Jack up Operations & rig move procedures that we will talk about in this article include the following:

- Jacking systems

- Pre-drilling operations

- Operational design requirements

- Other operational matters

Jacking System

Jacking systems can be grouped into two main generic types: the rack-and-pinion system and the yoke-and-pin system, the first being more common. Within these types, there are two main designs: floating jacking design and fixed jacking design:

Rack And Pinion System

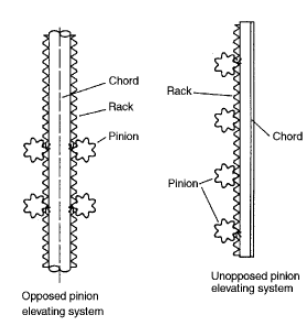

The most common type of elevating system is the rack and pinion. This is a simple, easy-to-operate system consisting of large gear wheels which, when turned, run along the vertical toothed racks attached to each of the legs, thus jacking the rig up or down. The pinions can be employed in pairs on either side of the leg member (opposed pinion) or on one side of the leg only (unopposed pinion). Typically a jacking speed of 0.5 m/minute can be achieved. This system is easy to activate, easy to cycle up and down, and it is easy to change out motors and other equipment.

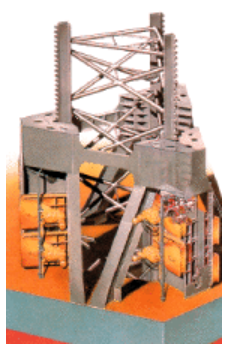

Figure 1 shows a schematic of both systems, and Figure 2 is an example of an unopposed pinion system.

Yoke-And-Pin System in Jack Up Operations

Yoke and pin jacking systems utilize hydraulic rams to jack the rig up in stages, using slots on the legs to locate the hydraulic rams. This system has long cycle times. Changing out jacks or hydraulic equipment can be very difficult, and it is not easy to change direction.

Floating Jacking Design

The floating method employs resilient snubber pads mounted on the top and bottom of the jacking unit. Jacking forces are transmitted through the pads into a jack housing structure and the hull. As the attachment is not rigid, the jacking unit can free-float within the confines of the leg guides. In this method, the jacking unit is guided to the leg allowing more liberal tolerances in leg construction.

Fixed Jacking Design

The fixed mounting method uses a welded connection of the jacking frame to the vessel hull. This provides a rigid mounting in which loads are transmitted through the jack frame directly to the hull. The frame is restrained by diagonal bracing and cross-ties to form a rigid support around the leg. While requiring close tolerances in leg fabrication and hull guides, this method eliminates the need for a jack house structure and reduces leg weight by the nature of the applied design load.

Pre-Drilling Jack Up Operations

There are two main operational periods for a jack up. The first includes;

- Jacking down

- Transit to a new location

- All operations at the new location until the offshore drilling rig is jacked up and considered stable and safe for drilling operations

The second period encompasses all drilling operations from this work platform (Platform Rig).

Statistics show that jack up operations risk increases sharply whenever the rig is being moved. This is due to two main factors: design and personnel. A jack up is designed primarily as a stable drilling platform and hence somewhat limited in its seaworthiness while in the floating mode. This section lists and explains the major operational procedures for a jack-up drilling unit.

Jacking Down

Before commencing a rig move, all loose rig components & equipment items must be secured, and all hatches and water-tight doors closed.

Towing vessels for moving jack up rigs should be sufficient in number and power to control the position and heading of the rig at all times and to ensure a positive speed in the worst foreseeable sea conditions.

During rig moves, a Tow Master or Marine Representative is usually present on the jack up and in charge of the tow. However, rig drilling supervisor, the appointed O.I.M. & toolpusher will still be responsible for the overall safety of the rig.

Stability calculations must have been completed to ensure the drilling rig is within the allowable limits, and everyone, including the Captains of the towing vessels, should have agreed upon the move program.

Once the hull has been lowered to a 2-meter air gap, the weather is again reviewed along with the forecast and trend, which has been monitored for the last 48 hours. The tugs can then be positioned. Ideally, one on each corner, and the hull lowered further into the water to a 2-meter draft. Checks for leaks should now be completed before proceeding further.

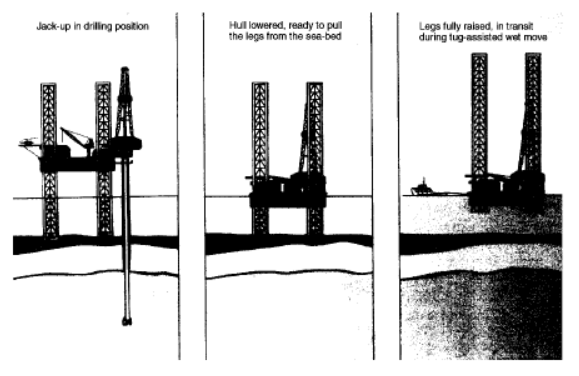

The legs can now be jacked higher, and the mat or legs pulled off the sea bed (see Figure 3). This may take several hours or even days if there is much penetration. If this is the case jetting can be used while holding tension on the leg(s). This procedure reduces the freeboard of the rig, which should be carefully monitored. If this is unsuccessful or the jets become blocked, the legs can be “levered up” by flooding ballast tanks on the opposite side of the stuck legs.

