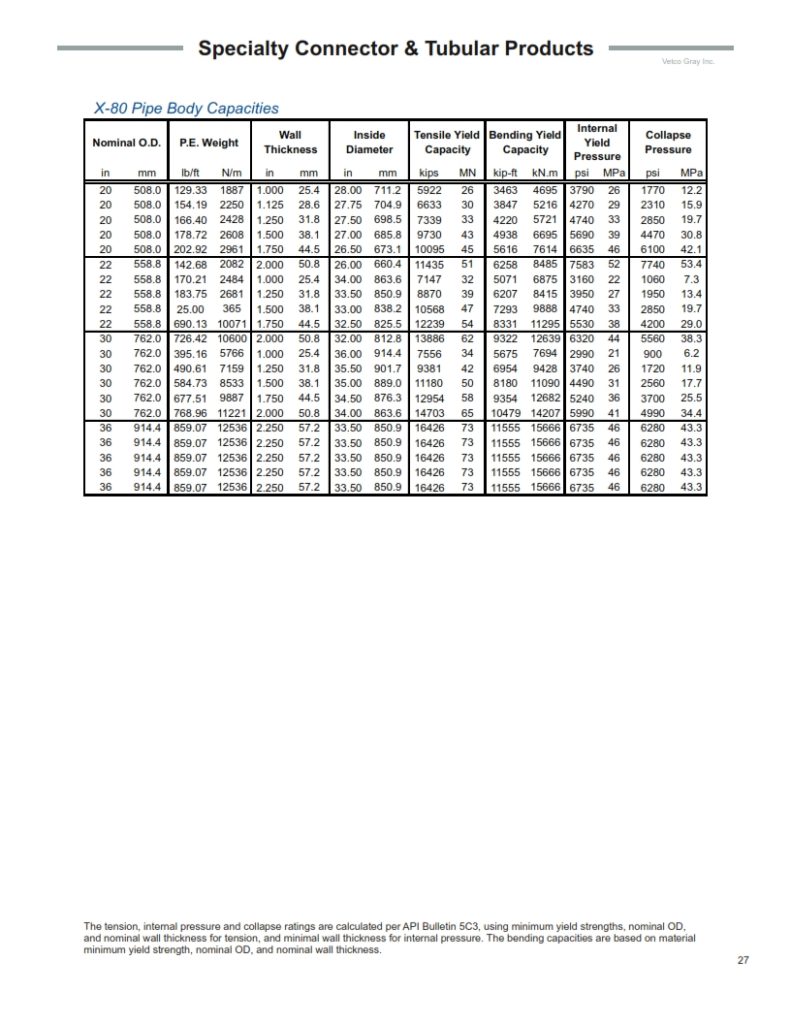

Below, we have gathered some of the conductor casing pipe specs tables from oil and gas NOV & Varcogray.

XL Systems–National Oilwell Varco—XLC-S

Type: Integral, flush Seal: Metal-to-metal

| OD | Weight | ID (drift), in. | wall thickness | Connection OD, in. | Casing wall critical cross-sectional | Connection critical cross-sectional | Tensile efficiency, % | Compression efficiency, % | L-80 Joint strength, kips | L-80 Yield torque ft-lb | P-110 Joint strength kips | P-110 Yield torque ft-lb | Q-125 Joint strength kips | Q-125 Yield torque ft-lb |

| 26 | 202.3 | 24.5 | 0.75 | 26 | 59.494 | 39.427 | 66 | 66 | 3,154 | 233,000 | 4,337 | 320,000 | 4,928 | 364,000 |

| 26 | 267 | 24 | 1 | 26 | 78.54 | 55.097 | 70 | 70 | 4,408 | 319,000 | 6,061 | 439,000 | 6,887 | 498,000 |

| 26 | 330.4 | 23.5 | 1.25 | 26 | 97.193 | 75.519 | 78 | 78 | 6,042 | 429,000 | 8,307 | 590,000 | 9,440 | 670,000 |

| 26 | 392.5 | 23 | 1.5 | 26 | 115.454 | 91.118 | 79 | 79 | 7,289 | 508,000 | 10,023 | 698,000 | 11,390 | 793,000 |

| 30 | 234.3 | 28.5 | 0.75 | 30 | 68.919 | 45.61 | 66 | 66 | 3,649 | 313,000 | 5,017 | 430,000 | 5,701 | 489,000 |

| 30 | 309.7 | 28 | 1 | 30 | 91.106 | 63.805 | 70 | 70 | 5,104 | 431,000 | 7,019 | 592,000 | 7,976 | 673,000 |

| 30 | 383.8 | 27.5 | 1.25 | 30 | 112.901 | 87.583 | 78 | 78 | 7,007 | 581,000 | 9,634 | 799,000 | 10,948 | 908,000 |

| 30 | 456.6 | 27 | 1.5 | 30 | 134.303 | 105.796 | 79 | 79 | 8,464 | 691,000 | 11,638 | 950,000 | 13,225 | 1,079,000 |

| 30 | 528 | 26.5 | 1.75 | 30 | 155.312 | 124.079 | 80 | 80 | 9,926 | 797,000 | 13,649 | 1,095,000 | 15,510 | 1,245,000 |

| 30 | 598.1 | 26 | 2 | 30 | 175.929 | 141.912 | 81 | 81 | 11,353 | 896,000 | 15,610 | 1,232,000 | 17,739 | 1,400,000 |

| 32 | 250.3 | 30.5 | 0.75 | 32 | 73.631 | 48.701 | 66 | 66 | 3,896 | 358,000 | 5,357 | 492,000 | 6,088 | 559,000 |

| 32 | 331.1 | 30 | 1 | 32 | 97.389 | 68.159 | 70 | 70 | 5,453 | 493,000 | 7,497 | 677,000 | 8,520 | 770,000 |

| 32 | 410.5 | 29.5 | 1.25 | 32 | 120.755 | 93.615 | 78 | 78 | 7,489 | 666,000 | 10,298 | 916,000 | 11,702 | 1,041,000 |

| 32 | 488.6 | 29 | 1.5 | 32 | 143.728 | 113.135 | 79 | 79 | 9,051 | 793,000 | 12,445 | 1,090,000 | 14,142 | 1,238,000 |

| 32 | 565.4 | 28.5 | 1.75 | 32 | 166.308 | 132.75 | 80 | 80 | 10,620 | 916,000 | 14,603 | 1,259,000 | 16,594 | 1,431,000 |

| 32 | 640.8 | 28 | 2 | 32 | 188.496 | 151.902 | 81 | 81 | 12,152 | 1,032,000 | 16,709 | 1,419,000 | 18,988 | 1,612,000 |

| 34 | 266.3 | 32.5 | 0.75 | 34 | 78.343 | 51.792 | 66 | 66 | 4,143 | 405,000 | 5,697 | 557,000 | 6,474 | 633,000 |

| 34 | 352.4 | 32 | 1 | 34 | 103.673 | 72.514 | 70 | 70 | 5,801 | 559,000 | 7,977 | 768,000 | 9,064 | 873,000 |

