The IADC PDC Drilling Bits Classification Code system, developed by the International Association of Drilling Contractors, has been the representative voice of drillers worldwide since 1940. This system has enabled drillers to exchange information using standard nomenclature and dull grading methods for PDC drill bits and tricones. This system is not as widely used for PDC drill bits as for tricones, as the IADC system for tricones is used worldwide. However, it’s helpful to know the specifications for PDC drill bits.

Polycrystalline diamond materials, used in polycrystalline diamond compact bits, are among the most important material advances for oil drilling tools in recent years. Fixed-head bits rotate as one piece and contain no separately moving parts. When fixed-head bits use PDC cutters, they are commonly called PDC bits. Since their first production in 1976, the popularity of bits using PDC cutters has grown steadily, and they are nearly as common as roller cone bits in many drilling applications.

IADC Code For PDC Drilling Bits Classification System

IADC PDC Drill Bits Classification System Codes consist of 4 characters:

The First Character Of IADC PDC Drilling Bits Code

The first letter of the IADC Classification Code For PDC bits describes the PDC body material, and it is either:

1) M, which is for matrix body

“Matrix” is a hard, rather brittle composite comprising tungsten carbide grains metallurgically bonded with a softer, tougher, metallic binder. Matrix is desirable as a bit material because its hardness is resistant to abrasion and erosion. It can withstand relatively high compressive loads but, compared with steel, has low resistance to impact loading.

2) S for steel body construction.

Steel is metallurgically opposite of matrix. It can withstand high-impact loads but is relatively soft and, without protective features, would quickly fail by abrasion and erosion. Quality steels are essentially homogeneous, with structural limits that rarely surprise users.

The Second Character Of IADC PDC Drilling Bits Code

Diamond is the hardest material known. This hardness gives it superior properties for cutting any other material. PDC is extremely important to drilling because it aggregates tiny, inexpensive, man-made diamonds into relatively large, intergrown masses of randomly oriented crystals that can be formed into useful shapes called diamond tables. The second letter of the IADC Classification Code For PDC Bit describes the cutter density as it is known, as more you increase the number of PDC cutters, as more The PDC bit can drill harder formations.

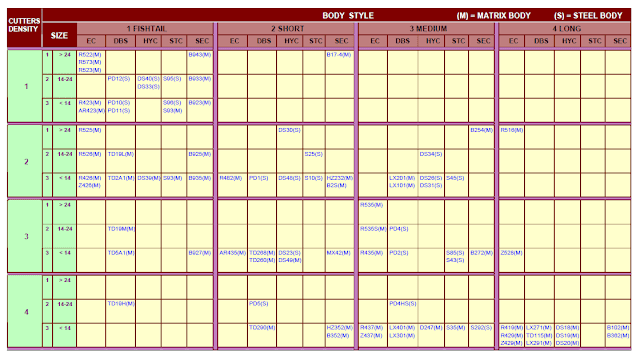

This IADC Code character ranges from 1 to 4 for PDC bits and 6 to 8 for Diamond bits, as shown below.

- For PDC bits: ranges from 1 for soft formations to 4 for hard formation

- 1 refers to 30 or fewer 1/2” cutters

- 2 refers to 30 to 40 cutters

- 3 indicates 40 to 50 cutters

- 4 refers to 50 or more cutters.

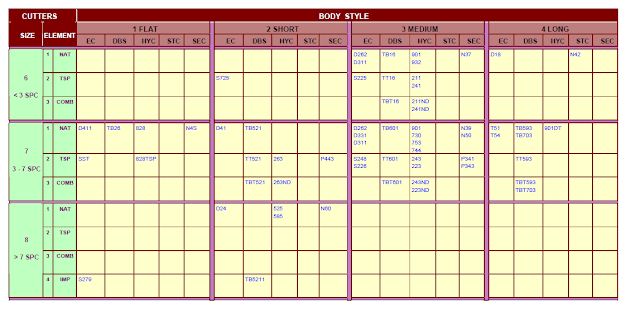

- For diamond bits: ranges from 6 for soft formations to 8 for hard formation

- 6 refers to diamond sizes larger than three stones per carat

- 7 refers to 3 stones to 7 stones per carat

- 8 refers to sizes smaller than seven stones per carat.

- Numerals 0, 5, and 9 are reserved for future use.

The Third Character Of IADC PDC Bit Classification

Generally, large PDC cutters sizes (19mm to 25mm) are more aggressive than small cutters. However, they may increase torque fluctuations. Smaller PDC cutters (8mm, 10mm, 13mm, and 16mm) have been shown to drill at higher ROP than large cutters in specific applications. One such application is limestone, for example. (refer to PDC Drilling Bit Design Article for more information)

Small cutters also produce smaller cuttings, while large cutters produce larger ones. Large cuttings may cause problems with hole cleaning if the drilling fluid cannot carry the cuttings up.

The third letter of the IADC Classification Code For PDC Bit describes the size of the cutter.

- For PDC bits

- 1 indicates cutter larger than 24 mm in diameter clay, marl, gumbo, and unconsolidated sands.

- 2 represent 14-24 mm,

- 3 indicates 13.3 mm (1/2”), and

- 4 is used for the smaller 8 mm in diameter.

The third letter of the IADC Classification Code For Diamond Bit describes the cutter type.

- For diamond bits: the third digit represents the diamond type.

- 1 indicating natural diamonds.

- 2 to TSP material.

- 3 represents mixed natural diamonds and TSP.

- 4 applies only to the highest density bit, indicating an impregnated diamond bit.

The Fourth Character Of IADC PDC Bit Classification

The Fourth Character Of IADC PDC Drill Bit Codes gives the basic description of bit’s profile. Bit profile affects both the cleaning and stability of the PDC bit. The two most widely used profiles are: Double cone & Shallow cone (refer to PDC Bit Design Article for more information)

This fourth letter of the IADC code ranges from 1 to 4, which:

- 1 represents fishtail PDC bits, ‘ flat’ TSP, and natural diamond bits.

- 2 & 3 & 4 indicate increasingly longer bit profiles

Useful Papers

PDC Drill Bit Specifications According to Steerability: Have you ever wondered how the introduction of rotary steerable drilling systems (RSS) has impacted the technical design of drilling bits? Nowadays, in order to ensure quick and accurate reactions to side forces applied by the steering system, bits must be specifically designed for directional systems like rotary bottom hole assembly (BHA), steerable downhole mud motor, or RSS. It’s fascinating to see how technology continues to evolve in the drilling industry!