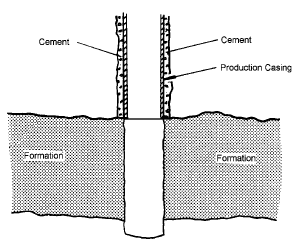

The casing is placed in the open hole completion type and cemented above the productive interval(s). Further drilling extends the well bore into and/or through the reservoir(s) left uncased, hence the term ‘Open Hole’; See Figure below.

All open-hole completions avoid the cost and complexity of perforating but have their complications.

Advantages

This type of completion is standard and find application in competent formations such as dolomite & limestones. They have several advantages beyond their obvious low cost.

- Water or gas shut-off is difficult in any completion but is more accessible in a barefoot well than in a pre-drilled casing liner well. (by an open-hole bridge plug backed up by cement).

- They are especially applicable to techniques such as through-tubing drilling (TTRD).

- They have wide use in simple multilateral wells.

- No formation damage from cement

- We can quickly deepen or sidetrack the well without screens or liners.

- We can convert it to liner-type completion.

- Large flow area.

Disadvantages Of Open Hole Completion

Compared to other completion types, the main disadvantages are:

- The inability to deploy upfront zonal isolation techniques such as swellable wells packer or ECP (external casing packers).

- Hole collapse probability

- We can’t control producing excessive water or gas.

- It is challenging to deploy zonal stimulation.

Formation Damage In Open Hole Completion

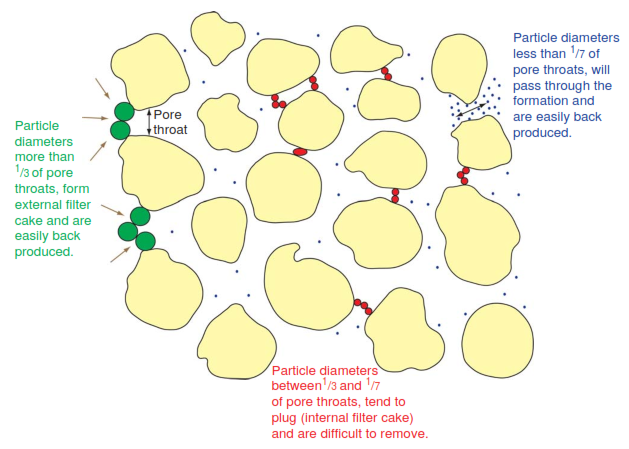

This type of completion is inherently prone to formation damage caused by drilling. The filtrate should generally be designed to avoid chemical interactions with the reservoir fluid or rock – particularly clays- and should be free of ‘plugging’ particles. In general, we should consider that all solids in any fluid that will contact the production zone should either be of bridge type or don’t cause plugging. This process is shown in Figure 3.

External filter cake is easier to back produce than internal filter cake. Removing the filter cake in an open hole, non-sand control completion should require opening the well to production and flowing the filter cake through the predrilled liner or other reservoir completion.

Filter cake clean-up with a pre-drilled liner should be easier than for a sand control completion as the filter cake can be designed to flow back through the completion – no gravel or screens in the way. Drawdowns with consolidated formations are usually higher than the equivalent poorly consolidated reservoirs.

References & Downloads

- Baker Manual For Open Hole Systems

- WELL COMPLETION DESIGN By Jonathan Bellarby, SPE (Society of Petroleum Engineers), NACE International and TRACS International Consultancy Ltd. Aberdeen, UK