| 34 | 437.2 | 31.5 | 1.25 | 34 | 128.609 | 99.646 | 77 | 77 | 7,972 | 757,000 | 10,961 | 1,041,000 | 12,456 | 1,183,000 |

| 34 | 520.7 | 31 | 1.5 | 34 | 153.153 | 120.473 | 79 | 79 | 9,638 | 902,000 | 13,252 | 1,240,000 | 15,059 | 1,409,000 |

| 34 | 602.8 | 30.5 | 1.75 | 34 | 177.304 | 141.421 | 80 | 80 | 11,314 | 1,043,000 | 15,556 | 1,434,000 | 17,678 | 1,630,000 |

| 34 | 683.5 | 30 | 2 | 34 | 201.062 | 161.893 | 81 | 81 | 12,951 | 1,177,000 | 17,808 | 1,618,000 | 20,237 | 1,839,000 |

| 36 | 282.4 | 34.5 | 0.75 | 36 | 83.056 | 54.884 | 66 | 66 | 4,391 | 456,000 | 6,037 | 627,000 | 6,861 | 712,000 |

| 36 | 373.8 | 34 | 1 | 36 | 109.956 | 76.868 | 70 | 70 | 6,149 | 629,000 | 8,455 | 865,000 | 9,609 | 983,000 |

| 36 | 463.9 | 33.5 | 1.25 | 36 | 136.463 | 105.678 | 77 | 77 | 8,454 | 853,000 | 11,625 | 1,173,000 | 13,210 | 1,333,000 |

| 36 | 552.7 | 33 | 1.5 | 36 | 162.577 | 127.812 | 79 | 79 | 10,225 | 1,018,000 | 14,059 | 1,400,000 | 15,977 | 1,590,000 |

| 36 | 640.1 | 32.5 | 1.75 | 36 | 188.299 | 150.092 | 80 | 80 | 12,007 | 1,179,000 | 16,510 | 1,621,000 | 18,762 | 1,842,000 |

| 36 | 726.2 | 32 | 2 | 36 | 213.628 | 171.883 | 80 | 80 | 13,751 | 1,332,000 | 18,907 | 1,831,000 | 21,485 | 2,081,000 |

| 38 | 298.4 | 36.5 | 0.75 | 38 | 87.768 | 57.975 | 66 | 66 | 4,638 | 509,000 | 6,377 | 700,000 | 7,247 | 796,000 |

| 38 | 395.2 | 36 | 1 | 38 | 116.239 | 81.222 | 70 | 70 | 6,498 | 704,000 | 8,934 | 968,000 | 10,153 | 1,100,000 |

| 38 | 490.6 | 35.5 | 1.25 | 38 | 144.317 | 111.71 | 77 | 77 | 8,937 | 956,000 | 12,288 | 1,314,000 | 13,964 | 1,493,000 |

| 38 | 584.7 | 35 | 1.5 | 38 | 172.002 | 135.151 | 79 | 79 | 10,812 | 1,141,000 | 14,867 | 1,569,000 | 16,894 | 1,783,000 |

| 38 | 677.5 | 34.5 | 1.75 | 38 | 199.295 | 158.763 | 80 | 80 | 12,701 | 1,323,000 | 17,464 | 1,819,000 | 19,845 | 2,067,000 |

| 38 | 769 | 34 | 2 | 38 | 226.195 | 181.873 | 80 | 80 | 14,550 | 1,496,000 | 20,006 | 2,057,000 | 22,734 | 2,337,000 |

| 40 | 314.4 | 38.5 | 0.75 | 40 | 92.481 | 61.066 | 66 | 66 | 4,885 | 566,000 | 6,717 | 778,000 | 7,633 | 884,000 |

| 40 | 416.5 | 38 | 1 | 40 | 122.522 | 85.576 | 70 | 70 | 6,846 | 783,000 | 9,413 | 1,076,000 | 10,697 | 1,223,000 |

| 40 | 517.3 | 37.5 | 1.25 | 40 | 152.171 | 117.742 | 77 | 77 | 9,419 | 1,064,000 | 12,952 | 1,463,000 | 14,718 | 1,662,000 |

| 40 | 616.8 | 37 | 1.5 | 40 | 181.427 | 142.49 | 79 | 79 | 11,399 | 1,271,000 | 15,674 | 1,748,000 | 17,811 | 1,987,000 |

| 40 | 714.9 | 36.5 | 1.75 | 40 | 210.29 | 167.433 | 80 | 80 | 13,395 | 1,475,000 | 18,418 | 2,029,000 | 20,929 | 2,305,000 |

| 40 | 811.7 | 36 | 2 | 40 | 238.761 | 191.863 | 80 | 80 | 15,349 | 1,670,000 | 21,105 | 2,296,000 | 23,983 | 2,609,000 |

| 40 | 907.1 | 35.5 | 2.25 | 40 | 266.839 | 221.51 | 83 | 83 | 17,721 | 1,904,000 | 24,366 | 2,618,000 | 27,689 | 2,975,000 |

| 42 | 330.4 | 40.5 | 0.75 | 42 | 97.193 | 64.158 | 66 | 66 | 5,133 | 625,000 | 7,057 | 860,000 | 8,020 | 977,000 |

| 42 | 437.9 | 40 | 1 | 42 | 128.805 | 89.931 | 70 | 70 | 7,194 | 866,000 | 9,892 | 1,191,000 | 11,241 | 1,353,000 |

| 42 | 544 | 39.5 | 1.25 | 42 | 160.025 | 123.774 | 77 | 77 | 9,902 | 1,178,000 | 13,615 | 1,619,000 | 15,472 | 1,840,000 |

| 42 | 648.8 | 39 | 1.5 | 42 | 190.852 | 149.828 | 79 | 79 | 11,986 | 1,409,000 | 16,481 | 1,937,000 | 18,729 | 2,201,000 |

| 42 | 752.3 | 38.5 | 1.75 | 42 | 221.286 | 176.104 | 80 | 80 | 14,088 | 1,636,000 | 19,371 | 2,250,000 | 22,013 | 2,557,000 |

| 42 | 854.4 | 38 | 2 | 42 | 251.327 | 201.854 | 80 | 80 | 16,148 | 1,853,000 | 22,204 | 2,548,000 | 25,232 | 2,896,000 |

| 42 | 955.2 | 37.5 | 2.25 | 42 | 280.976 | 223.36 | 79 | 79 | 17,869 | 2,027,000 | 24,570 | 2,787,000 | 27,920 | 3,167,000 |

| 44 | 346.4 | 42.5 | 0.75 | 44 | 101.905 | 67.249 | 66 | 66 | 5,380 | 688,000 | 7,397 | 945,000 | 8,406 | 1,074,000 |

| 44 | 459.2 | 42 | 1 | 44 | 135.088 | 94.285 | 70 | 70 | 7,543 | 953,000 | 10,371 | 1,310,000 | 11,786 | 1,489,000 |

