Permanent packers as the name implies are well packers, when set, cannot be retrieved from the well. General characteristics common to permanent packers include:

- Permanently set. Once set, they cannot be released and retrieved from the well. A milling tool is required to remove a permanent packer from the well. The milling process will “mill over” the packer’s slips thus destroying them. The packer may then be pushed to the well’s bottom or retrieved to the surface.

- No weight or tension requirements. Once set, no tubing weight down on or tension against a permanent packer is required to keep it in the set position.

- Economical. They have, by design, very few components. As a result, these packers are less costly than other packers of comparable size and composition.

- Highest pressure rating. Permanent type, due to their simple design and few components, can be built sturdier than other types of packers. Pressure differential ratings as high as 15,000 psi are possible.

- High-temperature rating. Element packages are available to withstand temperatures in excess of 500oF.

- Popularity. Worldwide, They are the most frequently used of all packers type.

- Seal assembly is required and accessories can be used with these types of packers.

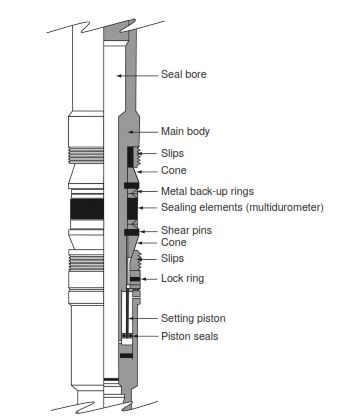

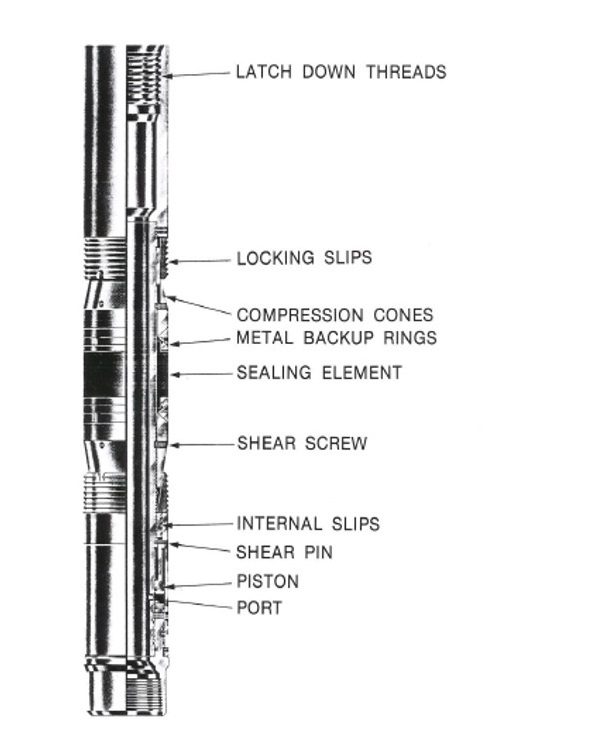

Components of Permanent Packers:

Typically, They will have specific components according to their manufacturer and their design, but most of the time you shall find certain items in each permanent packer as follows:

- Seal bore

- Main body

- Slips

- Cone

- Metal back-up rings

- Sealing elements (multi durometer)

