A retrievable packer Can be defined as a subsurface tool that runs as a part of the completion string to provide a seal between the casing and tubing and can also be set and retrieved with wireline, mechanical or hydraulic mechanism.

The major difference than other types of packers (permanent packers) is that they can be removed from the well by tubing manipulation or some other means not involving the destruction of the packer. A limited number of production packers are available for wireline.

Applications

Retrievable packers tend to be used for the following applications:

- Short life completion.

- Where there is likely to be workovers requiring full bore access.

- Multi-zone completions for zonal segregation.

- Cement Squeeze

- Casing leak detection

- In relatively mild well conditions.

Setting & Releasing Mechanisms

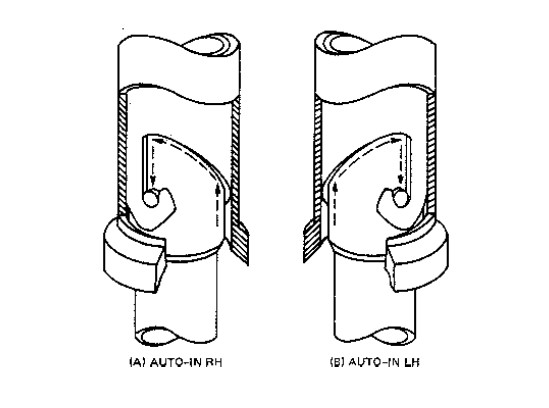

The setting mechanism generally consists of a J-latch, a shear pin, or some other clutch arrangement to allow the packer to be engaged. The various mechanisms employed are actuated by a number of different methods, including upward or downward movement, placing weight on the packer, pulling tension in the tubing, or rotating to the right or left. Hydraulically actuated retrievable packers are set with pressure inside the tubing using pump-out plugs, wireline plugs, or flow-out balls. The releasing mechanisms on a retrievable packer involve another wide range of actuation methods – straight pickup, rotating to the right or left, slacking off and then picking up, or picking up to shear pins. To select a particular type of setting or releasing mechanism, it is necessary to know the conditions existing in the particular wellbore when the packer is set and the operations anticipated during its stay in the hole.

Figure 1. Right-hand (a) and left hand (b) J-slot MechanismPros & Cons

The main advantage of retrievable packers is that they can be retrieved without destroying the packer. This saves drilling rig time and the cost of replacing the packer. If the old packer is in satisfactory mechanical condition and is not corroded it can be redressed and rerun in the well. Retrievable packers, however, cost more than permanent Type. Sometimes they get stuck (pipe sticking) and cannot be retrieved by conventional retrieving tools. In this case they have to be milled and retrieved by taper tap. Retrievable packers generally take longer time to mill (milling operations) than permanent type because their slips are made of harder metal.

Baker Hughes Retrievable Packers

An example of the later is the RETRIEVA – range of packers produced by Baker. The range features Models D, A, and B and is largely based upon the principle of using an opposing pair of slips to prevent upwards or downwards movement of the packer. The packer is usually retrieved by a straight pull on the tubing.

Model R-3

The Baker Model R-3 is a compression set packer that features a set of lower slips beneath the 3 element seal system and optionally an upper set of hydraulic hold-down buttons (double grip or single grip systems). It has applications for a range of production wells where low to moderate bottom hole pressures can be anticipated. The packer is set by pulling up at the setting depth, applying right-hand rotation, and slackening off weight. Retrieval requires only an upwards pull to unseat the packer.

Lok-Set Retrievable Packer Model

The “Lok-Set” range of packers (Baker) uses a system of slips to oppose upwards and downwards movement and these are located beneath the 3 element sealing system. The packer is claimed to have application for withstanding differential pressures in either direction and does not use hydraulic hold-down. The packer is run on the tubing to the setting depth and set by rotation. In sequence, the packer requires 6000 lbs setdown weight with rotation to release and set the upper slips, followed by 10-12000 lbs to release lower slips, and finally 6-10000 lbs to lock the seal element. To release and retrieve the packer requires up strain and right-hand rotation.

Model G

A simple compression set packer is provided by the Model G (Baker). To set the packer, it is run down to 1 ft below the setting depth, picked up to the setting point, and after 1/4 turn right-hand rotation, the weight is slackened off. To retrieve the packer requires only an upwards pull.

Baker FH Hydrostatic Retrievable packer

Hydraulic set retrievable packers offer a very useful facility since they allow flexibility and simplicity in completion operations, particularly in deviated wells where mechanical reciprocation may be ineffective and undesirable. The Baker FH hydrostatic packer is run as an integral part of the tubing string and is set by pressure generated within the tubing against a ball and seat sub or a plug located in a nipple. Normally 1000 psi pressure above the annulus pressure will shear the screws and actuate the hydraulic setting mechanism although this can be increased to 2000 psi if required. The ball and seat sub will be set to shear at 3500 psi in the event of the higher setting pressure being used. The packer is normally unseated by applying an upwards pull in excess of 30000 lbs.

Halliburton Retrievable Packers

Otis Model

Like Baker, Halliburton also offers a range of retrievable packers. The Otis Permatrieve is designed to offer a similar capability to a permanent packer with the provision of a slip system both above and below the 3 element seal system. The Perma-trieve can be run and set on the electric wireline, hydraulic, or on tubing with rotation. The retrieval of the packer can be accomplished without milling using either tubing or nonelectric wireline. The opposing slip principle gives the packer the ability to withstand high differential pressures from above or below.

Hook-Wall Model

Halliburton also offer a hook-wall packer which is retrievable with or without a hydraulic hold-down button, types MH-2 and MO-2 respectively. Both packers are designed to be run and set on the tubing. The packer is run to the setting depth, picked up, rotated 1/3 turn to the right, and setting down 8000 lbs weight. Retrieval requires a straight upwards pull to unseat the packer. The type MH-2, with the hold-down buttons, will be suitable where differential pressures exist from above or below the packer, i.e. if higher pressure exists in the annulus then it will support the weight set mechanism. However, if higher pressure exists below, it will actuate the hold-down button.

RH – RDH – RTH Models

Hydraulic set retrievable packers are also available as a single string (type RH), dual string (type RDH) and triple string (type RTH) from Halliburton. These packers utilize a set of slips below the 3-ring sealing element with hydraulic hold-down buttons above it. These packers are set with a differential pressure in the tubing which can be preset to between 800-3500 psi and is released by an upward pull. Several other vendors offer a competitive range of retrievable packers.