| 44 | 570.7 | 41.5 | 1.25 | 44 | 167.879 | 129.806 | 77 | 77 | 10,384 | 1,297,000 | 14,279 | 1,784,000 | 16,226 | 2,027,000 |

| 44 | 680.9 | 41 | 1.5 | 44 | 200.277 | 157.167 | 78 | 78 | 12,573 | 1,553,000 | 17,288 | 2,135,000 | 19,646 | 2,427,000 |

| 44 | 789.7 | 40.5 | 1.75 | 44 | 232.282 | 184.775 | 80 | 80 | 14,782 | 1,805,000 | 20,325 | 2,482,000 | 23,097 | 2,821,000 |

| 44 | 897.1 | 40 | 2 | 44 | 263.894 | 211.844 | 80 | 80 | 16,948 | 2,046,000 | 23,303 | 2,814,000 | 26,481 | 3,198,000 |

| 44 | 1003.3 | 39.5 | 2.25 | 44 | 295.113 | 245.21 | 83 | 83 | 19,617 | 2,342,000 | 26,973 | 3,221,000 | 30,651 | 3,660,000 |

| 46 | 362.5 | 44.5 | 0.75 | 46 | 106.618 | 70.34 | 66 | 66 | 5,627 | 753,000 | 7,737 | 1,035,000 | 8,793 | 1,176,000 |

| 46 | 480.6 | 44 | 1 | 46 | 141.372 | 98.639 | 70 | 70 | 7,891 | 1,044,000 | 10,850 | 1,436,000 | 12,330 | 1,632,000 |

| 46 | 597.4 | 43.5 | 1.25 | 46 | 175.733 | 135.838 | 77 | 77 | 10,867 | 1,423,000 | 14,942 | 1,956,000 | 16,980 | 2,223,000 |

| 46 | 712.9 | 43 | 1.5 | 46 | 209.701 | 164.506 | 78 | 78 | 13,160 | 1,705,000 | 18,096 | 2,344,000 | 20,563 | 2,663,000 |

| 46 | 827 | 42.5 | 1.75 | 46 | 243.277 | 193.446 | 80 | 80 | 15,476 | 1,983,000 | 21,279 | 2,726,000 | 24,181 | 3,098,000 |

| 46 | 939.8 | 42 | 2 | 46 | 276.46 | 221.834 | 80 | 80 | 17,747 | 2,249,000 | 24,402 | 3,093,000 | 27,729 | 3,514,000 |

| 46 | 1051.3 | 41.5 | 2.25 | 46 | 309.251 | 257.13 | 83 | 83 | 20,570 | 2,579,000 | 28,284 | 3,546,000 | 32,141 | 4,030,000 |

| 46 | 1161.5 | 41 | 2.5 | 46 | 341.648 | 291.593 | 85 | 85 | 23,327 | 2,893,000 | 32,075 | 3,978,000 | 36,449 | 4,521,000 |

| 48 | 378.5 | 46.5 | 0.75 | 48 | 111.33 | 73.432 | 66 | 66 | 5,875 | 821,000 | 8,078 | 1,129,000 | 9,179 | 1,283,000 |

| 48 | 502 | 46 | 1 | 48 | 147.655 | 102.994 | 70 | 70 | 8,240 | 1,140,000 | 11,329 | 1,568,000 | 12,874 | 1,781,000 |

| 48 | 624.1 | 45.5 | 1.25 | 48 | 183.587 | 141.87 | 77 | 77 | 11,350 | 1,554,000 | 15,606 | 2,137,000 | 17,734 | 2,428,000 |

| 48 | 744.9 | 45 | 1.5 | 48 | 219.126 | 171.845 | 78 | 78 | 13,748 | 1,863,000 | 18,903 | 2,562,000 | 21,481 | 2,911,000 |

| 48 | 864.4 | 44.5 | 1.75 | 48 | 254.273 | 202.117 | 79 | 79 | 16,169 | 2,169,000 | 22,233 | 2,982,000 | 25,265 | 3,388,000 |

| 48 | 982.6 | 44 | 2 | 48 | 289.027 | 231.825 | 80 | 80 | 18,546 | 2,462,000 | 25,501 | 3,385,000 | 28,978 | 3,846,000 |

| 48 | 1099.4 | 43.5 | 2.25 | 48 | 323.388 | 268.779 | 83 | 83 | 21,502 | 2,825,000 | 29,566 | 3,884,000 | 33,597 | 4,413,000 |

XL Systems–National Oilwell Varco—XLF

Type: Integral, flush Seal: Metal-to-metal

| OD | Weight | ID (drift), in. | wall thickness | Connection OD, in. | Casing wall critical cross-sectional | Connection critical cross-sectional | Tensile efficiency, % | Compression efficiency, % | L-80 Joint strength, kips | L-80 Yield torque ft-lb | P-110 Joint strength kips | P-110 Yield torque ft-lb | Q-125 Joint strength kips | Q-125 Yield torque ft-lb+O78:O101O78:O1O78:O105 |

| 20 | 104.1 | 19 | 0.5 | 20 | 30.631 | 15.879 | 52 | 52 | 1,270 | 73,000 | 1,747 | 100,000 | 1,985 | 113,000 |

| 20 | 129.3 | 18.75 | 0.625 | 20 | 38.043 | 20.082 | 53 | 53 | 1,607 | 91,000 | 2,209 | 125,000 | 2,510 | 142,000 |

| 20 | 131.3 | 18.73 | 0.635 | 20 | 38.631 | 20.082 | 52 | 52 | 1,607 | 91,000 | 2,209 | 125,000 | 2,510 | 142,000 |

| 20 | 154.2 | 18.5 | 0.75 | 20 | 45.357 | 25.076 | 55 | 55 | 2,006 | 112,000 | 2,758 | 154,000 | 3,135 | 175,000 |

| 20 | 166.4 | 18.376 | 0.812 | 20 | 48.948 | 25.076 | 51 | 51 | 2,006 | 111,000 | 2,758 | 153,000 | 3,135 | 174,000 |

| 20 | 202.9 | 18 | 1 | 20 | 59.69 | 38.455 | 64 | 64 | 3,076 | 167,000 | 4,230 | 230,000 | 4,807 | 261,000 |

| 20 | 250.3 | 17.5 | 1.25 | 20 | 73.631 | 50.994 | 69 | 69 | 4,080 | 216,000 | 5,609 | 298,000 | 6,374 | 338,000 |

| 22 | 114.8 | 21 | 0.5 | 22 | 33.772 | 17.488 | 52 | 52 | 1,399 | 88,000 | 1,924 | 122,000 | 2,186 | 138,000 |

| 22 | 142.7 | 20.75 | 0.625 | 22 | 41.97 | 22.124 | 53 | 53 | 1,770 | 111,000 | 2,434 | 152,000 | 2,766 | 173,000 |