During this leg-pulling jack up operation, the tugs are kept on station with a slack towline, except for the one on the weather side, which may pull to equalize the combined wind and current loads.

The phase of moving off location is especially critical if there are sub-sea wellheads or X-mas trees in the vicinity. If strong currents and or winds are present, the rig will rapidly drift off location if great care is not taken. Towing vessels should be utilized to maintain the rig’s position until the legs are sufficiently high to clear any sea bed obstructions. If control is lost, with the spud cans just off the bottom, there is a good chance of damaging spud cans, legs, or sub-sea installations.

Towing Operations for Jack Up

There are two different options for towing a jack up between locations: the wet tow and the dry tow.

Wet tow

During a wet tow, a jack up rig move between locations is in floating mode with the legs up and is assisted by one more towing vessel. Wet tows are the most common method of inter-field rig moves of a jack up drilling unit and are by far the most practical, even over relatively long distances.

Raising the legs fully may not be necessary for rig moves within a field. For longer tows, however, the legs should be fully raised to reduce drag through the water and thus ensure maximum towing speed.

Constant communication between the lead tug and the jack up control room should be maintained during the tow. The lead tug should regularly provide the position of tow, course, and speed to the control room. If appropriate, there should be a liaison with the coast guard, and the tow should be carried out along shipping lanes.

Inspection of the rig encompassing decks, engine rooms, and tank soundings should be completed at least two hourly, and the observations logged. The trim and motion of the rig should also be monitored, and any slight change should be investigated. Navigational lights should be on and checked to be clear, and foghorns tested.

When planning a long tow, locations along the route suitable for jacking up the rig should be identified and surveyed. In the event of deteriorating weather or other problems during the tow, the rig can be jacked up before reaching its final destination.

Dry tow

Dry towing, where the jack up is placed on the deck of a large transport ship (Figure 4), is used for long, e.g., intercontinental, rig moves primarily because the transportation speed and vessel stability are significantly increased.

The economics of dry tows are dependent on several factors, such as:

- Availability of suitable vessels in the area

- Distance to be transported

- Anticipated weather conditions en route

- Contractual obligations

- Possibility to share the transport vessel with other operators

There are vessels now on the market that can carry several large rigs (jack ups as well as any other type of mobile rig) at once, and if one can plan far enough ahead to utilize such vessels, then significant savings will be made.

Jack Up Operations At The New Site After Move Till Spud

Site Surveys In Jack Up Operations

Before the rig move of the jack up to a new location, it will be necessary to have a site survey of the proposed location completed. This survey is necessary for the offshore drilling rig companies and insurance oil and gas companies to ensure that the sea bed suits the rig. The survey will usually encompass an area of a 0.5 km radius around the proposed location and will investigate the following:

- Water depth

- Debris check of the sea bed

- Shallow seismic of sea bed indicating depth of silt and expected firm base (also the presence of shallow gas)

- Evidence of sandbanks or significant unevenness of sea bed

- Location of pipelines, wellheads, or wrecks in the vicinity

- Shipping lanes

- Soil sampling

It will generally be necessary to complete the site survey 3-4 weeks before the rig moves to the location so that all relevant parties can analyze the results.

Arriving On Location

Upon arrival on location, the rig should be slowed by the tugs, which can then be connected one to each corner, to hold the rig stationary and on the correct heading while pinning down (the point at which the legs initially penetrate the sea bed).

However, this is not always easy, as holding the exact position and heading, possibly against a current, requires a high degree of coordination between the tugs and the rig, simultaneously lowering its legs. This is especially critical when the location is over a platform or if pipelines are nearby, where loss of control could cause severe damage.

Positioning can be achieved by combining tug(s) and anchors; if it is known that the anchors will hold in the prevailing sea conditions, this may be the preferred method.

Two anchors should be run astern, one on each corner, before the rig is too close to the platform. The tugs then apply a slight pull ahead to restrain the rig, which is drawn back to the desired position by the anchor winches. The rig can be maneuvered with high control and precision using this procedure. If the anchors should drag, the rig will be pulled away from danger by the tugs.

The boats are kept tied up, hanging slack until the pre-preloading-completed, and they are no longer required. These maneuvers should always be performed in daylight.

