When a well gains a kick, it is a big loss as the drilling supervisor and crew had to waste a lot of time trying to kick it out from the well. In this article, we shall learn the major seven causes for kick-in drilling oil and gas wells. As you get to this page, you might be interested in our advanced well control guide.

Major Kick Causes While Drilling Oil & Gas Wells

In general, the main causes of kicks while drilling are:

- Improper monitoring of pipe movement (drilling assembly and casing).

- Tripping pipe out – ensuring the hole takes the proper amount of mud.

- Trip in – ensuring it gives up the proper amount of mud and preventing lost circulation due to surges.

- Swabbing during pipe movement.

- Loss of circulation.

- Insufficient mud weight.

- Abnormally pressured formations

- Shallow gas sands

- Special situations.

- Drill stem testing

- Drilling into an adjacent well

- Excessive drilling rate through a gas sand

Surveys in the past have shown that a major portion of well control problems have occurred during trips. The potential exists for the reduction of bottom hole pressure due to:

- Loss of ECD in drilling with pumps off.

- Reduction in fluid levels when pulling pipe and not filling the hole.

- Swabbing.

Failure To Keep The Hole Full During A Trip

If the fluid level in the hole falls as the pipe is removed, the bottom hole pressure will be reduced. A kick may occur if the magnitude of the reduction exceeds the trip margin or safety overbalance factor. The hole must be kept full with a lined-up drilling trip tank that can be monitored to ensure that the hole is taking the correct amount of mud. It can be detected if the hole fails to take the correct mud volume. A trip tank lineup is shown below.

It is of the utmost importance that drill crews properly monitor displacement and fill up volumes when tripping. The lack of this basic practice results in many well control incidents every year.

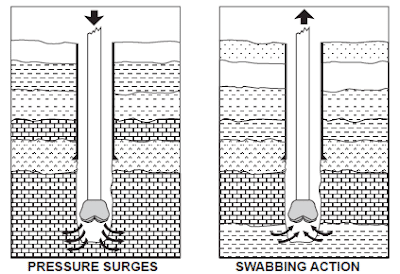

Surge and Swab in Drilling Can Cause a Kick

Swabbing is when the bottom hole pressure is reduced below formation pressure due to the effects of pulling the drill string, which allows an influx of formation fluids into the wellbore.

- When pulling the string, there will always be some variation in bottom hole pressure. A pressure loss is caused by friction, the friction between the mud and the drill string being pulled.

- Swabbing can also be caused by the full gauge downhole tools (bits, drilling stabilizers, drilling reamers, core barrels, etc.) being balled up (Check Bit Balling Definition, Causes & Prevention). This can create a piston-like effect when they are pulled through mud. This type of swabbing can have drastic effects on bottom-hole pressure.

Surging Effect

Surging is when the bottom hole pressure is increased due to the effects of running the drill string too fast in the hole. Downhole mud losses may occur if care is not taken and fracture pressure is exceeded while RIH. Proper monitoring of the displacement volume with the trip tank is always required.

The factors affecting swabbing and surging are:

- Pulling speed of pipe: Tripping speeds must be controlled to reduce the possibility of swabbing. It is normal practice for the Mud Logger (Mud logger Job Description) to run a swab and surge program and to make this information available to the Driller. This will provide ample information to reduce the possibility of an unforeseen influx.

- Mud properties: Controlling the rheology of mud is important. Controlling water loss to avoid thick wall cake will also help.

- Viscosity.

- Hole geometry.

Swabbing Effects:

Swabbing is a recognized hazard (Oil Rig Hazards) whether it is “low” or “high” volume swabbing. A small influx volume may be swabbed into the open hole section. The net decrease in hydrostatics due to this low-density fluid will also be small. If the influx fluid is gas, it can, of course, migrate and expand.

The expansion may occur when little or no pipe is left in the hole. The consequences of running pipe into the hole and swabbed gas must also be considered.

What Is The Trip Margin:

Trip margin is a safety factor to provide an overbalance to compensate for swab pressure can be:

Trip Margin Factor (psi/ft) = APL (psi) / True Vert. Depth (ft)

Where : APL in drilling = Annulus Pressure Loss

What is the first action After detecting a kick caused by the drilling swapping effect

We have 2 cases:

For the First Case – If the well is not flowing, then the following should be carried out:

- A nonreturn valve should be installed

- The bit returned to the bottom.

- Flow check each stand.

- Once back on the bottom, the well should be circulated, and the bottom sample should be checked for contamination.

Second Case – If the well is flowing or the returns from the well are excessive when tripping in, then the following should be carried out:

- Install a non-return valve. If there is a strong flow, a kellycock must be installed first.

- Shut the well in.

- Prepare for stripping.( check the stripping operations guide)

- Strip into the bottom.

- Circulate the well and check bottoms up for contamination.

Notes:

- Continuous monitoring of replacement and displacement volumes is essential when performing tripping.

- A short wiper trip and circulating the well before pulling completely out of the hole will provide useful information about swabbing and pulling speeds.

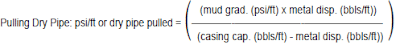

Useful formulas for calculating the pressure reduction per foot of drill pipe pulled are as follows:

Circulation Lost Problems

Another cause for a kick to occur is the reduction of hydrostatic pressure through the loss of drilling fluid to the formation during lost circulation. When this happens, the height of the mud column is shortened, thus decreasing the pressure on the bottom and at all other depths in the hole. So it is recommended to follow Lost Circulation Mitigation Procedures & avoid causes of lost circulation in drilling.

The amount the mud column can be shortened before taking a kick from a permeable zone can be calculated by dividing the mud gradient into the overbalance at the top of the permeable kick zone.