| 22 | 170.2 | 20.5 | 0.75 | 22 | 50.069 | 27.636 | 55 | 55 | 2,211 | 137,000 | 3,040 | 188,000 | 3,455 | 213,000 |

| 22 | 224.3 | 20 | 1 | 22 | 65.973 | 42.426 | 64 | 64 | 3,394 | 205,000 | 4,667 | 282,000 | 5,303 | 320,000 |

| 22 | 277 | 19.5 | 1.25 | 22 | 81.485 | 56.319 | 69 | 69 | 4,506 | 266,000 | 6,195 | 366,000 | 7,040 | 416,000 |

| 24 | 125.5 | 23 | 0.5 | 24 | 36.914 | 19.096 | 52 | 52 | 1,528 | 106,000 | 2,101 | 145,000 | 2,387 | 165,000 |

| 24 | 156 | 22.75 | 0.625 | 24 | 45.897 | 24.165 | 53 | 53 | 1,933 | 132,000 | 2,658 | 182,000 | 3,021 | 207,000 |

| 24 | 186.2 | 22.5 | 0.75 | 24 | 54.782 | 30.196 | 55 | 55 | 2,416 | 164,000 | 3,322 | 225,000 | 3,775 | 256,000 |

| 24 | 245.6 | 22 | 1 | 24 | 72.257 | 46.397 | 64 | 64 | 3,712 | 246,000 | 5,104 | 339,000 | 5,800 | 385,000 |

| 24 | 303.7 | 21.5 | 1.25 | 24 | 89.339 | 61.644 | 69 | 69 | 4,932 | 321,000 | 6,781 | 441,000 | 7,706 | 501,000 |

| 24 | 360.5 | 21 | 1.5 | 24 | 106.029 | 70.174 | 66 | 66 | 5,614 | 357,000 | 7,719 | 491,000 | 8,772 | 559,000 |

| 26 | 136.2 | 25 | 0.5 | 26 | 40.055 | 20.705 | 52 | 52 | 1,656 | 125,000 | 2,278 | 171,000 | 2,588 | 195,000 |

| 26 | 169.4 | 24.75 | 0.625 | 26 | 49.824 | 26.207 | 53 | 53 | 2,097 | 156,000 | 2,883 | 215,000 | 3,276 | 244,000 |

| 26 | 202.3 | 24.5 | 0.75 | 26 | 59.494 | 32.756 | 55 | 55 | 2,620 | 193,000 | 3,603 | 266,000 | 4,095 | 302,000 |

| 26 | 267 | 24 | 1 | 26 | 78.54 | 50.368 | 64 | 64 | 4,029 | 292,000 | 5,540 | 401,000 | 6,296 | 456,000 |

| 26 | 330.4 | 23.5 | 1.25 | 26 | 97.193 | 66.969 | 69 | 69 | 5,358 | 380,000 | 7,367 | 523,000 | 8,371 | 594,000 |

| 26 | 392.5 | 23 | 1.5 | 26 | 115.454 | 76.268 | 66 | 66 | 6,101 | 425,000 | 8,389 | 584,000 | 9,534 | 664,000 |

| 28 | 146.9 | 27 | 0.5 | 28 | 43.197 | 22.313 | 52 | 52 | 1,785 | 145,000 | 2,454 | 199,000 | 2,789 | 226,000 |

| 28 | 182.7 | 26.75 | 0.625 | 28 | 53.751 | 28.248 | 53 | 53 | 2,260 | 182,000 | 3,107 | 250,000 | 3,531 | 284,000 |

| 28 | 218.3 | 26.5 | 0.75 | 28 | 64.206 | 35.315 | 55 | 55 | 2,825 | 225,000 | 3,885 | 310,000 | 4,414 | 352,000 |

| 28 | 288.4 | 26 | 1 | 28 | 84.823 | 54.339 | 64 | 64 | 4,347 | 341,000 | 5,977 | 468,000 | 6,792 | 532,000 |

| 28 | 357.1 | 25.5 | 1.25 | 28 | 105.047 | 72.294 | 69 | 69 | 5,784 | 445,000 | 7,952 | 612,000 | 9,037 | 696,000 |

| 28 | 424.5 | 25 | 1.5 | 28 | 124.878 | 82.362 | 66 | 66 | 6,589 | 498,000 | 9,060 | 685,000 | 10,295 | 778,000 |

| 30 | 196.1 | 28.75 | 0.625 | 30 | 57.678 | 30.29 | 53 | 53 | 2,423 | 210,000 | 3,332 | 288,000 | 3,786 | 327,000 |

| 30 | 234.3 | 28.5 | 0.75 | 30 | 68.919 | 37.875 | 55 | 55 | 3,030 | 260,000 | 4,166 | 357,000 | 4,734 | 406,000 |

| 30 | 309.7 | 28 | 1 | 30 | 91.106 | 58.31 | 64 | 64 | 4,665 | 393,000 | 6,414 | 541,000 | 7,289 | 615,000 |

| 30 | 383.8 | 27.5 | 1.25 | 30 | 112.901 | 77.619 | 69 | 69 | 6,210 | 515,000 | 8,538 | 708,000 | 9,702 | 805,000 |

| 30 | 456.6 | 27 | 1.5 | 30 | 134.303 | 88.456 | 66 | 66 | 7,076 | 577,000 | 9,730 | 794,000 | 11,057 | 902,000 |

| 30 | 528 | 26.5 | 1.75 | 30 | 155.312 | 110.584 | 71 | 71 | 8,847 | 710,000 | 12,164 | 976,000 | 13,823 | 1,109,000 |

| 30 | 598.1 | 26 | 2 | 30 | 175.929 | 130.267 | 74 | 74 | 10421 | 832000 | 14329 | 1131000 | 16283 | 1285000 |

XL Systems–National Oilwell Varco—Viper

Type: Weld-on pin and box Seal: Internal elastomeric and external metal-to-metal

| OD | Weight | ID (drift), in. | wall thickness | Connection OD, in. | Casing wall critical cross-sectional | Connection critical cross-sectional | Tensile efficiency, % | Compression efficiency, % | L-80 Joint strength, kips | L-80 Yield torque ft-lb | P-110 Joint strength kips | P-110 Yield torque ft-lb | Q-125 Joint strength kips | Q-125 Yield torque ft-lb |

| 16 | 72.9 | 14.624 | 0.438 | 17.5 | 21.414 | 31.038 | 144.9 | 99.8 | 2,483 | 171,451 | – | – | – | – |

| 16 | 77.7 | 14.564 | 0.468 | 17.5 | 22.836 | 31.038 | 135.9 | 93.6 | 2,483 | 171,451 | – | – | – | – |

| 16 | 82.8 | 14.5 | 0.5 | 17.5 | 24.347 | 31.038 | 127.5 | 87.8 | 2,483 | 171,451 | – | – | – | – |

| 16 | 102.7 | 14.25 | 0.625 | 17.5 | 30.189 | 39.675 | 131.4 | 98.9 | 3,174 | 232,802 | – | – | – | – |