- Shear pins

- Lock ring

- Setting piston

- Piston seals

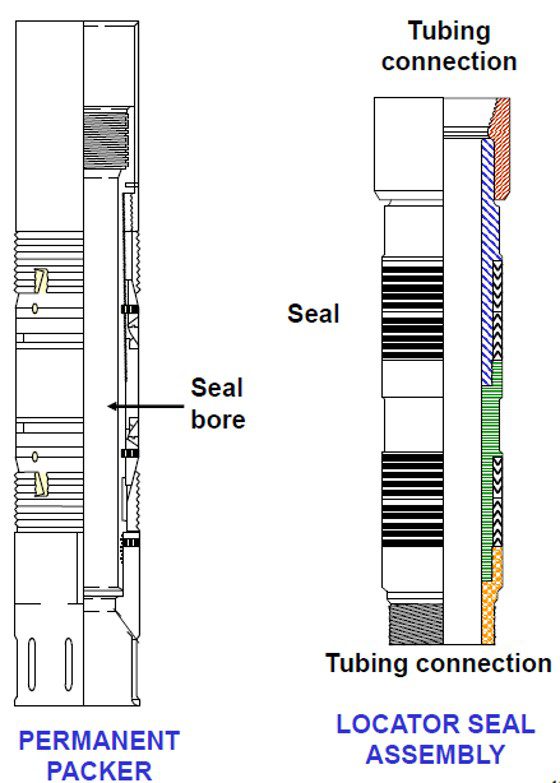

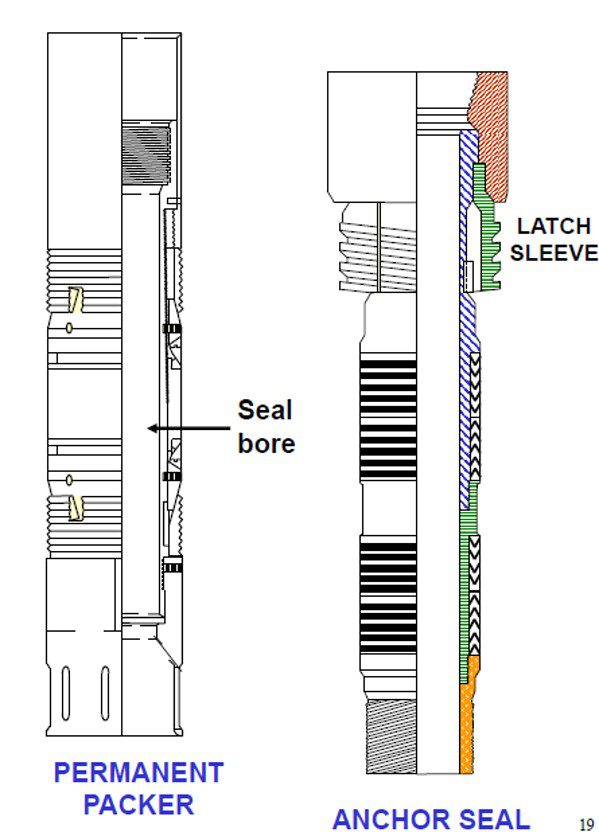

Seal Assembly

Since a permanent packer cannot be pulled out of the well, the tubing cannot be attached directly to a permanent packer. Occasionally, the tubing may have to be retrieved and repaired or replaced. However, a pressure-tight seal must exist between the tubing and packer bore forcing production into the tubing. This is accomplished by using a seal assembly that attaches to the tubing and seals off in the packer.

Seal assemblies vary greatly in length, elastomer composition, and metallurgy selection, again depending on downhole conditions.

The basic seal assembly consists of a locator, a seal unit, and a mule shoe guide.

The locator is designed to prevent any further downward travel of the pipe once it has encountered the head of the packer. The two standard locators are the (1) straight-slot locator and the (2) jay- slot locator.

- The straight slot locator is used when a “free-to-move” seal assembly is required such as in cases where large forces and tubing movement is anticipated.

- The jay-slot locator is used in situations where small forces and little tubing movement is expected. The “jay” slots of the locator latch into the lugs in the packer’s head preventing motion.

The seal unit forms a seal into the packer’s bore. Hole conditions may permit the use of a standard molded seal unit or require a premium seal unit to be used. Standard molded seals units are used in wells where pressures differentials are less than 10,000 pounds per square inch and temperatures are less than 275oF.

Premium seals are used for harsh conditions – high temperatures, high pressures, and severe environments such as hydrogen sulfide, carbon dioxide, amine inhibitors, and steam injection.

The sole purpose of the mule shoe guide is to facilitate the entry of the seal assembly into the packer bore. The overall length of a seal assembly can be adjusted by the number of seal units used and the number and length of seal extensions used. A seal extension is simply a length of pipe without any seals.

Sealbore extensions are designed to extend the polished surface of the packer bore to permit the use of longer sealing units to compensate for the contraction and/or elongation of tubing.

The ratch-latch seal assembly must be used with a ratch-latch head packer. This seal assembly is short because movement is prevented by the threaded ratch-latch arrangement.

Types of Permanent Packers

Permanent packers can be sub-divided according to the method required to set the packer. Electric Wireline, and Hydraulic, are the two setting methods available.

Wireline Set

The wireline set packer is the most commonly used of any type of permanent packer. It can be run and set quickly and accurately at a pre-determined depth. After the packer is set, a seal assembly and tubing are then run into the well. Once the seal assembly seals into the packer, tubing length is adjusted at the surface (spaced out) and the well is then completed.

