In well control, the gas kick is simply to be detected once enter wellbore in water base mud as once driller (driller job description) shut in the well, the SICP & SIDP start to increase slowly with the same values due to gas migration. Of course, it may be difficult to notice such migration in oil-base mud as the gas solubility is higher in such medium.

Gas Kick In Oil Base Mud

1- Due to high temperatures and pressure, a small gas kick can turn into a serious well control problem with oil-base muds.

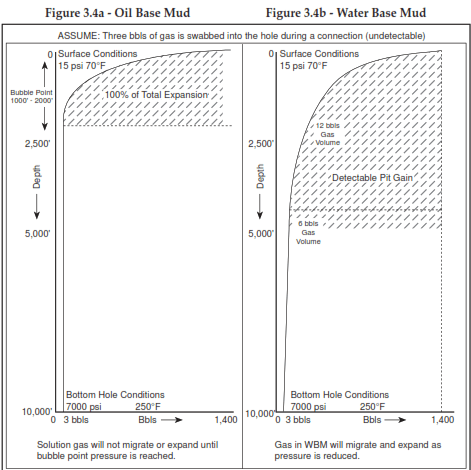

2- Gas Kick Behavior: Solution gas can become dissolved and miscible. The reason for this is that the gas remains in solution until it reaches its bubble point. In the same way that gas in a disposable lighter remains in its liquid phase until the pressure is relieved.

3- Example: In the above fig three barrels of gain have entered the wellbore at 10,000 ft

- Before gas reach 2600 ft, no pit gain while drilling .

- When the gas @ 2600 ft, The gas expands rapidly and there is a real danger of blowing out sufficient mud to put the entire well underbalance.

4- The problem in OBM’s is that if a gas kick has entered the wellbore undetected it is impossible to know where the top of the gas is (Learn more about kick warning signs, Causes Of Kicks)

5- Conclusion: It may be prudent to count all drilling breaks as primary indicators.

- Stop drilling

- shut off the pumps and

- close the well in.

- The gas can then be circulated through the choke in a safe manner utilizing the first circulation ofthe drillers method.

Some procedures advise that the gas should be circulated to 2500 ft. below the BOP Stack before the well is shut-in ( hard shut in procedures – soft shut in procedures) and the gas circulated through the choke manifold. It may be the case that the bubble point is lower and unless this information is known, even though the first procedure may take a little longer, remember safety is always our main concern.

Gas Kick In Water Base Mud System

In WBM systems because the original volume of the gas will expand much earlier as the pressure above the gas is reduced.

Gas Expansion

In (Uncontrolled) – (Well Open)

If a gas bubble is allowed to expand without control of any kind it will eventually unload the well. With the well unloaded, kick sizes increasing, causing more unloading. This cycle of influx and unloading has caused the loss of many wells.

Boyles Law is shortened version of the equation for gas expansion e.g. P V

P1V1=P2V2

P1 = Hydrostatic Pressure (W/Gas bubble on bottom)

V1 = Original Pit Gain

P2 = Hydrostatic Pressure at secondary depth

V2 = Gas Volume at the surface or at secondary depth

When Gas Kick In Solution – (Oil Base Mud)

Well Control problems can result in blowouts because of the solubility of certain gases in specific types of mud e.g. Methane dissolves in oil-base mud, and H2 dissolves in water base mud. This fact makes it more difficult to detect a kick.

A large gas influx entering the wellbore may change the pit level very little if the gas dissolves in the mud. The influx is then circulated up the wellbore in the mud column until the hydrostatic pressure on top of the gas decreases to a certain point then the gas flashes or bubble point is reached and gas comes out of solution.

Detecting the kick by observing flow-line or mud pits can be very difficult until the kick is very

close to the surface and expands rapidly. Moreover, gas dispersed in wellbore fluids does not migrate up the hole therefore a flow check may not show.

Gas Kick In (Well Shut-In) Situation

When a well is shut in on a kick that contains gas the gas will migrate up the hole even if the well is allowed to remain static.

In Well Control, Gas Migration happens THEN Rises THEN all pressures increases

Gas migration can cause confusion during a well control operation because it can be overlooked. Gas or Gas bubbles float or migrate up the hole because they are lighter than mud.

When gas bubbles rise they expand or if they are not allowed to expand they cause an increase in all wellbore pressures and surface pressures. Therefore if a well is shut-in for a long time, all pressures, wellbore surface, etc. will increase causing lost circulation, etc., if not relieved by allowing gas to expand.

So lowering SIDPP to original value through the choke and observing, keeping SIDPP at original value, will prevent this problem.

All pressures will increase during the migration of gas except pressure in an actual bubble which is usually at formation pressure.