| 16 | 112.6 | 14.124 | 0.688 | 17.5 | 33.096 | 45.25 | 136.7 | 93.7 | 3,620 | 234,007 | – | – | – | – |

| 16 | 122.3 | 14 | 0.75 | 17.5 | 35.932 | 45.25 | 125.9 | 86.3 | 3,620 | 234,007 | – | – | – | – |

| 18.625 | 85.2 | 17.249 | 0.438 | 20.35 | 25.026 | 36.15 | 144.5 | 95.1 | 2,892 | 223,035 | – | – | – | – |

| 18.625 | 90.8 | 17.189 | 0.468 | 20.35 | 26.696 | 36.15 | 135.4 | 89.2 | 2,892 | 223,035 | – | – | – | – |

| 18.625 | 96.9 | 17.125 | 0.5 | 20.35 | 28.471 | 36.15 | 127 | 83.6 | 2,892 | 223,035 | – | – | – | – |

| 18.625 | 120.3 | 16.875 | 0.625 | 20.35 | 35.343 | 45.938 | 130 | 82.3 | 3,675 | 271,069 | – | – | – | – |

| 18.625 | 131.9 | 16.749 | 0.688 | 20.35 | 38.769 | 53.625 | 138.3 | 91.5 | 4,290 | 310,389 | – | – | – | – |

| 18.625 | 143.3 | 16.625 | 0.75 | 20.35 | 42.117 | 53.625 | 127.3 | 84.2 | 4,290 | 310,389 | – | – | – | – |

| 20 | 91.6 | 18.53 | 0.438 | 21.62 | 26.918 | 49.825 | 185.1 | 120.9 | 3,986 | 306,595 | – | – | – | – |

| 20 | 104.2 | 18.5 | 0.5 | 21.62 | 30.631 | 49.825 | 162.7 | 106.3 | 3,986 | 306,595 | – | – | – | – |

| 20 | 129.4 | 18.25 | 0.625 | 21.62 | 38.043 | 49.825 | 131 | 85.6 | 3,986 | 306,595 | – | – | – | – |

| 20 | 154.3 | 18 | 0.75 | 21.62 | 45.357 | 63.925 | 140.9 | 91.2 | 5,114 | 386,308 | – | – | – | – |

| 20 | 166.6 | 17.876 | 0.812 | 21.62 | 48.948 | 63.925 | 130.6 | 84.5 | 5,114 | 386,308 | – | – | – | – |

| 20 | 203.1 | 17.5 | 1 | 21.62 | 59.69 | 54.125 | 90.7 | 59.3 | 4,330 | 452,924 | – | – | – | – |

| 20 | 227 | 16.9 | 1.125 | 21.62 | 66.71 | 80.888 | 121.3 | 105.4 | 6,471 | 575,810 | – | – | – | – |

| 20 | 250.5 | 16.9 | 1.25 | 21.62 | 73.631 | 80.888 | 109.9 | 95.5 | 6,471 | 575,810 | – | – | – | – |

| 20 | 296.6 | 16.5 | 1.5 | 21.62 | 87.179 | 80.888 | 92.8 | 80.6 | 6,471 | 575,810 | – | – | – | – |

| 22 | 101 | 20.53 | 0.438 | 23.8 | 29.67 | 55.638 | 187.5 | 145.9 | 4,451 | 479,151 | – | – | – | – |

| 22 | 114.9 | 20.5 | 0.5 | 23.8 | 33.772 | 55.638 | 164.7 | 128.2 | 4,451 | 479,151 | – | – | – | – |

| 22 | 142.8 | 20.25 | 0.625 | 23.8 | 41.97 | 55.638 | 132.6 | 103.2 | 4,451 | 479,151 | – | – | – | – |

| 22 | 170.4 | 20 | 0.75 | 23.8 | 50.069 | 67.225 | 134.3 | 106.6 | 5,378 | 576,414 | – | – | – | – |

| 22 | 183.9 | 19.876 | 0.812 | 23.8 | 54.05 | 67.225 | 124.4 | 98.7 | 5,378 | 576,414 | – | – | – | – |

| 22 | 224.5 | 19.5 | 1 | 23.8 | 65.973 | 76.925 | 116.6 | 96.8 | 6,154 | 658,016 | – | – | – | – |

| 22 | 251 | 18.9 | 1.125 | 23.8 | 73.778 | 86.663 | 117.5 | 115.4 | 6,933 | 809,562 | – | – | – | – |

| 22 | 277.3 | 18.9 | 1.25 | 23.8 | 81.485 | 86.663 | 106.4 | 104.5 | 6,933 | 809,562 | – | – | – | – |

| 22 | 328.7 | 18.5 | 1.5 | 23.8 | 96.604 | 86.663 | 89.7 | 88.1 | 6,933 | 809,562 | – | – | – | – |

| 24 | 125.6 | 22.15 | 0.5 | 25.8 | 36.914 | 68.513 | 185.6 | 168.6 | 5,481 | 732,375 | – | – | – | – |

| 24 | 156.2 | 22.15 | 0.625 | 25.8 | 45.897 | 68.513 | 149.3 | 135.6 | 5,481 | 732,375 | – | – | – | – |

| 24 | 186.4 | 22 | 0.75 | 25.8 | 54.782 | 68.513 | 125.1 | 113.6 | 5,481 | 732,375 | – | – | – | – |

| 24 | 201.3 | 21.876 | 0.812 | 25.8 | 59.152 | 82.913 | 140.2 | 116.9 | 6,633 | 789,503 | – | – | – | – |

| 24 | 245.9 | 21.5 | 1 | 25.8 | 72.257 | 82.913 | 114.7 | 95.7 | 6,633 | 789,503 | – | – | – | – |

| 24 | 275.1 | 20.9 | 1.125 | 25.8 | 80.847 | 93.938 | 116.2 | 114.2 | 7,515 | 975,484 | – | – | – | – |

| 24 | 304 | 20.9 | 1.25 | 25.8 | 89.339 | 93.938 | 105.1 | 103.4 | 7,515 | 975,484 | – | – | – | – |

| 24 | 360.8 | 20.5 | 1.5 | 25.8 | 106.029 | 93.938 | 88.6 | 87.1 | 7,515 | 975,484 | – | – | – | – |

| 26 | 136.3 | 24.15 | 0.5 | 27.8 | 40.055 | 73.738 | 184.1 | 168.5 | 5,899 | 864,301 | – | – | – | – |

| 26 | 169.5 | 24.15 | 0.625 | 27.8 | 49.824 | 73.738 | 148 | 135.5 | 5,899 | 864,301 | – | – | – | – |

| 26 | 202.4 | 24 | 0.75 | 27.8 | 59.494 | 73.738 | 123.9 | 113.5 | 5,899 | 864,301 | – | – | – | – |

| 26 | 218.6 | 23.876 | 0.812 | 27.8 | 64.254 | 90.188 | 140.4 | 116.3 | 7,215 | 932,958 | – | – | – | – |