Some common conditions and/or applications for the electric wireline set permanent packer to include:

- Set quickly and accurately – by means of an adapter kit, the packer is attached to a setting tool and collar locator which permits accurate depth correlation. The reference points for critical spacing of equipment, sump packer for gravel pack, and isolating “close together formations” are a few examples of accuracy.

- Shallow set capability – minimum depth setting should be limited by milling requirements.

- With the addition of accessory equipment, can be used as a temporary bridge plug (Cement Retainer Plug). Formation taking fluid or fracing a zone above the packer are typical applications for this capability.

- If tension, compression, or neutral space (Check Neutral Point Calculations In Drill String) out is required on the tubing.

- Able to accommodate large tubing movements with floating seals or travel joint arrangements.

- High corrosion application – due to the fact of limited component exposure, a relatively small percentage of the packer requires costly corrosion-resistant alloy usage thus reducing expense.

- Tubing is easily pulled (pipe tripping) with no or very limited tubing rotation required depending upon seal assembly configuration.

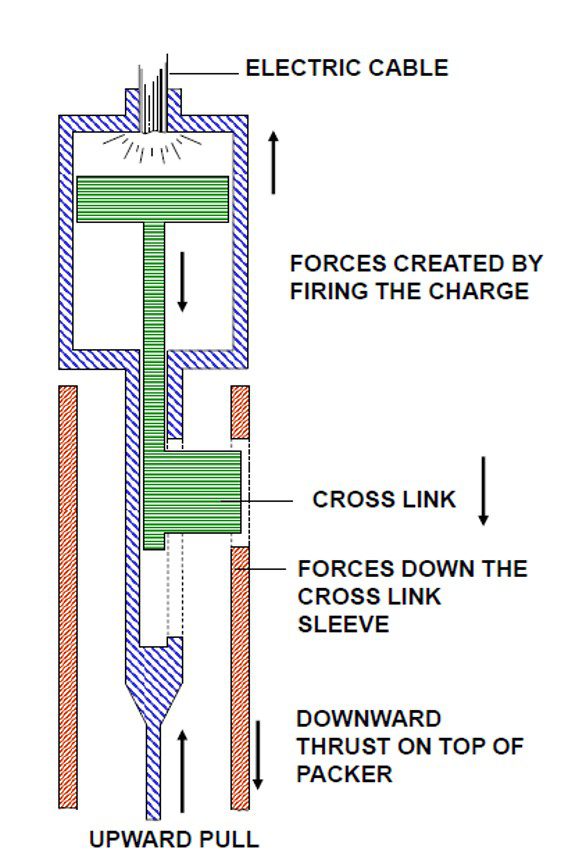

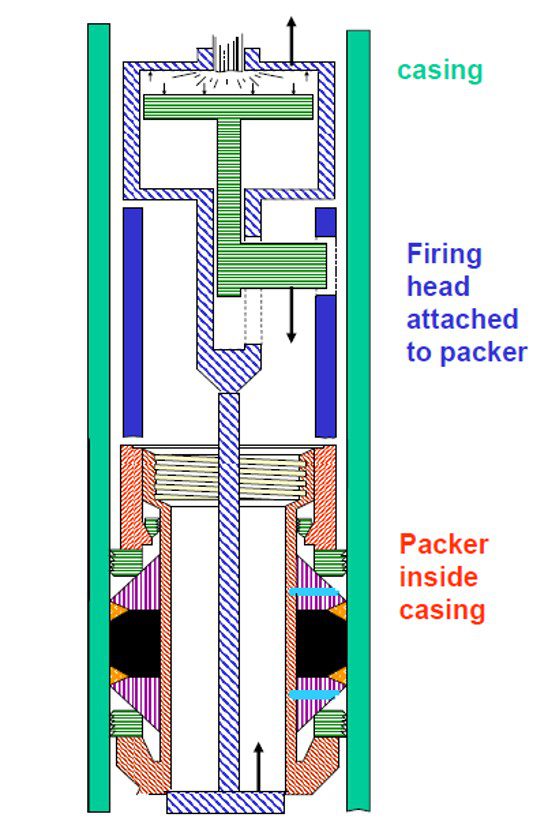

- Tubing conveyed perforating – permanent packers are ideally suited for this application in the fact that shock forces generated by the perforator will not accidentally release a permanent packer. The strength of the electric wireline will dictate the amount of gun assembly possible.