Pinning

The term ‘pinning’ is used when the legs of the jack up are set down on the sea bed at either the desired or standby location and refers specifically to the point at which the legs start to restrict the free movement of the barge.

Jacking Up Operations

Once the rig is in the correct position and held by the tugs and anchors, the legs can be jacked down until they penetrate the sea bed. The jacking continues progressively, keeping the rig level until the hull is clear of the water by 1 to 3 meters, depending on the sea state. The legs may not all penetrate to the same depth.

The sea bed at some locations, especially around fixed structures, will often have pipelines and or footprints of previous jackup rigs present. The position of these hazards should be known, and if there is any doubt, divers or an ROV can be utilized to check the location and possibly even monitor the situation while the jacking is in progress.

Pre-Loading

To achieve satisfactory rig stability on the sea bed, maximum anticipated vertical leg loads are simulated on each spud can before jacking up to full operational air gap. The pre-loading operation is necessary to ensure that all spud cans are sitting on a firm base and that no further settlement is likely to occur. This foundation must be strong enough to withstand the combination of maximum environmental loads, maximum variable, and drilling/operational loads without further settlement or ‘punch through’.

Pre-loading is the most critical test procedure on a jack up and should be carried out thoroughly and without compromise.

Pre-loading only emulates the vertical load on the spud cans. In real storm conditions, the spud can experience the maximum vertical load in combination with a significant horizontal load referred to as base shear. This combination of loads may subject the sea bed beneath the spud cans to a higher effective load than that imposed during pre-load. In an attempt to compensate for this, a pre-load safety factor can be employed. The safety factor of 1.3 is applied to the environmental component of the calculated pre-load requirement.

Pre-loading three-legged jack up rigs is achieved by filling selected hull tanks with seawater and holding this additional load until gradual settlement by each leg into the sea bed has ceased. This settlement can be easily monitored by watching the levels in the control room. Jack up rigs with four or more legs are pre-loaded by alternate and repeated tensioning of diagonally opposed legs. Pre-loading with four legs is much quicker than preloading with three legs.

The air gap must be kept to a minimum during pre-loading to minimize damage caused by sudden punching through one or more of the legs.

Other Operational Matters Related To Jack Up Operations

Anchors

Jack ups normally have a relatively small anchoring system which, as mentioned, is usually only used when moving on or off a location where exact positioning is critical. This could, for example, be while moving on or off an existing wellhead or sub-sea tree or moving over or away from a production platform.

Normally, when a rig is positioned over a ‘virgin’ location, it is satisfactory to ‘pin’ the rig, with tow boats holding it at the proposed location. With modern positioning equipment, a positioning tolerance of 15 meters radius is standard. This tolerance can, however, be reduced by pinning the jack up rig at a standby ‘move-on’ location in the vicinity of the intended site while the tow vessels run the anchors. The rig is then jacked down, pulling the legs from the sea bed, and positioned accurately using anchor winches. At this point, the rig would be pinned on the final location, and the anchors retrieved after pre-loading is completed.

Punch Through

Punch through is the term used to describe a sudden breach of the sea bed by one or more spud cans. Punch-through would almost certainly only occur during pre-loading and is rare as the site survey would normally have identified the potential for punch-through.

Punch-through can cause extensive damage to a jack up and emphasizes why it is necessary to perform the pre-loading fully at as small an air gap as practical, usually 1 to 3 meters.

Air Gap

The air gap is defined as the distance between the bottom of the hull of the jack up and the Mean Sea Level (M.S.L.). This distance is calculated to account for prevailing weather conditions in an area, such that the rig hull is far enough out of the water to avoid the hull being subjected to wave loads in the event of a heavy storm. As an indication, most jack ups will use an air gap of 15-30 meters, dependent on area, time of the year, and local conditions. This should be checked for each local operating area with the Marine Department.

Soil Mechanics

The soil strength that the spud cans of a jack up must sit on will significantly influence the cans’ design and the rig’s ultimate loading potential. Most soil types are a mixture in varying proportions of three types of solids defined by their particle size:

- Clay: particle size smaller than 0.005 mm

- Silt: particle sizes between 0.005 mm and 0.05 mm

- Sand: particle sizes between 0.05 mm and 2.0 mm

When overloaded, soils will fail in shear. The resistance to failure is called the shear strength of the soil. Soil samples can be taken from the sea bed and checked in the laboratory to determine their shear strength. The absolute shear strength is determined by the makeup of the soil and the amount of inter-particle air, gas, or water present. As soil is loaded with a spud can, the soil is compressed, and the inter-particle air, gas, or water is eventually forced out. This process might take days or weeks to reach equilibrium, explaining why a jack up might settle whilst in operation without causing great alarm. Generally, this type of settlement should be reasonably even over each leg. If gross differential settlement occurs (meaning the legs settle by essentially different amounts), then this could signify a more severe condition and should be further investigated.