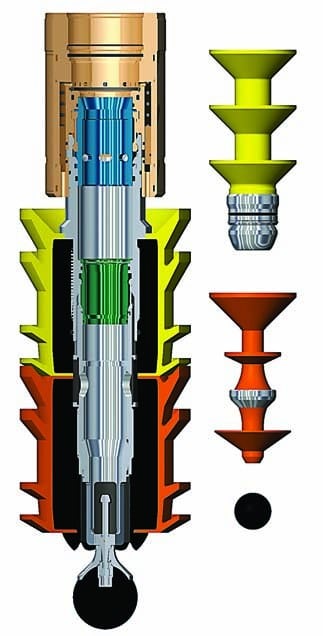

Cementing plugs are semirigid barriers that separate cement slurry from drilling fluids, wipe the casing, and indicate when cement placement is complete. Plugs were once made of gunnysacks, wood, and leather. Present designs include top and bottom wiper cementing plugs constructed of nitrile or polyurethane molded over PDC drillable high-density plastic cores (Fig. 1). The design of most plugs is nonrotating; as a result, they are easier to drill out (Fig. 2).

Application Of Top & Bottom Wiper Plugs

Although similar in external appearance, top and bottom plugs differ considerably in internal design and operation (Fig. 3).

Bottom Cementing Plugs

The development of bottom plugs aimed to precede the cement slurry, requiring an internal bypass or flow-through feature. The bottom plug features a thin membrane that will rupture and permit flow after setting of the bottom plug on the float collar. Bottom plugs also provide a seat for landing top plugs and sealing off displacement. To ensure compatibility, top and bottom plugs and float equipment should be from an ordinary manufacturer. Using bottom plugs with high LCM concentrations in the slurry can be risky because the LCM may tend to ball up ahead of the wiper plug and bridge the float valve.

Third Wiper Plugs

More recently, using a third wiper plug has become more common. The extra plug separates chemical washes or spacers from the drilling mud, keeping the pre-flushes clean before they enter the annulus. A second use of the third plug is to measure the displacement efficiency of the mud pumps. Because of casing-ID variances and pump-liner inefficiencies, the displacement volume sometimes varies from job to job.

With a three-plug system, we can measure the number of pump strokes necessary to bump the plug before pumping the cement slurry. This allows operators to pressure test the casing while the cement slurry is still fluid without damaging the cement-to-pipe bond.

Top Cementing Plugs

Occasionally, we use top plugs alone. Their design allows them to withstand the pressures and forces generated when landing abruptly. When using both top and bottom plugs, it is vital that we don’t launch them out of sequence. Because of the exterior similarity, top and bottom plugs generally have color codes. Pumping the top plug first means it will land and not rupture, leaving the casing full of cement. If this happens, the only recourse is to drill out the casing.

If using only a top plug, the top cementing plug will wipe any debris in the casing ID. Suppose the accumulation of debris is greater than the length of the shoe track (distance between the float collar and the bottom of the casing). In that case, this debris will be pumped into the annulus between the casing and the wellbore, contaminating the cement opposite the shoe track. This contaminated cement may result in poor cement quality around the shoe joint. We should always run a top and bottom cementing plug to help ensure a successful cement job.

Other Cementing Plugs Types

Other standard plugs include the following:

- Tapered plugs, used in multiple-ID strings

- Subsea plugs, used with subsea completions

- Latch-in plugs, used with latch-in equipment

- Flexible-fin plugs, used when passing through stage equipment.

Figure 4 shows one of the newest large-bore subsea wiper-plug-set designs. The new sets come with built-in swivel equalizers; we can release them with darts instead of balls. The reason for dart release is to provide wiping of the drill pipe strings on deep casings or casing liners and to avoid waiting for the gravity settling of balls. Figure 5 illustrates the operational sequence.

