Soft Shut-in Drilling Definition & Lineup

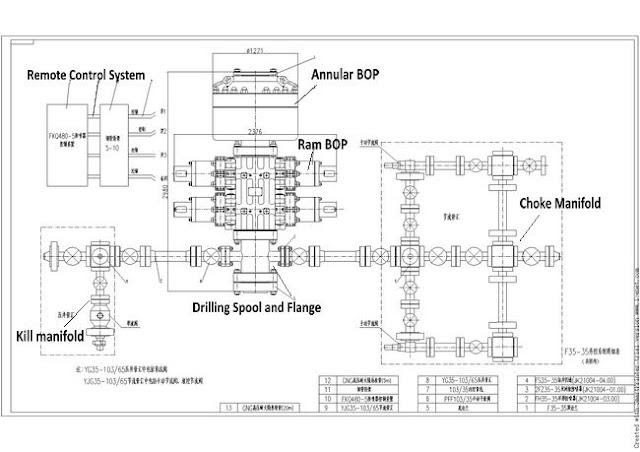

Soft shut-in is one of the procedures of closing wells after it gains a kick to its wellbore. For a soft close-in, a choke is left open at all times other than during a well control operation. The choke line valves are aligned such that a flow path is open through the choking system, with the exception of one choke line valve located near the blowout preventer.

When the soft close-in procedure is selected for closing in a well the:

- The choke line valve is opened.

- The blowout preventer is closed.

- The choke is closed.

Soft Shut-In Procedure in Fixed Rig

While Drilling

- When any indications are observed, while drilling, that the well may be flowing, stop rotating the drill string, and raise the drill string with mud pumps on until the tool joint is above the drill floor.

- Stop pumps and check for flow, if positive continue with the below steps.

- Open choke line HCR valve.

- Close blowout preventer.

- Close choke. If the choke is not a positive closing choke then close a valve downstream of the choke.

- Call drilling supervisors and commence plotting a graph of shut-in drill pipe pressure. Check pit volume gain.

While Tripping

Below, is the soft shut-in procedure while tripping pipe:

- If there is an indication of swabbing and the well flows during a flow check proceed as follows.

- Set the drilling slips.

- Install full opening safety valve (Kellycock).

- Close the safety valve.

- Open choke line HCR valves.

- Close BOP.

- Close choke.

- Call the supervisor and check the pressures.

- Install inside blowout preventer (Gray valve or Non-Return Valve).

- Open the safety valve.

- Reduce annular preventer pressure and start stripping operation for drill pipe in the hole.

Note: Choke in the open position while tripping.

Soft Shut-In Procedure in Floating Rig

While Drilling:

- When a possible indication is observed, stop the rotary and pick up the string to the predetermined height required for spacing out.

- STOP pumps. Check for flow. If positive.

- OPEN failsafe valve on BOP stack (valve on the choke line).

- CLOSE annular BOP.

- CLOSE choke. If this choke is not a positive shut-off type, it is necessary to close a valve ideally just downstream of the choke) in order to read well pressures.

- Alert supervisors. Check pit gain. Read and record pressures and times. If the pipe is to be hung off, some companies prefer to exchange the rig Kelly for a circulating head first. In this case:

- Set slips. CLOSE lower Kellycock. Bleed off pressure in Kelly. Remove Kelly, above lower Kellycock.

- Make up and install the circulating head. OPEN lower Kellycock. Remove slips.

- The last step in the soft shut-in procedure is to CLOSE top pipe preventer rams.

- Reduce the pressure on the annular preventer and lower the drill pipe until it hangs off on the top pipe ram. Note that it may be necessary to bleed off mud while lowering the pipe, to prevent well pressure increase due to the extra volume of the string being lowered into the hole. Bleed of mud to hold annulus pressure constant during this time.

- OPEN annular BOP.

While Tripping:

The following is the soft shut-in procedure while tripping:

- When a possible sign is observed, set the top tool joint in the slips.

- Install a full opening, fully opened safety valve in the drill pipe. CLOSE the valve once installed.

- Remove slips and pick pipe up to predetermined height for space out and check for flow and check trip volumes.

- OPEN choke line valve at BOP stack (failsafe valve).

- CLOSE annular BOP.

- CLOSE choke. If this is not a positive shut-off type, it is necessary to close the valve just downstream of the choke in order to read well pressures.

- Alert supervisors.

- Stab IBOP (Grey Valve) open safety Valve.

- Read and record pressures and times. Check pit gain.

- CLOSE upper pipe rams.

- Reduce pressure on the annular preventer and lower the drill pipe until it hangs off on a pipe ram.

Note: In the soft shut-in procedure, it may be necessary to bleed off mud while lowering pipe, to prevent well pressure increase due to the extra volume of the string being lowered into the hole. Bleed off the mud to hold annular pressure constant during this time.

- OPEN annular BOP.

Summary

- This soft shut-in procedure allows the choke to be closed in such a manner to permit sensitive control and monitoring of casing pressure buildup during closure. This is especially important if formation fracturing and broaching to the surface is likely to occur if the well is closed in without regard to the possibility of excessive initial closed- in casing pressure.

- The major disadvantage of the soft close-in procedure is that the additional time involved in opening the choke line valve and closing the choke will allow additional influx into the wellbore. This procedure will result in a larger kick volume and potentially higher casing pressure than obtained if the hard close-in procedure is used while circulating out the kick.

We recommend to visit this amazing comparison between hard and soft shut-in.

Ref: Aberdeen Well Control Manual