H (ft) = Overbalance (psi) / Mud Gradient (psi/ft)

Insufficient Mud Weight

A kick can occur if a permeable formation is drilled with a higher pressure than the mud column. If the overpressurized formations have low permeability, then traces of the formation fluid should be detected in the returns after circulating bottoms up. If the overpressured formations have high permeability, then the risk is greater, and the well should be shut-in (soft shut-in or hard shut-in) as soon as the flow is detected.

Abnormal pressured Formations

Definition Of Abnormal Pressure

Abnormally high formation pressure is any formation pressure greater than the hydrostatic pressure of the water occupying the formation pore spaces. Abnormally high formation pressures are also termed suppresses, overpressures, and sometimes pressures. More often, they are simply called abnormal pressures.

Abnormally high-pressure gradients will thus be between the normal hydrostatic gradient (0.433 to 0.465 psi/ft) and the overburden gradient (generally 1.0 psi/ft).

A further cause of kicks from drilling accidentally into abnormally pressured permeable zones. This is because we had ignored the Kick warning signs that occur. These help us detect abnormal pressures.

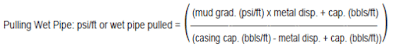

Abnormal Formation Pressure Causes Drilling Kick

In some areas, adequate sands were continuous and open into the sea or to the surface. In these areas, the water squeezed from the shale formations traveled through the permeable sands and was released to the sea or a surface outcrop. This dewatering allowed the formations to continue compacting, increasing their density.

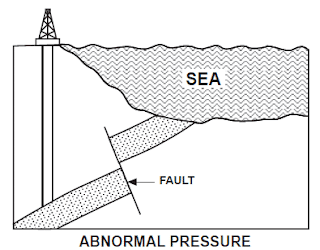

In other areas, or at other times, the sands did not develop or were sealed by deposition of salt or other impervious formations or by faulting such as we have indicated here. Although the shale water was squeezed, it could not escape. Since water is nearly incompressible, the shales could not compress past the point where the water in the shale started to bear the weight of the rock above.

This section caused a condition in which the weight of the formation – the overburden – was borne not by the shale alone but assisted by the fluids in the shale. In this situation, the shale will have more porosity, and a lower density than it would have had if the now-pressured water had escaped. These formations, both sand and shale, are then overpressured. If a hole is drilled into an overpressured formation, weighted mud will be required to hold back the fluids contained in the pore space.

The causes of abnormally high formation pressures are related to a combination of geological, physical, geochemical and mechanical processes

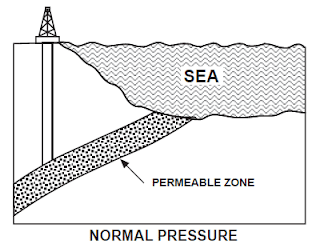

Drilling Shallow Gas Sands May cause a kick

Kicks caused by shallow sands (gas and water) whilst drilling in the top hole section with short types of casing strings can be very hazardous, as documented by many case histories.

Some of the kicks from shallow sands are caused by charged formations. Causes of charged formations:

- Poor cement jobs. ( Check how to perform successful primary cementing operations)

- Casing leaks.

- Injection operations.

- Improper well abandonment.

- Previous underground blowouts can produce charged formations.

Special Situations

Drill Stem Testing (DST)

The formation test is one of the most hazardous operations encountered in drilling and completing oil and gas wells. The potential for stuck tools, blowouts, lost circulations, etc., is greatly increased.

A drill stem test is performed by setting a packer above the formation to be tested and allowing the formation to flow. Downhole chokes can be incorporated in the test string to limit surface pressures and flow rates to the capabilities of the surface equipment to handle or dispose of the produced fluid.

During the test, the borehole or casing below the packer, and at least a portion of the drill pipe or tubing, is filled with formation fluid. After the test, this fluid must be removed by proper well control techniques to return the well to a safe condition. Failure to follow the correct procedures to kill the well could lead to a blowout.

Drilling Into an Adjacent Well

Drilling into an adjacent well is a potential problem, particularly in offshore rigs where many directional wells are drilled from the same platform (Platform Rigs). If the drilling well penetrates the production string of a previously completed well, the formation fluid from the completed well will enter the wellbore of the drilling well, causing a kick.

If this occurs at a shallow depth, it is an extremely dangerous situation and could easily result in an uncontrolled blowout.

Excessive Drilling Rate Through a Gas Sand/Limestone

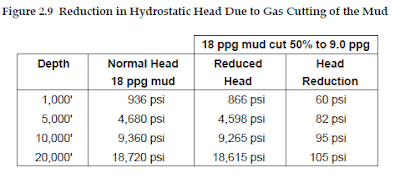

When drilling a gas-bearing formation, the mud weight will be gas cut due to the gas breaking out of the pore space of the cuttings near the surface. The severity of the influx will depend on the penetration rate, porosity, and permeability and is independent of mud weight.

The importance attached to gas cutting is that gas is entering the wellbore in small quantities, which calls for caution. Degassing is necessary to ensure that good mud is being pumped back into the hole to prevent the percentage of gas from increasing with each circulation, allowing greater and greater bottom-hole hydrostatic pressure reductions.

Most mud cutting is close to the surface. Divert flow through choke manifold to prevent belching and to safely contain gas through mud gas separator. Time drill the gas cap to prevent severe gas cutting of mud.

Gas cutting alone does not indicate the well is kicking unless it is associated with pit gain. Allowing the well to belch over the nipple could cause a reduction in hydrostatic pressure to the point that the formation would start flowing, resulting in a kick.

Ref: Aramco Well Control Manual