The cement evaluation is necessary for determining the zonal isolation and the top of cement. The position of the top of cement can be established in three ways:

- By the pressure differential method.

- By temperature survey.

- By Electronic logging (USIT/CBT logging runs)

Comparison of the actual TOC with the intended TOC may give an indication that losses (Check also Mud Losses) (unexpectedly low TOC) or channeling (unexpectedly high TOC) have occurred. The TOC can also be found during the evaluation of the zonal isolation achieved.

Bump Pressure Method

As the cement rises in the annulus (Check also: Primary Cementing Operations & Procedure) the density of the cement (Oil & Gas Cement Properties) and the drilling fluid will create a differential pressure. If the displacement rate is reduced shortly before the top cementing plug bumps, annular friction is minimized and this differential pressure between the annulus and the inside of the casing can be determined. This gives an estimate of the height of the cement based on the hydrostatic pressure exerted by both columns.

Temperature Survey For Cement Evaluation

Cement sets using an exothermic reaction, i.e., heat is generated during the setting of cement. This heat is generated for a period of six to twenty hours after mixing. The heat of the chemical reaction increases the temperature of the displacement fluid inside the casing, which can be measured using a temperature survey.

The survey is best carried out four to twelve hours after the cementation. Care must be taken to ensure that the contents of the casing are not disturbed prior to surveying. A logging tool is lowered into the hole and this records the temperature gradient. A sudden change in temperature indicates the top of the cement.

Evaluation of Cement Zonal Isolation

Good zonal isolation depends on good bonds between the casing and the cement and between the formation and the cement. The cement sheath must extend all the way around the circumference of the casing i.e. no channeling.

The most widely used method of assessing the isolating quality of cementation is the Cement Bond Log (CBL). It is commonly supported by the Variable Density Log (VDL log), although in some areas these logs have been replaced by more advanced specialist logs such as the CBT (cement bond tool) / CET (cement evaluation tool).

Fluid movement behind the casing can be detected directly by a temperature survey or other specialist logs e.g. the Noise Log. Direct evaluation of cementation can also be made by inflow, production or communication tests, but these are beyond the scope of this article.

CBL/VDL Log

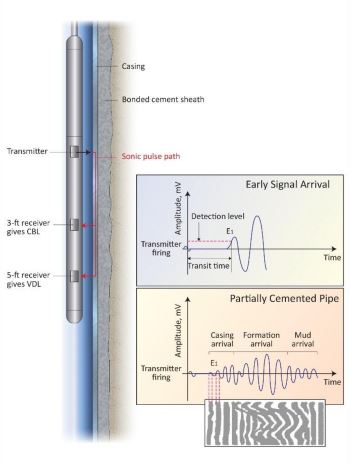

The CBL evaluates the bonding between cement and casing and the evaluation of the bonding between cement and formation is by VDL. Both logs use a sonic tool to evaluate the cement quality. Acoustic waves are sent by a transmitter towards two receivers, 0.9 m (3 ft) and 1.5 m (5 ft) below, on the sonic tool.

The waves traveling along the casing are attenuated when energy is lost to the environment of the casing i.e. when the bond is good. The lost energy is transmitted via the bond and the cement to the cement/formation interface and further into the formation. The CBL is a recording of the amplitude of the first receipt of energy by the 0.9 m (3 ft) receiver. This is the energy that has travelled through the casing.

The recorded amplitude of the CBL depends on four factors:

- Compressive strength of cement.

- Sector and thickness of annular cement fill.

- Quality of bond between casing and cement.

- Casing diameter and wall thickness.

Read more on Cement Bond Log, VDL Log, Cement Evaluation Tool Articles