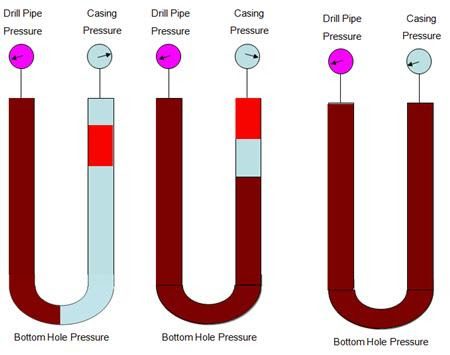

In Driller’s Method, the Kill is split into two circulations to fully control the well.

- During the first, the Kick fluid is circulated without changing the mud weight.

- During the second, once the Kick is out, the mud is weighted up and pumped around the well on the second circulation.

Advantages

- Minimum Arithmetic

- Minimum Waiting Around Time – can start Kill at once

- Minimum Information Required

Driller’s Method In Well Control Disadvantages

- This method is the longest of the three methods, with an increased possibility of choke problems.

- The annular pressures produced during the first circulation are higher than produced with any other method.

- Because very high annular pressure may arise when killing a gas Kick with this method, care should be taken. Annular pressure will be at a maximum immediately before gas arrives at surface, and casing burst pressure limitations may be critical.

Applications

This method is mostly used on small land rigs where the Driller (check also: driller job description) may have little help and limited equipment. It is also used on highly deviated and horizontal wells, where the influx is likely to be a swabbed Kick (you may be interested in Kick Tolerance Calculation, Definition & Formulae & kick warning signs).

In addition, the simplicity of Driller’s Method makes it useful when only limited information is available about the well control conditions.

Driller’s Method Procedures For Well Control

- The well is closed in with hard shut in procedure or soft shut in procedures and the information recorded.

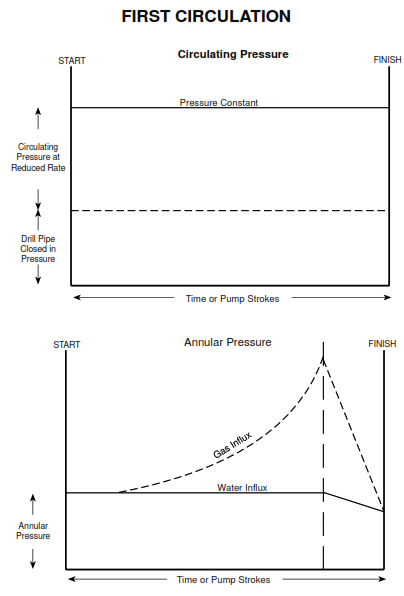

FIRST CIRCULATION

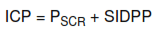

- If a slow circulating rate pressure, PSCR, has been taken, then calculate the pressure required on the Drill Pipe for the first circulation of the well.

This is:

- Open the choke about one quarter, start the pump and break circulation; then bring the pump up to the KILL RATE.

- While the Driller is bringing the mud pump up to the KILL RATE, the choke operator should operate the choke so as to keep the casing pressure at or near the SICP reading.

- Once the pump is up to the KILL RATE, the choke operator should transfer his attention to the Drill Pipe pressure gauge and adjust the choke to maintain the ICP on the drill pipe pressure gauge.

- The last step on well control driller’s method is helding the the ICP constant on the Drill Pipe pressure gauge by adjusting the choke throughout the whole of the first circulation, until all of the Kick fluid has been circulated out of the well. The pump rate must also be held constant at the KILL RATE throughout this period.

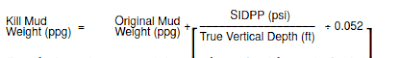

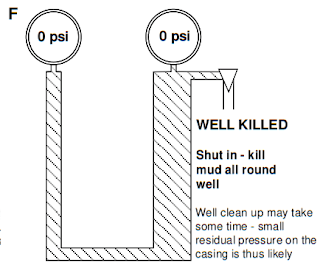

- Once the Kick is out of the hole, Shut the well in and mix up the kill mud weight required.

NOTE 1: This is a kill weight mud to balance formation pressure. It is the lowest possible mud weight which will kill the well. Once the well is dead, it will be necessary to increase the mud weight further to provide a trip margin.

NOTE 2: Some operators prefer to continue circulating the well while kill weight mud is being mixed. There is no theoretical reason why this should not be done, though it does result in further wear and tear on equipment under pressure – in particular the choke.