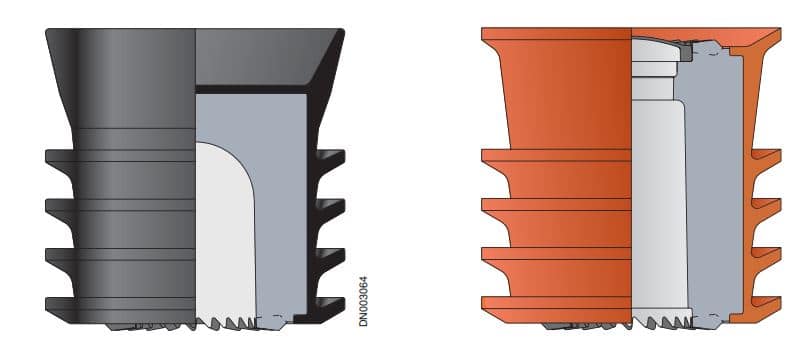

Halliburton High Wiping Efficiency Cementing Plugs

The HWE top and bottom cementing plugs are designed to help improve wiping efficiency during cementing operations (Cementing in drilling). The more efficiently the wiper plugs wipe the casing ID, the less fill will be left in the casing above the top cementing plug. The wipers of the HWE plug are a deep-cup design, which provides greater wiping efficiency. The bottom plug is supplied with a 750-psi rupture disc that helps ensure that the plug reaches the float collar. Because of its rubber molding, the HWE plug can run in water-based mud, oil-based mud, and synthetic mud systems.

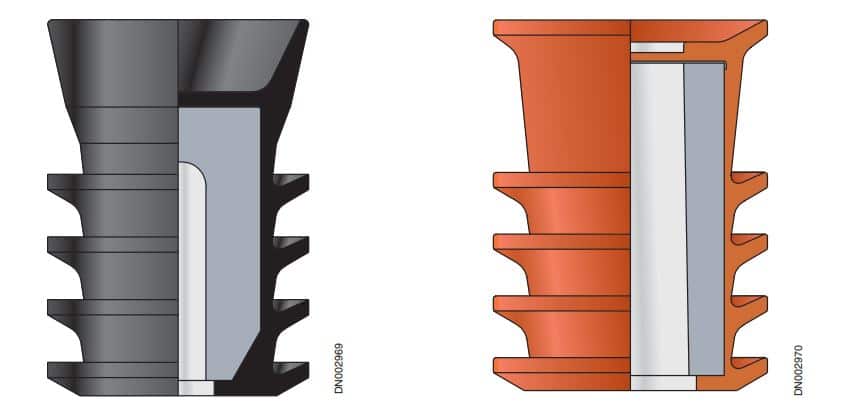

Halliburton Standard Five-Wiper Cementing Plugs

The five-wiper cementing plug is Halliburton’s primary cementing plug. Five-wiper plugs are available in 4 ½- through 20-in. casing sizes with standard plastic or aluminum inserts and 24-tooth NR plastic inserts in many sizes. In all types of five-wiper cementing plugs, the top cup of the top cementing plug is a deep-cup design that provides maximum wiping efficiency. The top plug is black, while the bottom is orange or red. When landing on the float collar, the bottom wiper of the bottom plug provides the seal for pressure shutoff. When landing on a bottom plug, the top plug seals on the bottom plug.

Halliburton Plastic Insert Standard FiveWiper Plugs

Five-wiper plastic insert plugs are molded with standard (water-based) rubber for use with water-based mud compounds and synthetic (oil-resistant) rubber for oil-based or synthetic mud systems. Proper cementing plug selection is essential to a successful cement job. Ensure that the proper plug is selected for the type of mud system in which it is to be run.

The proper plug should be supplied for the mud system in which it is to be run. If a new synthetic (usually oil or mineral oil) base is to be used, contact the Casing Equipment Group in Duncan, Oklahoma. After cementing, the plastic insert plug can be drilled out with either a standard roller-cone rock bit or a PDC fixed cutter bit.

Halliburton Aluminum Insert Standard FiveWiper Plugs

Aluminum plugs are made with aluminum core inserts and are available as top and bottom plugs. Aluminum insert plugs are supplied for water-based and synthetic (oil-resistant) mud systems. The proper plug should be supplied for the mud system in which it is to be run. After cementing operations have been completed, the aluminum-inserted plugs can be drilled out with a standard roller-cone rock bit. These plugs should not be drilled out with PDC bits.

Halliburton Nonrotating (NR) Cementing Plugs

Designed for use with Super Seal II™ NR float collars, top and bottom NR plugs have locking teeth that help prevent the plugs from spinning during drill out, which reduces drill out times and associated rig costs (check also drilling cost per foot). The high-strength plastic inserts used in NR plugs increase plug-landing pressures and allow easy drill-out with PDC and roller-cone rock bits. NR plugs are available for 7- to 20-in. casing sizes in surface release and SSR plug systems. NR plugs are made of a synthetic service compound compatible with water-based and synthetic mud systems. Five-wiper high-strength NR cementing plugs can be used with high-strength float collars to pressure-test casing immediately after the cement has been pumped and is still in the fluid stage. However, rubber compatibility should be considered when NR plugs are used with wiper cups to make combination plug sets.

References:

- Well Cementing Second Edition – Erik B. Nelson and Dominique Guillot