The Drilling BHA is a very slender structure with a length-to-width ratio exceeding 500. Buckling will occur at high WOB. The buckling of the BHA string hurts overall drilling performance. It induces extra friction, leads to additional loading of components, and can induce violent dynamic behavior in the BHA, which can cause tool or drill string failures.

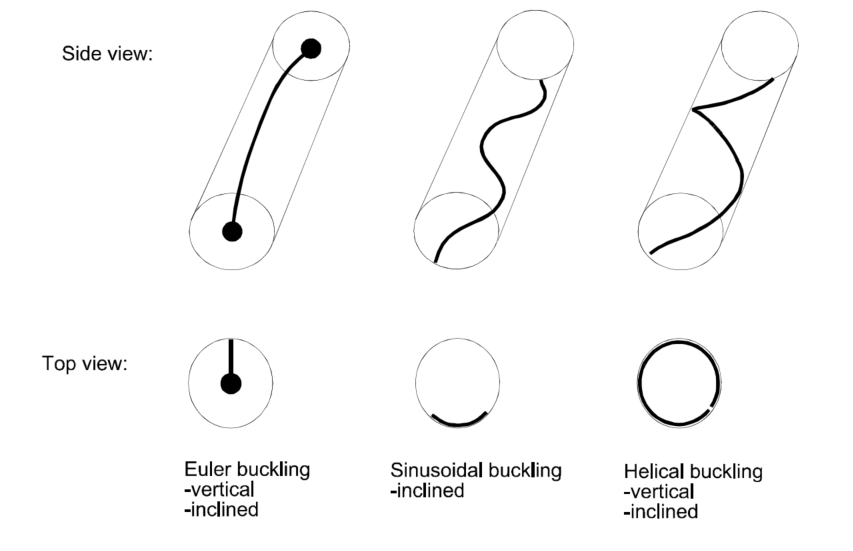

In general, three types of BHA buckling can be distinguished, see Figure 1:

- Euler buckling for an unsupported section, for instance, a drill collar section between two stabilizers in a vertical hole.

- When drilling at an angle, the drill string may experience sinusoidal buckling, which is when it becomes deformed in a wavy pattern on the lower side of the borehole. This buckling is typically the initial stage and occurs at a relatively low compressive force, making it relatively harmless.

- Once the compressive force, or the WOB, is further increased, the drill string will snap into the helical buckling shape, where the drill string is pushed into (full circumferential) contact with the borehole wall along its entire length.

Nowadays, Many software programs provide the means to calculate the maximum allowable weight-on bit, at which the BHA will not buckle. Standard torque drag software such as MODRILL should be used to investigate the buckling risk in other parts of the string. Torque drag software normally cannot be used to investigate the buckling stiffness of the BHA. Find more info in the drill string design article.

BHA Buckling Analysis in Drilling

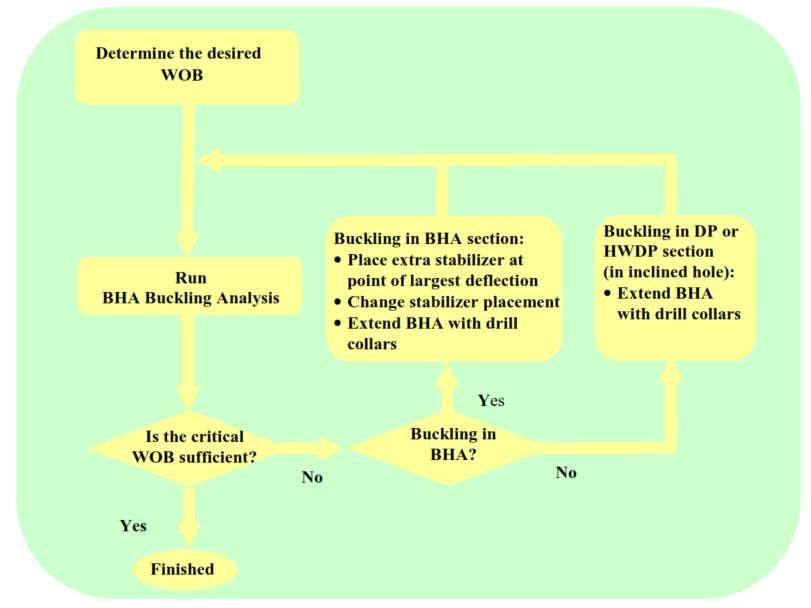

Buckling of the drill string can occur in the BHA and/or the pipe section, depending on the good profile and operating conditions. BHA Buckling analyses compute the Euler and sinusoidal buckling weight-on bits. It also checks when the drill pipe section directly above the BHA will become helically buckled. Standard torque drag software should be used to investigate the buckling risk in the non-BHA parts of the string. When sinusoidal buckling of the drill pipe section occurs at a WOB that is too low for proper bit performance, sinusoidal buckling of the pipe section can be accepted. In such a case, the WOB at which the drillstring will experience helical buckling acts as the upper limit.

It is often most convenient to run the BHA Buckling Analysis application before the lateral drilling vibration calculation to ensure that the underlying assumption of the lateral vibration calculation, a non-buckled string, is met. Check the useful flow chart below.

References

- Analysis of Sinusoidal Buckling of String in Vertical Wells Using Finite Element Method Paper, Mehmet Cebeci; ismail Hakki Gücüyener; Mustafa Versan Kök

- Pipe Buckling in Inclined Holes April 2013, Journal of Petroleum Technology, 36(10):1734-173