- Zone testing and stimulation work are other common applications for wireline set permanent packers.

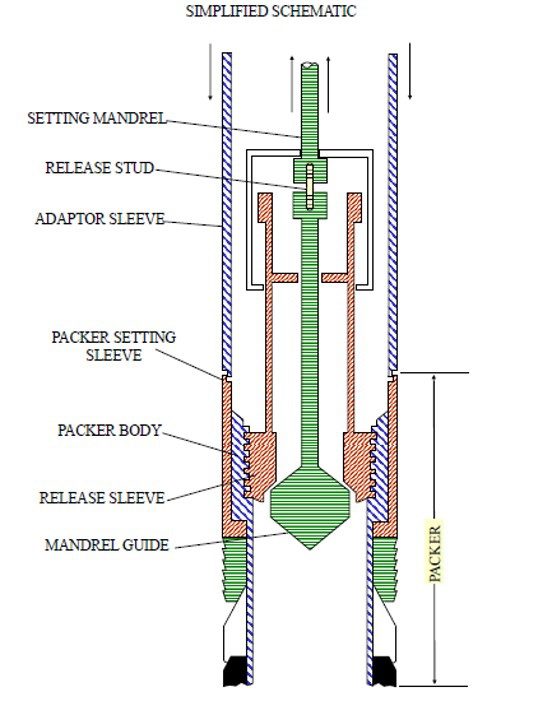

Hydraulic Setting Tool

There are instances when it is desirable to run a wireline set packer, however, hole conditions may prevent using the electric line. To accommodate the running of an electric wireline set packer, a hydraulic setting tool may be used. The hydraulic setting tool takes the place of the electric line setting tool when conditions so dictate. The packer is attached to the hydraulic setting tool and runs in the well on the pipe. Once in depth, a ball is dropped through the pipe into the setting tool. Hydraulic pump pressure activates the setting tool causing the packer to set. The hydraulic setting tool and workstring are then pulled out of the well and production seals and tubing are run to complete the well.

Some conditions which may require using a hydraulic setting tool are:

- Assembly weight. If the packer and attached equipment weigh more than the electric wireline can support, the assembly may be run and set on pipe using the hydraulic setting tool.

- Tight spots in the casing. The weight of the workstring can be used to “push” the packer through a tight spot in the casing. This is a very sensitive situation and extreme care and slow running speed should be implemented.

- Seal assembly on the bottom of the packer assembly. If a previously set lower packer is in place, the seals for the lower packer may have to be pushed into that packer using the workstring weight.

- High angle of deviation. As the angle of deviation (directional drilling) becomes greater, a point is reached where the packer will no longer “slide” down the well. This condition requires running the packer on the pipe.

- Heavy mud in the well. A thick, viscous mud (Mud properties) may prevent the packer assembly from falling on its own. Again, pipe weight may be required to push the packer assembly downhole.

NOTE OF CAUTION: The ball required to pressure activate the hydraulic setting tool may have to be circulated in place. Circulation must be done at a very slow rate so as not to prematurely shear the ball catcher seat in the hydraulic setting tool.

Hydraulic Set Permanent Packer

The hydraulic set permanent packer is run in the well on the tubing. This type of packer contains a piston/cylinder arrangement usually located in the lower end of the packer. A plugging device must be installed in the tubing below the packer. This plugging device is usually a ball catcher sub or a wireline landing nipple. The entire assembly (seal arrangement, packer, plugging device) must be made up on the surface before the packer is run into the well. Once the proper depth is reached and the plug in place, pressure applied down the tubing sets the packer.

There are two major inherent advantages associated with the hydraulic set permanent packer. These are:

- One trip operation. The packer may be run to depth and the Christmas tree installed before setting the packer. This is advantageous when rig time and cost is of major concern.

- Large flow volumes required. An upper polished bore receptacle (PBR) or overshot seal assembly is used with this type of packer. There is no seal assembly in the packer’s mandrel, thus providing a larger flow area.

Primary applications for hydraulic set permanent packers include:

- Heavy hang weight

- Large flow volumes desired

- Highly deviated well

- High temperatures and/or pressures

- Heavy mud in the well