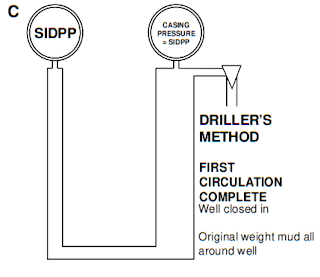

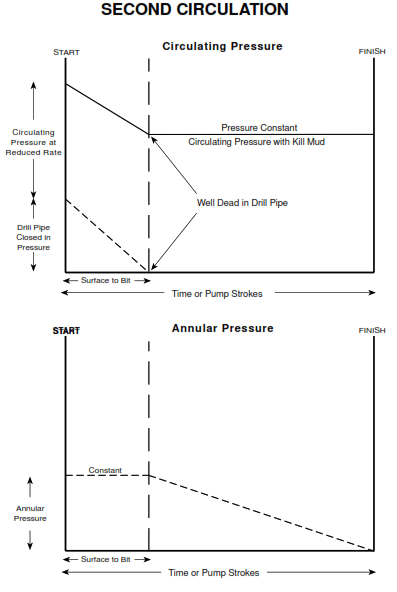

Driller’s Method Second Circulation

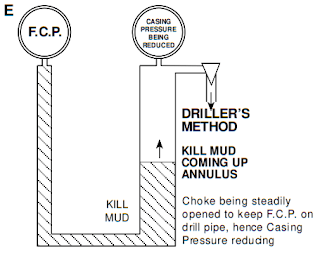

- Once the Kill mud is ready, open the choke about one quarter, start the pump and break circulation. Then bring the pump up to the Kill rate.

- While the Driller is bringing the pump up to the Kill rate, the choke operator should operate the choke so as to keep the casing pressure steady at the same pressure as when closed in.

- While the Drill Pipe is being filled with heavy mud there are two options for keeping B.H.P. constant, either keep the casing pressure constant or make out a graph going from I.C.P. to F.C.P.

NOTE: If the influx was gas and all the gas was not removed in the first circulation, the first option of keeping casing pressure constant could lead to higher annular pressures.

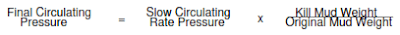

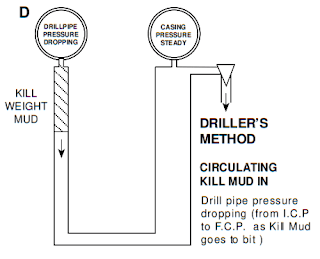

- The Drill Pipe pressure will go down as the Drill Pipe is being slugged with the heavier mud below the initial circulating pressure, as the Kill mud starts down the Drill Pipe, reaching the final circulating pressure when the Kill mud reaches the bit.

(In Driller’s Method practice, if all the Kick was properly removed in the first circulation, the choke should not need to be touched once the pumps are steady at the Kill Rate until Kill mud reaches the drilling bit.)

- Once the Kill mud reaches the bit, the Drill Pipe pressure is held at the final circulating pressure by controlled opening of the choke, as the Kill mud moves up the annulus.

(FCP: This is the slow circulating rate pressure, increased slightly for the extra mud weight)

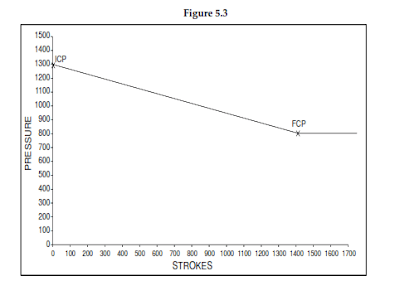

A graph showing how Drill Pipe pressure drops from the initial to the final circulating pressure is shown below and this can be used as a guide to the drill pipe pressures required. The drill pipe pressure should drop according to the graph, as kill mud goes to the bit, without the choke being moved.

Because of the possibility that the annulus may not be circulated completely clean, during the first circulation, it may be preferable to work out how the Drill Pipe pressure should vary as kill mud is pumped around the well.

This will allow the Drill Pipe pressure to be used throughout, so eliminating the possibility of small

gas bubbles in the annulus producing misleading information.

The following graphs depict the variations in pressure during the well circulation.

Determination Of ICP

If no slow circulating rate pressure has been taken, then the initial circulating pressure can be determined using the start-up procedures described in the circulations of the Driller’s Method.

Where the casing pressure has been held constant while the pumps are brought up to a kill rate, the Drill Pipe pressure reading will be the initial circulating pressure.

WARNING: the existence of a predetermined kill rate gives rig personnel a wrong impression that a Kick must be circulated exclusively at this rate.

The procedure consists of:

- Noting casing pressure reading.

- Adjusting pumps to new kill rate. Adjusting choke to hold casing pressure constant at the value noted.

- As soon as the driller has the pumps settled on the new rate, return to the Drill Pipe pressure gauge. Note this new reading is the circulating pressure for the new pump rate and maintain this.

- Check choke orifice size, in relation to kill rate

NOTE: This procedure is satisfactory at any time during a kill providing the mud weight in the drill string is not changing during the process. It is however preferable to maintain the pump rate constant as much as possible. Any decision to change the pump rate should be taken early.

Back To Other Well Control Methods