| 26 | 267.3 | 23.5 | 1 | 27.8 | 78.54 | 90.188 | 114.8 | 95.2 | 7,215 | 932,958 | – | – | – | – |

| 26 | 299.2 | 22.9 | 1.125 | 27.8 | 87.916 | 101.838 | 115.8 | 113 | 8,147 | 1,156,863 | – | – | – | – |

| 26 | 330.7 | 22.9 | 1.25 | 27.8 | 97.193 | 101.838 | 104.8 | 102.2 | 8,147 | 1,156,863 | – | – | – | – |

| 26 | 392.9 | 22.5 | 1.5 | 27.8 | 115.454 | 101.838 | 88.2 | 86.1 | 8,147 | 1,156,863 | – | – | – | – |

| 28 | 147 | 26.15 | 0.5 | 29.8 | 43.197 | 79.975 | 185.1 | 164.4 | 6,398 | 1,007,147 | – | – | – | – |

| 28 | 182.9 | 26.15 | 0.625 | 29.8 | 53.751 | 79.975 | 148.8 | 132.1 | 6,398 | 1,007,147 | – | – | – | – |

| 28 | 218.5 | 26 | 0.75 | 29.8 | 64.206 | 79.975 | 124.6 | 110.6 | 6,398 | 1,007,147 | – | – | – | – |

| 28 | 236 | 25.876 | 0.812 | 29.8 | 69.356 | 96.638 | 139.3 | 114.8 | 7,731 | 1,088,382 | – | – | – | – |

| 28 | 288.6 | 25.5 | 1 | 29.8 | 84.823 | 96.638 | 113.9 | 93.9 | 7,731 | 1,088,382 | – | – | – | – |

| 28 | 323.2 | 24.9 | 1.125 | 29.8 | 94.984 | 109.538 | 115.3 | 112.8 | 8,763 | 1,353,703 | – | – | – | – |

| 28 | 357.4 | 24.9 | 1.25 | 29.8 | 105.047 | 109.538 | 104.3 | 102 | 8,763 | 1,353,703 | – | – | – | – |

| 28 | 424.9 | 24.5 | 1.5 | 29.8 | 124.878 | 109.538 | 87.7 | 85.8 | 8,763 | 1,353,703 | – | – | – | – |

| 30 | 157.7 | 27.65 | 0.5 | 32 | 46.338 | 106.988 | 230.9 | 235.8 | 8,559 | 1,601,052 | – | – | – | – |

| 30 | 196.3 | 27.65 | 0.625 | 32 | 57.678 | 106.988 | 185.5 | 189.4 | 8,559 | 1,601,052 | – | – | – | – |

| 30 | 234.5 | 27.65 | 0.75 | 32 | 68.919 | 106.988 | 155.2 | 158.5 | 8,559 | 1,601,052 | – | – | – | – |

| 30 | 310 | 27.5 | 1 | 32 | 91.106 | 106.988 | 117.4 | 119.9 | 8,559 | 1,601,052 | – | – | – | – |

| 30 | 347.3 | 26.78 | 1.125 | 32 | 102.053 | 133.125 | 130.4 | 137.9 | 10,650 | 1,889,490 | – | – | – | – |

| 30 | 384.2 | 26.78 | 1.25 | 32 | 112.901 | 133.125 | 117.9 | 124.6 | 10,650 | 1,889,490 | – | – | – | – |

| 30 | 457 | 26.5 | 1.5 | 32 | 134.303 | 133.125 | 99.1 | 104.8 | 10,650 | 1,889,490 | – | – | – | – |

| 30 | 528.5 | 25.9 | 1.75 | 32 | 155.312 | 150.663 | 97 | 110.8 | 12,053 | 2,165,271 | – | – | – | – |

| 30 | 598.6 | 25.5 | 2 | 32 | 175.929 | 150.663 | 85.6 | 97.8 | 12,053 | 2,165,271 | – | – | – | – |

| 32 | 168.4 | 29.65 | 0.5 | 34 | 49.48 | 113.913 | 230.2 | 231.6 | 9,113 | 1,829,649 | – | – | – | – |

| 32 | 209.6 | 29.65 | 0.625 | 34 | 61.605 | 113.913 | 184.9 | 186 | 9,113 | 1,829,649 | – | – | – | – |

| 32 | 250.5 | 29.65 | 0.75 | 34 | 73.631 | 113.913 | 154.7 | 155.7 | 9,113 | 1,829,649 | – | – | – | – |

| 32 | 331.4 | 29.5 | 1 | 34 | 97.389 | 113.913 | 117 | 117.7 | 9,113 | 1,829,649 | – | – | – | – |

| 32 | 371.3 | 28.78 | 1.125 | 34 | 109.121 | 142.35 | 130.5 | 134.4 | 11,388 | 2,163,167 | – | – | – | – |

| 32 | 410.9 | 28.78 | 1.25 | 34 | 120.755 | 142.35 | 117.9 | 121.5 | 11,388 | 2,163,167 | – | – | – | – |

| 32 | 489.1 | 28.5 | 1.5 | 34 | 143.728 | 142.35 | 99 | 102 | 11,388 | 2,163,167 | – | – | – | – |

| 32 | 565.9 | 27.9 | 1.75 | 34 | 166.308 | 160.7 | 96.6 | 109.5 | 12,856 | 2,485,833 | – | – | – | – |

| 32 | 641.4 | 27.5 | 2 | 34 | 188.496 | 160.7 | 85.3 | 96.7 | 12,856 | 2,485,833 | – | – | – | – |

| 34 | 179.1 | 31.65 | 0.5 | 36 | 52.622 | 120.713 | 229.4 | 230.2 | 9,657 | 2,073,497 | – | – | – | – |

| 34 | 223 | 31.65 | 0.625 | 36 | 65.532 | 120.713 | 184.2 | 184.8 | 9,657 | 2,073,497 | – | – | – | – |

| 34 | 266.6 | 31.65 | 0.75 | 36 | 78.343 | 120.713 | 154.1 | 154.6 | 9,657 | 2,073,497 | – | – | – | – |

| 34 | 352.8 | 31.5 | 1 | 36 | 103.673 | 120.713 | 116.4 | 116.8 | 9,657 | 2,073,497 | – | – | – | – |

| 34 | 395.4 | 30.78 | 1.125 | 36 | 116.19 | 150.7 | 129.7 | 133.3 | 12,056 | 2,458,775 | – | – | – | – |

| 34 | 437.6 | 30.78 | 1.25 | 36 | 128.609 | 150.7 | 117.2 | 120.4 | 12,056 | 2,458,775 | – | – | – | – |

| 34 | 521.1 | 30.5 | 1.5 | 36 | 153.153 | 150.7 | 98.4 | 101.1 | 12,056 | 2,458,775 | – | – | – | – |

| 34 | 603.3 | 29.9 | 1.75 | 36 | 177.304 | 169.638 | 95.7 | 109.1 | 13,571 | 2,828,530 | – | – | – | – |

