A tubing-retrievable subsurface safety valve (TRSCSSSV) is run as an integral part of the completion string. The equipment requirements for the oil and gas TRSV system are: the TRSV assembly, hydraulic control line and fittings, and a hydraulic control manifold. Like the wireline retrievable safety valve WRSV, the control line is attached between the TRSV and the tubing hanger.

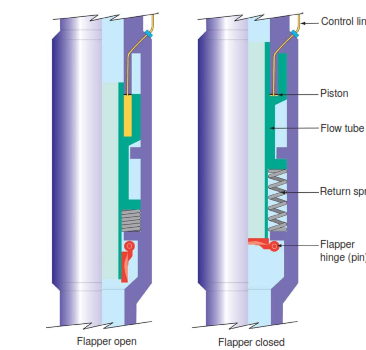

When running a TRSV, hydraulic pressure is applied to the control line holding the valve open to prevent pressure locking when the tubing string engages a packer or liner hanger. The valve of this hold-open pressure is provided in the manufacturer’s design and test pressures.

Many oil and gas companies recommend that the valves be tested at intervals not exceeding 6 months

Tubing Retrievable Safety Valve Applications

It is advisable to avoid restricting the through diameter in wells with substantial production rates. Additionally, for gas wells especially, this restriction near the surface coincides with a zone where pressure and temperature conditions may favor hydrate formation. Therefore, this type of oil and gas well is preferably equipped with TRSV safety valves that provide an inside through diameter the same as that of the tubing. The production string must, however, be pulled out to change the valve. The valve is usually associated with a tubing anchor and a disconnection system that allows only the upper part of the tubing and the valve to be pulled out.

Because of their design, the valves can be locked open:

- Sometimes temporarily, an asset during wireline operations in the well,

- Definitely, if the valve should lose its tightness, for example.

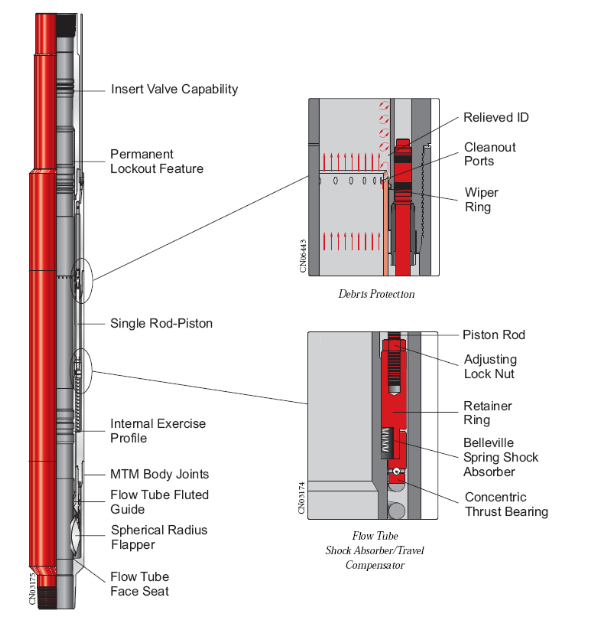

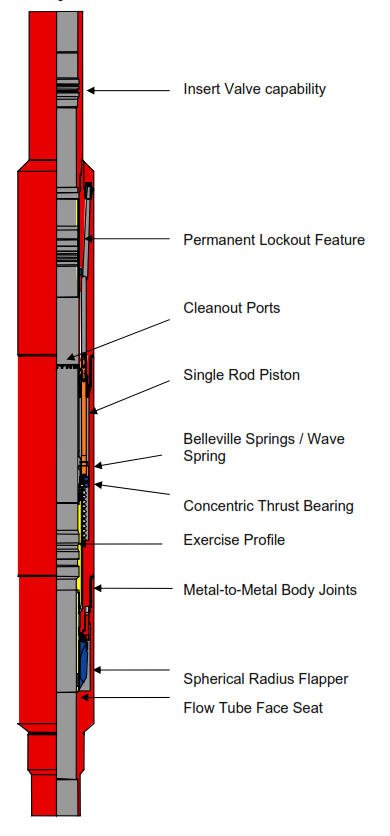

In the second case, a landing nipple machined in the valve body may allow a wireline retrievable valve to be inserted and controlled by the same hydraulic line. This makes it possible to keep well in safe conditions while waiting for a workover operation if a tubing retrievable valve (TRSCSSSV) has failed. In subsea completions, two tandem valves can be run together, each operated independently of the other.

Tubing Retrievable Safety Valve Advantages

- Control line fluid is not exposed to well fluids during installation or retrieval.

- The tubing retrievable safety valve (TRSCSSSV) is made up in the tubing string.

- The valve is always in the well. It is not removed for any wireline work.

- Wireline operations can carry out through the tubing valve.

- If the valve should malfunction, a wireline retrievable safety valve can be installed inside of it.

- The valve can usually be bridged during severe workover operations, such as acidizing or fracturing.

- Flow rates through the valve are the same as for the tubing because the two ID’s are the same.

Disadvantages

- Accessibility: to retrieve a tubing retrievable safety valve, the tubing must be retrieved.

TRSV Failure

If a TRSV develops a failure while in service, an option to allow the oil and gas well to continue in production is to install a WRSV insert valve within the TRSV using a lockout tool, insert wireline retrievable safety valve (WRSV) and wireline installation and retrieval tools.

NOTE: If the reason for the TRSV failure is due to a leakage of the control line, then this remedy is not appropriate as the WRSV also relies on control line integrity.

The TRSV insert procedure locks open the valve mechanism with the lockout tool, which also opens communication to the control line and installs the insert valve precisely as the standard WRSV installation procedure.

This option is a cost-effective method of trscsssv safety valve reinstatement but may reduce production due to its smaller bore size. If this was unacceptable, a workover would be necessary to plug and kill the well and pull the completion.

TRSCSSSV Conclusion

Most modern completions use tubing retrievable safety valves, except where conditions and rates are benign. These valves are more reliable than wireline retrievable versions, provide fewer restrictions, and do not need to be pulled for every well intervention.

Alternately, on easily accessible land wells where servicing and workover methods are relatively much less costly, servicing can be conducted almost on demand. This may lead to selecting a wireline retrievable type safety valve rather than a tubing retrievable type (TRSCSSSV), as in the event of failure; the valve can be replaced cheaply without requiring a workover.

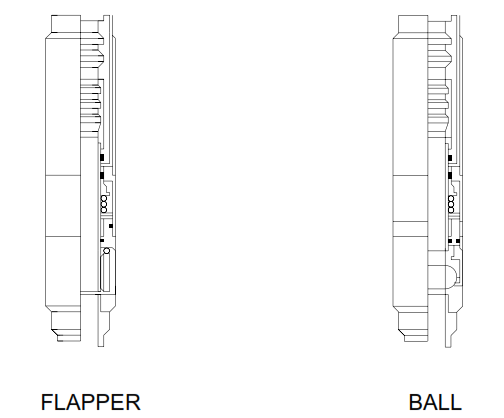

Some older designs of TRSCSSSV use ball valves instead of flappers. However, the simplicity of flapper systems means that ball valve designs are now rare (they are still used in deployment valves where being able to pressure test from above is helpful). We can pump through almost all flapper valves, which is useful if the valve fails and requires a hydraulic kill.