| 34 | 684.2 | 29.5 | 2 | 36 | 201.062 | 169.638 | 84.4 | 96.2 | 13,571 | 2,828,530 | – | – | – | – |

| 36 | 282.6 | 31.22 | 0.75 | 36.88 | 83.056 | 173.3 | 208.7 | 270.8 | 13,864 | 2,830,291 | – | – | – | – |

| 36 | 374.2 | 31.22 | 1 | 36.88 | 109.956 | 173.3 | 157.6 | 204.6 | 13,864 | 2,830,291 | – | – | – | – |

| 36 | 419.4 | 31.22 | 1.125 | 36.88 | 123.258 | 173.3 | 140.6 | 182.5 | 13,864 | 2,830,291 | – | – | – | – |

| 36 | 464.3 | 31.22 | 1.25 | 36.88 | 136.463 | 173.3 | 127 | 164.8 | 13,864 | 2,830,291 | – | – | – | – |

| 36 | 553.2 | 31.22 | 1.5 | 36.88 | 162.577 | 173.3 | 106.6 | 138.3 | 13,864 | 2,830,291 | – | – | – | – |

| 36 | 640.7 | 31.22 | 1.75 | 36.88 | 188.299 | 189.5 | 100.6 | 92.7 | 15,160 | 2,261,941 | – | – | – | – |

| 36 | 726.9 | 31.22 | 2 | 36.88 | 213.628 | 189.5 | 88.7 | 81.7 | 15,160 | 2,261,941 | – | – | – | – |

| 36 | 811.8 | 30.15 | 2.25 | 36.88 | 238.565 | 219.3 | 91.9 | 96.5 | 17,544 | 2,884,661 | – | – | – | – |

| 36 | 895.3 | 30.15 | 2.5 | 36.88 | 263.108 | 219.3 | 83.3 | 87.5 | 17,544 | 2,884,661 | – | – | – | – |

| 38 | 298.7 | 33.22 | 0.75 | 38.88 | 87.768 | 182.75 | 208.2 | 272.7 | 14,620 | 3,189,264 | – | – | – | – |

| 38 | 395.5 | 33.22 | 1 | 38.88 | 116.239 | 182.75 | 157.2 | 205.9 | 14,620 | 3,189,264 | – | – | – | – |

| 38 | 443.5 | 33.22 | 1.125 | 38.88 | 130.327 | 182.75 | 140.2 | 183.7 | 14,620 | 3,189,264 | – | – | – | – |

| 38 | 491.1 | 33.22 | 1.25 | 38.88 | 144.317 | 182.75 | 126.6 | 165.9 | 14,620 | 3,189,264 | – | – | – | – |

| 38 | 585.3 | 33.22 | 1.5 | 38.88 | 172.002 | 182.75 | 106.2 | 139.2 | 14,620 | 3,189,264 | – | – | – | – |

| 38 | 678.1 | 33.22 | 1.75 | 38.88 | 199.295 | 201.638 | 101.2 | 91.7 | 16,131 | 2,548,581 | – | – | – | – |

| 38 | 769.7 | 33.22 | 2 | 38.88 | 226.195 | 201.638 | 89.1 | 80.8 | 16,131 | 2,548,581 | – | – | – | – |

| 38 | 859.9 | 32.15 | 2.25 | 38.88 | 252.702 | 231.113 | 91.5 | 96.3 | 18,489 | 3,257,936 | – | – | – | – |

| 38 | 948.7 | 32.15 | 2.5 | 38.88 | 278.816 | 231.113 | 82.9 | 87.3 | 18,489 | 3,257,936 | – | – | – | – |

Download Conductor Casing Pipe Tables

- Casing & Conductor Pipe Tables (Premium Connections)

- Vetcogray Connectors and conductor casing pipes specs

Conductor Casing Pipe Connections in Oil And Gas Wells

Typically, when installing conductor casing pipe joints on oil and gas land rigs (also see types of drilling rigs), the pipes are connected by welding beveled ends. This process can be time-consuming, taking an average of three hours per joint.

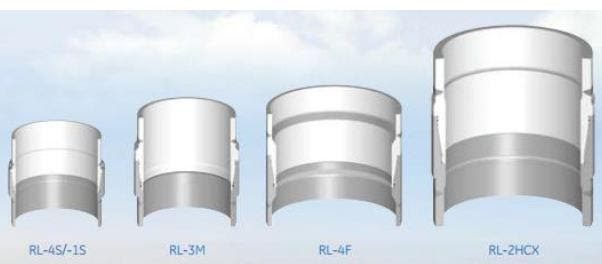

On a Jack-up rig, to reduce the time of the operations and when it is practicable, drivable threaded quick connectors (i.e., the RL-4) and drivable squinch joint connectors such as the Fast Releasing Joint (i.e., the ALT-2), should be used.

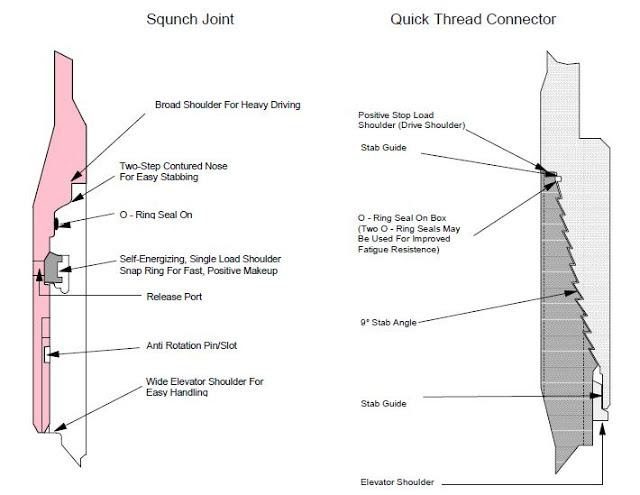

A Squnch Joint

- A Squnch Joint is a threadless automatic mechanical lock/release connection made up without rotation. The powerful weight-set connection is well-suited for connecting large-diameter conductor casing joints and connecting the string of casing to the wellhead housing extension.

- The type ALT-2 heavy-duty squinch joint is used for pipe joins. Generally, up to 36″ OD, but larger common conductor pipe sizes are available.

- It is easily stabbed, drivable, reusable, and can be released mechanically.

- It is suitable for the severest conditions above the mud line and can be used below it when the conductor is driven into place. The 20″ ALT-2 is an ideal high-pressure housing extension connector with an internal pressure rating of up to 5,000 psi.

- The type ST-2 standard duty squinch joint is not a drivable connector. It connects pipe joints up to 30″ OD, runs into a pre-drilled hole, and cements in place. It is recommended for use above the mud line and is reusable and mechanically released.

The Quick Thread Connection

The Quick Thread Connection RL-4 is rigid for conductor and casing connections and requires just one-quarter turn for full make-up.

The helix angle of the patented, interlocking thread form, in combination with other connector geometries, creates a preload force between the pin and box. The 30″ and larger RL-4 conductor casing connectors have a generous shoulder for efficient driving.

the anti-rotation tab

- Four identical threads 90° apart make up simultaneously. The thread interface is tapered at 4″ per ft of diameter. The connector box has four slots cut on the OD, close to the shoulder of the box, and the connector pin has four recessed grooves cut on its OD adjacent to the slots on the box.

- To activate the anti-rotation tab, a 90° incision is made with the impact tool into the anti-rotation slot. A metal strip is bent into the recessed groove in the pin, providing a positive mechanical lock.

It does not need power tongs for make-up and is releasable and reusable. It has a high 9° stab angle with dual stab guides. A negative 5° back rake thread interlock reduces belling tendency.

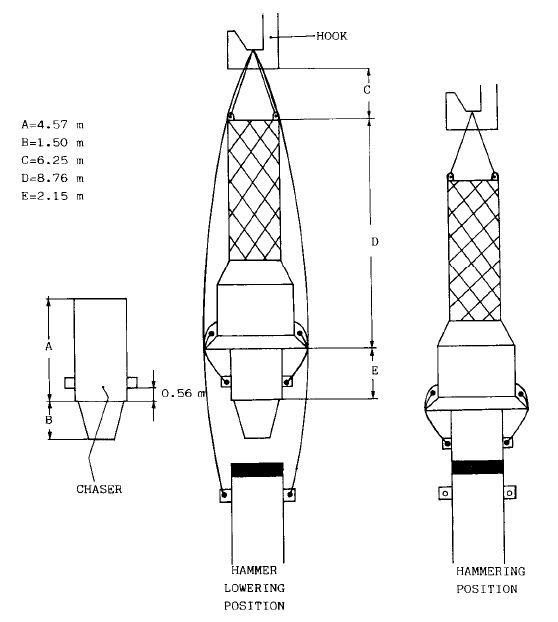

Conductor Casing Pipe Installation Hammers Types For Oil & Gas Wells

As mentioned before, a conductor casing pipe (CP) is necessary to provide a riser (drilling riser) and flow path for drilling mud from the well to the surface circulating system in Drilling. We should choose the OD and the wall thickness of the conductor pipe according to previous experiences in the area and to the selected casing profile.

Conductor casing Pipe installation can be done by driving with a pile hammer or pre-drilling a hole and cementing.

Conductor Casing Pipes Installation With Pile Hammers

Diesel pile hammers are used for surface installation and driving operations on conductor casing pipes in oil and gas wells. The driving depth of the conductor casing pipe is a function of the sediments in the ground.

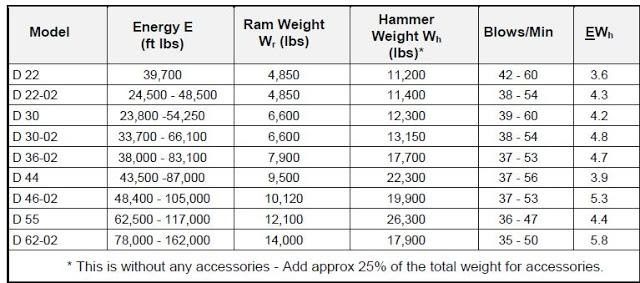

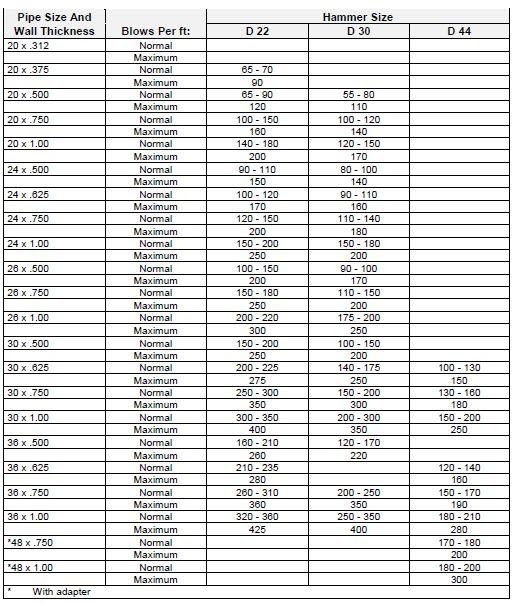

The most commonly used system is the ‘Delmag – D44 or D46′ which has a hammer weight of 18t with a variable delivery fuel pump. The table below shows the specifications of other types of Delmag Hammers. The Manufacturer’s Operating Procedures must be followed when planning driving operations.

The table below shows the standard and maximum blows/ft for different Conductor Casing Pipes and different conductor pipe hammer sizes for installation in oil and gas wells.

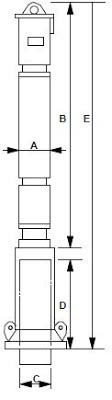

Conductor Casing Pipe Installation Hydro-Hammer

Frank’s Hydro-hammer is an ‘intelligent hammer’ due to its sophisticated electronic control design. This control system is capable of regulating the energy for each impact.

The net energy applied to the conductor pipe during installation, measured during every blow, is monitored and can be regulated from a maximum of 5% or less. Since the measure of energy is precisely known, the force applied to the pile can be accurately computed.

One particularly unique advantage of the Hydrohammer is the control system’s ability to shut off the ram (also check: BOP Ram) automatically if the pile starts to run ahead of the hammer in soft soils, e.g., due to

- The hammer is not positioned correctly on the pile.

- The stroke rate was becoming too high.

- Blow energy is too high.

Other advantages unique to this hydraulic hammer are:

- It can operate at any angle, even horizontally.

- It has an optional printer available to produce a report of the piling operation.

- It can be used in onshore or offshore rigs, in air, or submerged underwater.

Final Refusal Depth For Conductor Casing Pipe Installation For Oil & Gas Wells

The following procedure details the determination of the final refusal depth of the conductor casing pipe installation.

A. When the driving depth of the conductor pipe is not specified in the drilling program, the final depth of the driving is the ‘refusal depth.’

- The refusal value generally used is 1,000-1,100 blows/meter (300-330blows/ft)

- Local experience could dictate a different refusal value. We can predetermine the driving depth can by conducting a soil boring analysis.

- Examine offset well data for depths and potential problems to determine if the CP depth is adequate.

B. We can establish the installation driving depth of the conductor casing pipe which is specified in the Drilling Program, with the following formula:

Hi = [df x (E+H) – 103 x H]/[1.03 – df + 0.67 x (GOVhi – 1.03)]

Where:

- Hi = Minimum driving depth (m) from seabed

- E = Elevation (m) distance from bell nipple and sea level

- H = Water depth (m)

- df = Maximum mud weight (kg/l) to be used

- GOVhi = integrated density of sediments (kg/dm3/10m)

If the refusal depth does not meet this value, we may need to perform CP internal washing. CP internal washing might be necessary several times before reaching the planned depth.

C. Note: the CP shoe could collapse if there is a high refusal value in challenging formations.